With the increasing number of types of CNC lathes, the names of many lathes gradually become difficult to understand. Next, let's understand what is CNC turning-milling compound. Before we understand CNC turning-milling center compounding, we must first understand CNC lathe and CNC milling machine to see what kind of difference they have.

Precision CNC lathe refers to a machine tool that mainly uses CNC lathe tools to turn rotating workpieces. Generally, it means that the tool of the lathe is fixed at a specific position on the machine tool, and the workpiece rotates along the axis under the clamping of the fixture, and is cut when it approaches the knife edge. Therefore, it is mainly suitable for machining shafts, discs, sleeves and other workpieces with reversed surfaces. It is the most widely used type of machine tool in machinery manufacturing and repair factories. Common CNC milling machines and drilling machines and other rotary processing machines are derived from precision CNC lathes. Its processing principle is that the workpiece is rotating and the tool is fixed.

Precision CNC milling machine refers to a machine tool that mainly uses milling cutters to process various surfaces on the workpiece. The performance of the precision CNC milling machine is that the rotary motion of the milling cutter is the main motion, and the workpiece and the milling cutter can move as the feed motion. That is to say, its object is fixed at a certain position of the machine tool, and the milling cutter rotates at a high speed under the clamping of the fixture. When touching the workpiece, it can process planes and grooves on its surface, and can also process various curved surfaces, gears and other CNC milling machines. It is a machine that uses a milling cutter to mill a workpiece. It can process planes, grooves, toothed parts, helical surfaces and various curved surfaces on a CNC milling machine. In addition, it can also be used to process the surface of the inverting body, the inner hole and the blocking operation. Due to the multi-tool intermittent cutting, the productivity of the CNC milling machine is high. The processing principle of the CNC milling machine is that the workpiece is fixed and the tool is rotating.

CNC turning and milling center compound, as the name suggests, is a compound machine tool that includes all the functional characteristics of CNC lathes and CNC milling machines. Its functions include turning milling compounding, turning milling compounding, milling and milling compounding. The machine tool has multiple functions. It can complete multiple tasks in one clamping, improve processing efficiency and processing accuracy, because it combines the characteristics of several CNC lathes into one machine, which greatly reduces the floor space and rent. and other capital costs. Although the unit price of CNC turning and milling is relatively high, because it can shorten the manufacturing process chain and the number of fixtures, workshop area and reduce equipment maintenance costs, it can also effectively reduce the overall investment in fixed assets from the perspective of enterprise investment, greatly reducing the cost of production operation and management of personnel and equipment.

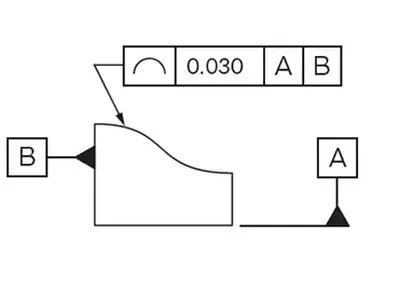

Unveiling the Precision: The Line Profile UnraveledNovember 21, 2023In the vast realm of engineering and manufacturing, the significance of line profiles cannot be overstated. These seemingly simple geometric elements play a pivotal role in ensuring precision, guiding us through the intricacies of design and production.view

Unveiling the Precision: The Line Profile UnraveledNovember 21, 2023In the vast realm of engineering and manufacturing, the significance of line profiles cannot be overstated. These seemingly simple geometric elements play a pivotal role in ensuring precision, guiding us through the intricacies of design and production.view The Top 7 CAD/CAM Software for CNC ProjectsMarch 18, 2024CAD/CAM software for CNC projects is a specialized tool used to design and control the machining of parts. Here are the top 7 CAD/CAM software for your choice.view

The Top 7 CAD/CAM Software for CNC ProjectsMarch 18, 2024CAD/CAM software for CNC projects is a specialized tool used to design and control the machining of parts. Here are the top 7 CAD/CAM software for your choice.view The Role of CNC Machining in the Automotive IndustryApril 25, 2023CNC machining is commonly used for complex designs, small products, and parts. Through CNC machine tools, a variety of parts can be machined more accurately.With the rapid development of the automotiv...view

The Role of CNC Machining in the Automotive IndustryApril 25, 2023CNC machining is commonly used for complex designs, small products, and parts. Through CNC machine tools, a variety of parts can be machined more accurately.With the rapid development of the automotiv...view 5 Important Facts About 5 Axis Machining | Basics Information, Benefits, Limitations, Applications & TipsFebruary 20, 20245 axis CNC machining technology is important in manufacturing. Learn more about its basics, pros &cons, applications, and tips to enhance your project performance.view

5 Important Facts About 5 Axis Machining | Basics Information, Benefits, Limitations, Applications & TipsFebruary 20, 20245 axis CNC machining technology is important in manufacturing. Learn more about its basics, pros &cons, applications, and tips to enhance your project performance.view The Complete Guide to CNC Machining ServiceMay 31, 2024What is CNC machining service? What are advantages of CNC Machining Service? How to find a reliable CNC Machining Service? Let’s find the answers with the help of this article!view

The Complete Guide to CNC Machining ServiceMay 31, 2024What is CNC machining service? What are advantages of CNC Machining Service? How to find a reliable CNC Machining Service? Let’s find the answers with the help of this article!view 7 Tips for Choosing a Right CNC Machine ManufacturerSeptember 7, 2023Some companies seek a quality precision manufacturer with the best matching services. Nowadays, there are lots of CNC manufacturers to choose from. The problem is how to pick out the right CNC manufac...view

7 Tips for Choosing a Right CNC Machine ManufacturerSeptember 7, 2023Some companies seek a quality precision manufacturer with the best matching services. Nowadays, there are lots of CNC manufacturers to choose from. The problem is how to pick out the right CNC manufac...view

EN

EN

ru

ru