Welcome to Richconn's comprehensive guide on "Machined Bar." Whether you're an engineer seeking in-depth knowledge, a manufacturer exploring material options, or a student in the quest for information, this guide has you covered. In the world of CNC machining, machined bars are essential components. They offer precision, strength, and versatility, making them invaluable in various industries.

Let's embark on a journey to explore machined bars, from their fundamentals to advanced applications. By the end of this guide, you'll have a solid understanding of machined bars and how they can meet your specific needs.

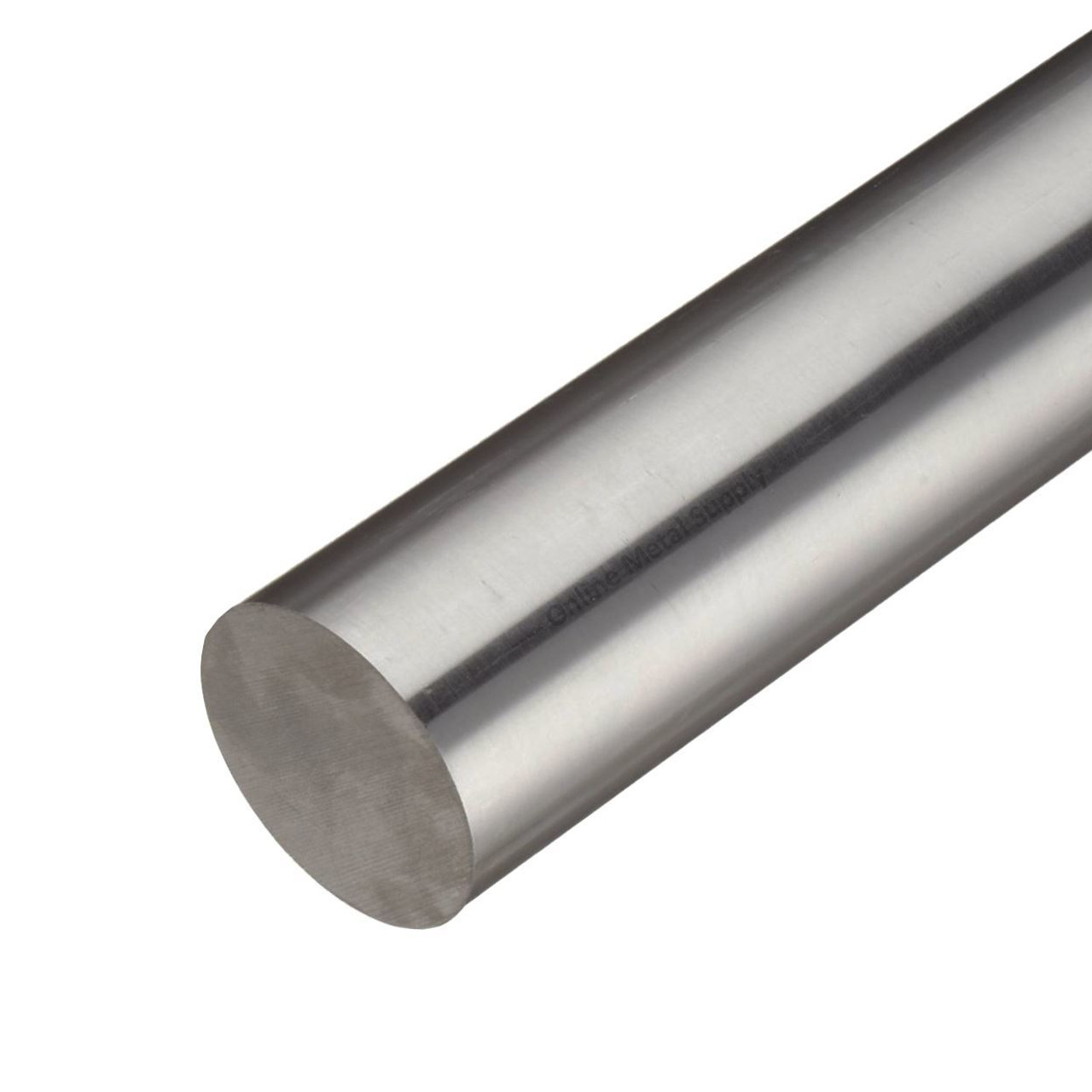

Machined bars are the backbone of precision engineering. They are cylindrical rods meticulously crafted to meet specific requirements. These bars come in various materials, sizes, and shapes, making them versatile for a wide range of applications. Whether you need a steel bar for structural support or an aluminum bar for aerospace components, machined bars play a crucial role.

But what sets them apart? Machined bars are distinguished by their exceptional precision and uniformity, ensuring consistent quality in every piece.

Machined bars are the unsung heroes in various industries, serving as critical components in precision engineering. They are engineered with a high degree of precision to ensure consistency and reliability. The following table provides a glimpse of how machined bars are essential in different applications:

| Industry | Application | Machined Bar Usage |

|---|---|---|

| Mechanical | Shafts, Gears, and Bushings | Provide stability, load-bearing support, and rotation |

| Construction | Structural Components | Used for structural reinforcement and architectural details |

| Automotive | Engine Components and Suspension Systems | Contribute to performance and durability |

| Aerospace | Aircraft Parts and Defense Equipment | Ensure precision, reliability, and safety |

In each of these industries, machined bars are integral to achieving high-performance standards. Their precision and consistency make them invaluable.

Machined bars come in a wide range of materials, each with its unique properties. Some of the common materials include:

Steel: Known for its high strength and durability, steel machined bars are ideal for heavy-duty applications.

Aluminum: Lightweight and corrosion-resistant, aluminum bars are commonly used in aerospace and automotive industries.

Stainless Steel: Offers excellent resistance to corrosion and heat, making it suitable for diverse applications.

Brass: Known for its excellent electrical conductivity and corrosion resistance.

Copper: Ideal for applications requiring high electrical and thermal conductivity.

The choice of material depends on the specific requirements of your project.

Machined bars are available in various sizes and shapes to suit different applications. They can range from small-diameter rods to large-diameter bars, and they come in round, square, or hexagonal shapes, among others.

Understanding the physical and chemical properties of machined bars is essential, especially when you're selecting the right material for your project.

Machined bars are known for their exceptional strength and hardness, making them reliable components in a wide range of applications. The strength of machined bars is influenced by factors such as material selection and the manufacturing process. Here are some key considerations:

Material Influence: The choice of material significantly impacts the strength of a machined bar. For example, steel machined bars exhibit exceptional tensile strength, making them ideal for load-bearing applications.

Heat Treatment: Heat treatment processes can further enhance the strength and hardness of machined bars. Processes like quenching and tempering can improve their mechanical properties.

Precision Machining: The precision with which machined bars are manufactured ensures uniform strength and hardness throughout the length of the bar.

Corrosion resistance is a critical property, particularly in applications where machined bars are exposed to harsh environments or corrosive substances. The following table highlights the corrosion resistance of common materials used in machined bars:

| Material | Corrosion Resistance |

|---|---|

| Steel | Prone to corrosion without proper treatment |

| Stainless Steel | Exceptional corrosion resistance due to chromium content |

| Aluminum | Naturally corrosion-resistant due to the formation of a protective oxide layer |

| Brass | Good resistance to atmospheric and water corrosion |

| Copper | Susceptible to corrosion in humid and acidic environments |

The corrosion resistance of a machined bar's material plays a vital role in its durability and performance in specific applications.

Machined bars may operate in a wide range of temperatures and environmental conditions. Understanding how different materials behave in these conditions is crucial:

Temperature Variability: Some materials, like steel, can withstand extreme temperature fluctuations without significant structural changes. Others, like aluminum, are sensitive to temperature variations.

Moisture and Humidity: Materials like brass and copper are susceptible to corrosion in humid environments, making them less suitable for applications in these conditions.

Chemical Exposure: Consider the compatibility of machined bar materials with chemicals they may come into contact with in their applications.

The chemical composition of a machined bar's material determines many of its properties. For instance, the addition of alloying elements to steel can improve its strength and corrosion resistance. Stainless steel, for example, contains chromium for enhanced corrosion resistance. Understanding the chemical composition is vital when selecting the right material for your project.

The composition of a machined bar's material is typically specified to ensure consistency and quality.

Machined bars find applications in diverse industries, offering precision and reliability. Understanding where and how they are used can help you make informed decisions.

In the realm of mechanical engineering, machined bars are essential components in various applications. Let's explore some key uses:

Shafts: Machined bars serve as the backbone of rotating shafts in machinery, ensuring stability and smooth operation.

Gears: Precision gears are critical for transmitting motion and torque. Machined bars often provide the core structure for these gears.

Bushings: In applications where low friction and wear resistance are required, machined bars are used as bushings to reduce friction between moving parts.

The construction industry relies on machined bars for various structural and architectural applications:

Structural Components: Machined bars are employed in structural elements to reinforce and enhance the stability of buildings and infrastructure.

Architectural Details: They are used for decorative purposes, such as railings, balusters, and ornamental designs, where precision and aesthetics are essential.

In the automotive sector, precision and performance are paramount, making machined bars a valuable resource:

Engine Components: Many engine parts, like crankshafts, pistons, and camshafts, are crafted from machined bars for their durability and precision.

Suspension Systems: The suspension system relies on machined bars for stabilizers and control arms, ensuring optimal handling and ride quality.

The aerospace and defense industries demand the utmost precision and reliability. Machined bars play vital roles in these sectors:

Aircraft Parts: From wing components to landing gear, machined bars are used to ensure the safety and performance of aircraft.

Defense Equipment: Critical defense equipment, including missile components and military vehicles, relies on the precision and durability of machined bars.

One remarkable aspect of machined bars is their adaptability across industries. Whether you're designing a complex mechanical system, constructing a skyscraper, building a high-performance sports car, or developing cutting-edge defense technology, machined bars are there to meet your precision engineering needs.

Let's delve into detailed success stories to understand how machined bars have transformed projects:

Case Study 1: The Automotive Marvel

In this case, we explore how machined bars played a pivotal role in improving the performance and safety of a renowned sports car.

Challenge: A leading automotive manufacturer sought to enhance the performance and safety of their flagship sports car. The challenge was to create an engine that delivered superior power, while maintaining reliability.

Solution: Engineers turned to machined bars for critical engine components. The use of precision-machined bars ensured optimal engine performance, withstanding high RPMs and intense heat.

Result: The sports car not only achieved exceptional power but also exhibited remarkable reliability, attracting rave reviews from both experts and enthusiasts. The project was a testament to the importance of precision in automotive engineering.

Case Study 2: Building Tomorrow's Skyscrapers

Learn how the construction industry leveraged machined bars to ensure the structural integrity and aesthetics of modern skyscrapers.

Challenge: In the construction of cutting-edge skyscrapers, architects and engineers faced the challenge of designing structures that combined aesthetic appeal with structural integrity.

Solution: Machined bars were used to create intricate architectural details and reinforce critical structural components. Their precision allowed for seamless integration into the building's design.

Result: The skyscrapers not only stood as marvels of modern architecture but also boasted robust structural stability, meeting safety standards and surpassing aesthetic expectations.

Case Study 3: Aerospace Excellence

Explore how the aerospace industry's quest for precision and reliability led to breakthroughs in aircraft design.

Challenge: The aerospace industry continually seeks to enhance aircraft performance while maintaining safety and reliability. Precision engineering is of utmost importance in this sector.

Solution: Aerospace engineers turned to machined bars for the production of critical aircraft components. The precision of machined bars contributed to reduced weight and increased fuel efficiency.

Result: Aircraft equipped with machined bar components achieved greater fuel efficiency, performance, and safety, revolutionizing the aerospace industry.

These case studies illustrate how machined bars have been instrumental in achieving success in their respective industries, from high-performance automobiles to soaring skyscrapers and advanced aircraft.

Understanding how machined bars are manufactured sheds light on the precision and quality they offer.

The manufacturing process of machined bars begins with the careful selection and preparation of raw materials:

Material Selection: Choosing the right material is a critical decision. It depends on the intended use, environmental conditions, and the desired properties of the machined bar. Common materials include steel, aluminum, stainless steel, brass, and copper.

Material Preparation: Raw materials are inspected and prepared by cutting them into suitable lengths for the machining process. Quality control begins at this stage to ensure the material meets specifications.

Machining methods and techniques are at the heart of crafting precision machined bars:

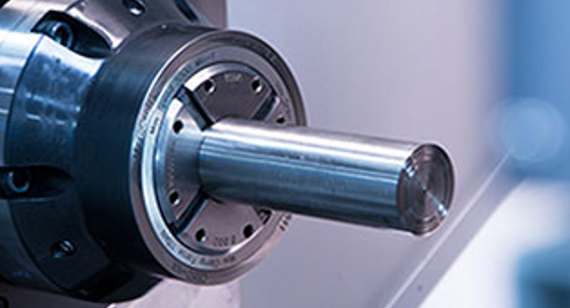

Turning: Turning is a common machining technique used to create cylindrical shapes. The material rotates, and a cutting tool removes material to achieve the desired diameter and surface finish.

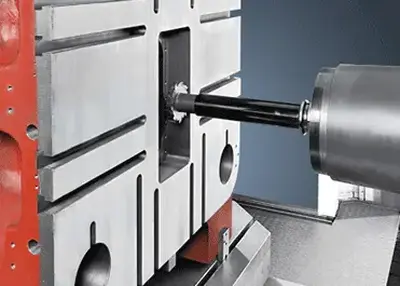

Milling: Milling is employed for creating non-cylindrical shapes, slots, and contours. The cutting tool rotates to remove material as it moves along multiple axes.

Grinding: Precision grinding is used to achieve tight tolerances and surface finish. It is ideal for creating highly accurate and smooth surfaces.

Drilling: Drilling is used to create holes in machined bars with precision and accuracy.

Quality control and inspection are integral parts of the manufacturing process:

Dimensional Accuracy: Machined bars undergo rigorous dimensional inspections at various stages to ensure they meet specified tolerances.

Surface Finish: Surface finish is examined for smoothness and free from defects.

Hardness Testing: Depending on the application, hardness testing may be performed to ensure the machined bars have the required strength.

Visual Inspection: Visual inspections are conducted to identify any surface defects or imperfections.

Non-Destructive Testing (NDT): Some machined bars may undergo NDT techniques like ultrasonic testing to identify internal flaws.

Material Analysis: Chemical analysis may be performed to verify that the material composition adheres to specifications.

One of the key attributes of machined bars is their precision and uniformity. The manufacturing process, including the use of advanced CNC machines, ensures that each bar meets strict quality standards. The result is a product that offers consistency and reliability for your projects.

Machined bars are not the only materials available. This section compares them to other materials to help you make an informed decision.

Steel is a traditional and widely used material in many applications. Let's compare it to machined bars:

Strength and Durability: Steel is known for its exceptional strength and durability, making it suitable for heavy-duty applications. Machined bars made from steel offer similar characteristics.

Corrosion Resistance: While steel is susceptible to corrosion, machined bars made from stainless steel provide excellent corrosion resistance.

Weight: Steel can be heavier than some alternative materials, impacting applications where weight is a concern.

Aluminum alloys offer lightweight and corrosion-resistant properties. Let's compare them to machined bars:

Weight: Aluminum is significantly lighter than steel, making it ideal for applications where weight reduction is critical. Aluminum machined bars provide this advantage.

Corrosion Resistance: Aluminum forms a protective oxide layer, rendering it highly resistant to corrosion. Aluminum machined bars excel in this regard.

Strength: While aluminum is lightweight, it may not provide the same level of strength as steel or stainless steel. The choice depends on the specific application.

Polymers, such as plastics, are known for their versatility and low cost. Let's compare them to machined bars:

Strength: Machined bars offer superior strength, making them suitable for load-bearing applications. Polymers may not provide the same level of strength.

Chemical Resistance: Polymers excel in chemical resistance, but machined bars, particularly those made from stainless steel, offer their own resistance to corrosive environments.

Temperature Resistance: While polymers may have limitations in high-temperature applications, machined bars can withstand a wider range of temperatures.

Selecting the right material depends on your specific project requirements. Machined bars offer the advantage of precision and uniformity, ensuring that the material consistently meets high-quality standards. When choosing between materials, consider factors like strength, weight, corrosion resistance, and temperature requirements.

The choice of material can significantly impact the performance and longevity of your project, so be sure to make an informed decision based on your specific needs.

Staying informed about market trends is essential, especially if you are considering the use of machined bars in your projects. Let's explore the current trends and opportunities in the machined bar industry.

The machined bar market is a dynamic and growing industry with a global presence. Here's an overview of its current state:

Market Size: The global machined bar market continues to expand, driven by increased demand across various industries, including automotive, aerospace, and construction.

Key Players: Leading manufacturers and suppliers are continually innovating to meet the evolving needs of customers.

Emerging Markets: Emerging markets are showing significant growth potential as industries in these regions continue to develop and invest in precision engineering.

The machined bar industry is characterized by several growth trends and opportunities:

Precision and Quality: There is an increasing demand for high-precision and high-quality machined bars, especially in industries where reliability is crucial, such as aerospace and defense.

Customization: Customers are increasingly seeking customized machined bars to meet specific project requirements. This presents an opportunity for manufacturers to provide tailored solutions.

Sustainability: Environmentally friendly materials and manufacturing processes are gaining importance, leading to the development of sustainable machined bar options.

Digitalization: The integration of digital technologies, such as CNC machining and automation, is streamlining production processes and enhancing efficiency.

As we look to the future, several developments are expected to shape the machined bar industry:

Advanced Materials: The development of advanced materials, including new alloys and composites, is anticipated to offer enhanced properties, expanding the application range of machined bars.

Digital Manufacturing: Industry 4.0 concepts are likely to play a pivotal role, leading to smart factories with integrated systems for real-time monitoring and data-driven decision-making.

Global Supply Chains: The optimization of global supply chains will continue to facilitate the availability of machined bars, enabling manufacturers to source materials efficiently.

Sustainability Initiatives: Sustainability and eco-friendly practices will influence the industry, leading to the development of greener machining processes and materials.

Keeping an eye on these trends and opportunities can help businesses make informed decisions and stay competitive in the ever-evolving field of precision engineering.

At Richconn, we specialize in CNC machining services, and machined bars are at the heart of what we do. Our commitment to quality and precision has made us a trusted partner in the industry.

Our CNC machining services are founded on expertise and experience. We take pride in our capabilities, which include:

State-of-the-Art Equipment: We employ advanced CNC machines to ensure the highest level of precision and quality.

Highly Skilled Team: Our team of skilled machinists and engineers is dedicated to delivering excellence in every project.

Customization: We understand that each project is unique. Our ability to provide customized solutions sets us apart.

Our track record of customer success speaks to the quality and reliability of our services. Here are a few examples:

Automotive Advancements: We partnered with a leading automotive manufacturer to produce precision-engineered components, contributing to the exceptional performance and reliability of their vehicles.

Architectural Excellence: Richconn played a key role in ensuring the structural stability and aesthetic appeal of several iconic skyscrapers.

Aerospace Innovations: Our CNC machining services have been instrumental in enhancing the fuel efficiency and performance of aerospace components.

These success stories reflect the trust that industry leaders place in Richconn's capabilities.

Quality control is a cornerstone of our operations. We prioritize quality at every stage of the manufacturing process:

Rigorous Inspections: Our machined bars undergo thorough inspections to ensure they meet the highest standards for precision, accuracy, and consistency.

Reliable Customer Support: We maintain open lines of communication with our customers to address their needs and provide expert guidance throughout the project.

Customer Satisfaction: We measure our success by the satisfaction of our customers, and our track record reflects their confidence in our services.

Ready to elevate your project with Richconn's expertise? Contact us today.

This comprehensive guide has taken you through the world of machined bars, from their fundamental properties to advanced applications and industry trends. Now, you're equipped with the knowledge needed to make informed decisions about using machined bars in your projects. If you're ready to experience precision and quality, don't hesitate to reach out to Richconn's CNC machining services. Your journey to excellence begins here.

Navigating the World of Horizontal Boring TechnologyNovember 23, 2023Horizontal boring technology encompasses a realm of precision and innovation within precision CNC machining. At its core, it involves the utilization of specialized machinery, notably horizontal boring machines and mills, to create intricate cavities, bores, and holes with utmost accuracy.view

Navigating the World of Horizontal Boring TechnologyNovember 23, 2023Horizontal boring technology encompasses a realm of precision and innovation within precision CNC machining. At its core, it involves the utilization of specialized machinery, notably horizontal boring machines and mills, to create intricate cavities, bores, and holes with utmost accuracy.view 3-Axis Vs 4-Axis Vs 5-Axis CNCJuly 21, 20233-axis machiningThree axis CNC machining is the most basic, commonly used in the machinery manufacturing industry is one of the most important processing methods. Common understanding is: accurate lin...view

3-Axis Vs 4-Axis Vs 5-Axis CNCJuly 21, 20233-axis machiningThree axis CNC machining is the most basic, commonly used in the machinery manufacturing industry is one of the most important processing methods. Common understanding is: accurate lin...view CNC Piston Machining: Crafting High-Quality Engine ComponentsNovember 7, 2023Are you in pursuit of engine components that combine precision, reliability, and performance? Your quest for top-notch CNC piston machining ends here. In this comprehensive guide, I will take you on a journey through the intricacies of CNC piston machining, shedding light on the processes, technologies, and services that define this critical aspect of engine manufacturing.view

CNC Piston Machining: Crafting High-Quality Engine ComponentsNovember 7, 2023Are you in pursuit of engine components that combine precision, reliability, and performance? Your quest for top-notch CNC piston machining ends here. In this comprehensive guide, I will take you on a journey through the intricacies of CNC piston machining, shedding light on the processes, technologies, and services that define this critical aspect of engine manufacturing.view Flexible CNC Lead Times - Save Money with Longer Lead TimesOctober 12, 2023From now on, you have the flexibility to choose your CNC delivery times and thus determine your own delivery dates and costs for your CNC parts. As part of the Flexible Manufacturing option, our lead times of 6 to 12 days offer you a lower price - and you'll still receive your parts faster than most other suppliers.view

Flexible CNC Lead Times - Save Money with Longer Lead TimesOctober 12, 2023From now on, you have the flexibility to choose your CNC delivery times and thus determine your own delivery dates and costs for your CNC parts. As part of the Flexible Manufacturing option, our lead times of 6 to 12 days offer you a lower price - and you'll still receive your parts faster than most other suppliers.view Material Comparison: Difference between High Speed Steel and Tungsten SteelOctober 31, 2023Materials play a vital role in modern industry, and in the field of precision manufacturing, both high-speed steel and tungsten steel are highly regarded materials. They have an important position in the field of tool, mold and mechanical parts manufacturing, etc. However, there are obvious differences between them in terms of characteristics, features, application areas, etc. In this article, we will introduce and compare them. This article will be introduced and compared.view

Material Comparison: Difference between High Speed Steel and Tungsten SteelOctober 31, 2023Materials play a vital role in modern industry, and in the field of precision manufacturing, both high-speed steel and tungsten steel are highly regarded materials. They have an important position in the field of tool, mold and mechanical parts manufacturing, etc. However, there are obvious differences between them in terms of characteristics, features, application areas, etc. In this article, we will introduce and compare them. This article will be introduced and compared.view Sheet Metal Bending: Comprehensive Insights from Processes to EconomicsJuly 25, 2024Sheet metal bending holds a significant place in manufacturing. Let’s discover its diverse processes, unique methods, safety aspects, and cost analysis in this comprehensive exploration.view

Sheet Metal Bending: Comprehensive Insights from Processes to EconomicsJuly 25, 2024Sheet metal bending holds a significant place in manufacturing. Let’s discover its diverse processes, unique methods, safety aspects, and cost analysis in this comprehensive exploration.view