Nowadays, aluminum die casting is widely used in various industries like automotive, industrial, and telecommunications. It’s often used to produce electrical, hydraulic, lighting components, etc. No matter you want know more about aluminum die casting, or would like to get some useful tips on whether it is the best choice for your application, you have come to the right place!

The aluminum die-casting process is a widely used manufacturing technique that allows for the creation of complex and intricate metal components. It offers numerous advantages, such as cost-effectiveness, design flexibility, and high production rates. However, understanding the aluminum die-casting process can be challenging, especially for those who are new to the industry. That's why we have created this comprehensive guide to provide you with all the information you need to know about the aluminum die-casting process. Whether you are a seasoned professional or a beginner, this ultimate guide will serve as your best reference for mastering aluminium die castings.

The aluminum die-casting process allows for the production of parts with precise dimensions, intricate details, and a high degree of complexity that would be difficult or costly to achieve through other manufacturing methods. Here is an overview of the process:

A steel mold, called a die, is created with the desired shape of the part to be produced. The die consists of two halves, the "cover die" and the "ejector die", which fit together to form a cavity.

Aluminum alloy ingots are melted in a furnace at high temperatures. Once the molten aluminum reaches the desired temperature and consistency, it is injected into the die through a system of channels and gates under high pressure.

The molten aluminum quickly fills the cavity and cools down, solidifying into the shape of the desired part. The cooling time depends on the size and complexity of the part.

After the aluminum solidifies, the cover die and ejector die are separated, and the part is ejected from the die cavity using ejector pins or plates.

The part may undergo additional trimming and finishing processes to remove excess material, smooth rough edges, or improve surface quality. This can be done through various methods such as machining, grinding, or sandblasting.

The finished parts are inspected for defects, dimensions, and quality to ensure they meet the required specifications. Any defective parts can be scrapped or reworked.

The aluminum die casting process offers several advantages over alternative manufacturing methods. This makes it a popular choice in various industries.

The aluminum die casting allows for the production of parts with intricate details and complex shapes. This is achieved through the use of reusable steel molds, which can be designed to accommodate various features such as holes, threads, undercuts, and complex geometry. This versatility makes aluminum die casting suitable for applications where precise dimensions and intricate designs are required.

The aluminum die casting process requires minimal post-processing operations. This is because the molten aluminum fills all the intricate details of the mold under high pressure, resulting in a precise and accurate reproduction of the desired part. As a result, there is less need for additional finishing operations such as machining or surface treatment, reducing production time and cost.

The aluminum die casting parts offer excellent dimensional accuracy and repeatability. The steel molds used in the process ensure consistent quality across large production runs, minimizing variations in part dimensions. This level of precision is crucial in industries where tight tolerances and consistent quality are required.

The aluminum die casting parts are known for their high strength-to-weight ratio. This makes them suitable for applications where lightweight yet durable components are needed. The use of aluminum alloys further enhances this property, allowing for part customization to meet specific application requirements.

Due to its rich advantages and rapid development, aluminum casting parts are gaining much more popularity. According to Grand View Research, Aluminum Casting Market was valued at $58.91 Bn in 2020 and is projected to reach $103.17 Bn by 2028, growing at a CAGR of 7.27 % from 2021 to 2028. Here are some of the top applications of die casting aluminum parts.

Aluminum casting parts are extensively used in the automotive industry, including engine components, transmission cases, suspension parts, and wheels. Aluminum's lightweight nature helps improve fuel efficiency and reduce overall vehicle weight.

Aluminum casting parts find significant use in the aerospace industry for applications such as aircraft bodies, wing structures, engine components, and landing gear parts. Aluminum's high strength-to-weight ratio is crucial in aerospace applications where weight reduction is a primary concern.

Many consumer electronic devices, such as smartphones, laptops, and tablets, incorporate aluminum casting parts in their designs. These parts provide structural support, heat dissipation, and aesthetic appeal.

Aluminum casting parts are widely utilized in industrial equipment like pumps, compressors, valves, and generators. Aluminum's corrosion resistance and excellent thermal conductivity make it suitable for various industrial applications.

Aluminum casting parts are employed in electrical equipment, including power distribution systems, switchgear, and transformer housings. This dues to their electrical conductivity and heat dissipation capabilities.

Aluminum casting parts are used in the marine industry for manufacturing boat components, ship structures, and offshore equipment. Aluminum's resistance to corrosion in marine environments makes it an ideal choice.

Aluminum casting parts are also used in the furniture industry to manufacture lightweight and durable furniture pieces. Additionally, aluminum casting is used to create decorative items, architectural accents, and lighting fixtures.

Actually, these are just a few examples of the wide-ranging applications of aluminum casting parts. The versatility, lightweight nature, and excellent mechanical properties of aluminum make it a preferred choice for many industries seeking reliable and cost-effective solutions.

When designing aluminum die casting parts, there are several important considerations to keep in mind to ensure successful production and optimal performance. The design choices made during the initial stages can greatly impact the final product's quality, functionality, and cost-effectiveness. Here are some key design considerations for aluminum die casting parts:

Maintaining uniform wall thickness is crucial for aluminum die casting parts. Varying wall thicknesses can lead to uneven cooling and shrinkage, causing defects such as warping, porosity, or distortion. Designers should aim for an even wall thickness throughout the part to achieve consistent and reliable results.

Ribs and bosses are commonly used in aluminum die casting parts to provide additional strength or support. However, their design and placement can significantly affect the part's overall integrity. Ribs should have tapered edges and adequate thickness to ensure proper filling and reduce the risk of premature solidification. Similarly, bosses should be designed with proper draft angles and wall thickness to avoid shrinkage and improve structural integrity.

Draft angles are essential for easy ejection of the part from the die. Without sufficient draft angles, the part may get stuck or damaged during the ejection process. Designers should incorporate appropriate draft angles (typically 0.5-1.5 degrees per side) to facilitate smooth ejection and prevent defects.

Sharp corners can create stress concentrations and increase the likelihood of cracks or fractures in aluminum die casting parts. To enhance strength and minimize stress concentrations, designers should incorporate generous corner radii. Rounded edges also facilitate mold filling and ejection, resulting in improved part quality.

Fillets and chamfers are commonly used to enhance part aesthetics, improve mold filling, and reduce stress concentrations. Well-designed fillets and chamfers not only improve the overall appearance but also contribute to the part's structural integrity and ease of manufacture.

Undercuts and slides refer to features that cannot be directly formed using a single die-casting operation. Including undercuts or slides in the design may require additional tooling and increase production complexity and cost. Whenever possible, designers should aim to minimize or eliminate undercuts and slides to streamline the manufacturing process.

Considerations for surface finishes and textures should be made during the design phase. Depending on the intended application and aesthetic requirements, designers may choose to incorporate specific textures, polish, or coatings to achieve the desired visual and functional characteristics of the aluminum die casting part.

By carefully considering these design aspects, designers can optimize the manufacturability, efficiency, and end-use performance of aluminum die casting parts. Collaborating with experienced die-casting engineers and leveraging advanced design software can further enhance the design process, ensuring the successful production of high-quality aluminum die casting components.

Richconn is a renowned aluminum die casting service provider known for their expertise in delivering high-quality and reliable die casting solutions. It takes pride in its strong commitment to customer satisfaction and a focus on precision engineering. It offers various aluminum parts with a wide range of dimensions - from a few grams to as much as you desire.

Good News! Here is what you can get from Richconn.

Quite cost-effective

Professional engineer experts to perfectly complete your project, from prototyping to large-scale production

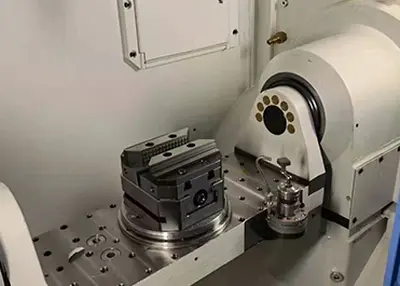

Employ the latest CAD/CAM software, simulation tools, and CNC machines to ensure precise and efficient casting results

Follow stringent quality control measures to ensure the highest level of product quality

Offer a wide range of aluminum die casting services, catering to different sizes, complexities, and specifications

Streamline the manufacturing processes to ensure efficient production and fast turnaround time without compromising on quality

Richconn is recognized as the best aluminum die casting service provider due to their extensive experience, advanced technology, commitment to quality, versatility, expert team, timely delivery, and customer satisfaction. Richconn will give you top-notch custom aluminum die cast service.

With this ultimate guide on aluminum die casting, we hope you can have a better understanding of aluminum die casting. If you are looking for a trusted partner to handle the aluminum die casting process, then Richconn must be your best choice. As a professional CNC China company, Richconn provides professional diecasting service, which ensures you will get the exact part from design to production. So, start your project NOW and get instant quote today!

What Is Zinc Alloy? The Complete Basics to Get StartedOctober 8, 2023This article covers the information you need to watch out for in product design and part manufacturing when using zinc alloy. Take a deeper look into zinc alloy!view

What Is Zinc Alloy? The Complete Basics to Get StartedOctober 8, 2023This article covers the information you need to watch out for in product design and part manufacturing when using zinc alloy. Take a deeper look into zinc alloy!view Difference Between Hot Rolled and Cold RolledDecember 4, 2023Steel comes in a variety of grades, sizes, shapes and finishes - the World Steel Association lists more than 3,500 different grades of steel, most with unique properties. The variety of steel grades means that steel can be used in a wide range of applications for foundations, appliances, vehicles, wind turbines and many more.view

Difference Between Hot Rolled and Cold RolledDecember 4, 2023Steel comes in a variety of grades, sizes, shapes and finishes - the World Steel Association lists more than 3,500 different grades of steel, most with unique properties. The variety of steel grades means that steel can be used in a wide range of applications for foundations, appliances, vehicles, wind turbines and many more.view In-Depth Overview: What Are Non-Ferrous Metals?August 7, 2023Metals may be found everywhere and are used for a variety of purposes. There are two different types of metals, ferrous and non-ferrous—based on how much iron they contain. Non-ferrous metals are a c...view

In-Depth Overview: What Are Non-Ferrous Metals?August 7, 2023Metals may be found everywhere and are used for a variety of purposes. There are two different types of metals, ferrous and non-ferrous—based on how much iron they contain. Non-ferrous metals are a c...view Basic of Gear Manufacturing: A Guide to Learn about Gear Production ProcessesAugust 29, 2023There is no single process for manufacturing gear because several processes are required based on the type and application. The gears need to be in absolutely perfect condition to adapt to strenuous c...view

Basic of Gear Manufacturing: A Guide to Learn about Gear Production ProcessesAugust 29, 2023There is no single process for manufacturing gear because several processes are required based on the type and application. The gears need to be in absolutely perfect condition to adapt to strenuous c...view 3-Axis Vs 4-Axis Vs 5-Axis CNCJuly 21, 20233-axis machiningThree axis CNC machining is the most basic, commonly used in the machinery manufacturing industry is one of the most important processing methods. Common understanding is: accurate lin...view

3-Axis Vs 4-Axis Vs 5-Axis CNCJuly 21, 20233-axis machiningThree axis CNC machining is the most basic, commonly used in the machinery manufacturing industry is one of the most important processing methods. Common understanding is: accurate lin...view How do you charge for sleeve parts machining?October 31, 2023Sleeve parts machining charges will be involved in the structural design, machining process, hole size, material selection and other requirements, any one of the different processing needs will lead to a great difference in price, so the need for a relatively accurate quote must provide a complete design drawings, engineers will be based on the design of the drawings labeled materials, dimensions, process, accuracy, structure, table at the detailed parameters such as calculating the accurate quote.view

How do you charge for sleeve parts machining?October 31, 2023Sleeve parts machining charges will be involved in the structural design, machining process, hole size, material selection and other requirements, any one of the different processing needs will lead to a great difference in price, so the need for a relatively accurate quote must provide a complete design drawings, engineers will be based on the design of the drawings labeled materials, dimensions, process, accuracy, structure, table at the detailed parameters such as calculating the accurate quote.view