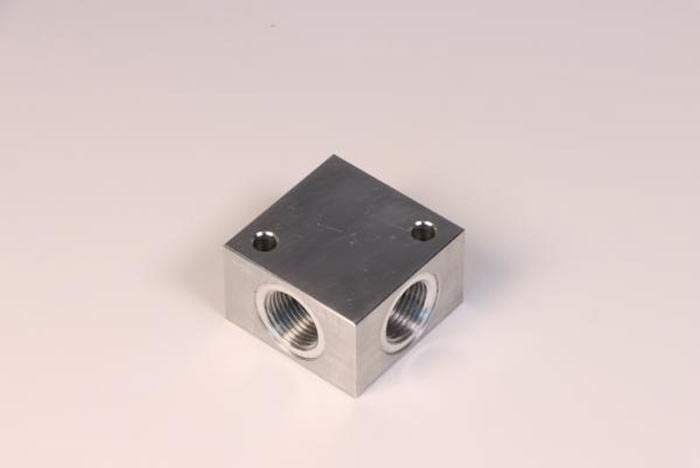

The aerospace fastener is an essential part of aerospace equipment which is the core product of modern aviation industry. The main function of air fasteners is to ensure the safety and stability of aircraft during flight, so its quality and reliability are of great importance. With the continuous development of the aviation industry and the continuous upgrading of aircraft, the demand for aircraft fasteners will be more high-end, diversified and personalized. Now, let’s learn more details about aerospace fasteners, including their types, features, materials, etc.

Aerospace fasteners are types of hardware used to attach parts and components in the aerospace industry. They play an important role in the manufacture and maintenance of aircraft structures. They are typically made of metal alloys such as steel, aluminum, titanium, and nickel-based alloys, and they come in various shapes and sizes. Aerospace fasteners are designed to withstand extreme temperatures, high pressures, and harsh environments.

There are some common types of aerospace fasteners including bolts, screws, nuts, rivets, pins, and clips. They are widely used in the connection and fixation of aircraft wings, fuselage, landing gear, engines, doors and other parts. Besides, air fasteners are essential components in aerospace engineering, and they must meet strict standards for strength, reliability, and safety. For example, they must be created with high durability and first-class quality.

Aerospace fasteners, as an indispensable part of aviation manufacturing, play an important role in connecting, fixing and protecting various parts of aircraft. Their characteristics and attributes determine the safety and reliability of the whole aircraft. Here we will give you a detailed introduction to the characteristics of aircraft fasteners to help you better understand the aviation manufacturing industry.

High Strength

Aerospace fasteners must be strong enough to withstand the rigors of extreme conditions, such as high speed, high temperature, high pressure and vibration.

Corrosion Resistance

Aerospace fasteners must be able to resist corrosion caused by exposure to extreme temperatures, humidity, and other environmental contaminants.

Lightweight

Aerospace fasteners must be lightweight in order to minimize the overall weight of the aircraft.

Non-Magnetic

Aerospace fasteners must be non-magnetic to prevent interference with the aircraft’s navigation and communication systems.

Low Friction

Aerospace fasteners must be able to resist friction caused by high speed and vibration.

Aerospace fasteners are an integral part of the aerospace industry, and they are available in a variety of sizes, thread types, and drive styles to meet the needs of any aerospace application. Here are some common fasteners examples including bolts, screws, studs, nuts and rivets.

Bolts: Bolts are the most common type of fastener used in aerospace applications. They are defined as a type of threaded fastener that requires a pre-drilled hole and a nut to secure two or more components together. Bolts are usually made of corrosion-resistant materials such as steel or aluminum alloys.

Nuts: Nuts are a type of threaded fastener that is typically used in conjunction with a bolt to secure two or more components together. Non-locking and self-locking airplane nuts are available. They are indispensable for aircraft that need to go through plenty of vibrations.

Rivets: Rivets are a type of fastener used to join two or more components together. They are typically made from aluminum or other metals and are inserted into pre-drilled holes and then formed or deformed to secure the components together.

Screws: The majority of fasteners used in aircraft structures are screws which also have exterior threads just like bolts, but they have a helical ridge. They are frequently constructed of lower-strength materials than bolts and inserted with a loose-fitting thread. In the construction of aircraft, many types of screws with various materials and designs are employed.

Studs: Studs are a type of fastener used to secure two components together in a single direction. They are typically used in applications where a component needs to be secured in a single direction, such as a propeller shaft or a rudder.

Besides, there are some special air fasteners examples.

Lockbolts: Lockbolts are a type of fastener that uses a two-piece assembly to secure two or more components together. The fastener consists of a threaded bolt and a pin that is inserted into a pre-drilled hole.

Blind Fasteners: Blind fasteners are used to join two or more components together in a non-visible manner. They are typically used in applications where access to the backside of the components is not possible.

Aerospace fasteners are typically made from a variety of materials, including aluminum, steel, titanium, bronze, nickel-based alloys, and so on. Each material has its own unique set of properties that make it suitable for different applications.

Aluminum is lightweight, strong, and corrosion-resistant. It is often used in aerospace components due to its strength-to-weight ratio and resistance to fatigue, making it ideal for the fuselage.

Steel

Steel is strong and durable, making it a popular choice for engines and other components that require a high level of strength. It is also highly resistant to corrosion and temperature extremes.

Titanium

Titanium is a lightweight and strong metal that is highly resistant to corrosion. Aluminum could be replaced with Titanium for making various fasteners for commercial airplanes. In terms of strength, the strength of titanium is not inferior to that of steel.

Superalloys

Superalloys are a class of materials that are typically used in high-temperature applications due to their excellent strength and corrosion resistance. They are made up of a combination of metals such as nickel, cobalt, and iron, and often include other elements like chromium, molybdenum, and tungsten. Superalloys are typically used in extreme industrial applications, such as jet engines, nuclear reactors, and oil and gas exploration. They are also used in medical devices and aerospace components. Superalloys have a wide range of applications due to their ability to withstand high temperatures and extreme conditions.

Aviation quality standards refer to a set of regulations and procedures followed by the aviation industry to ensure the safety, reliability, and efficiency of aircraft and other aviation-related operations. Examples of aviation quality standards are as follows:

AS9100 and AS9120 standards: are widely used in the aviation industry.

AS9100, BA9100 and EN9100 standards: are followed by organizations creating and producing aerospace products, such as parts, components, and assemblies.

AS9120, BS9120, and EN9120 standards: are for people who produce or sell aviation parts, components, etc.

The covers of fasteners are definitely needed to resist the harsh environmental conditions.The materials used to make those covers come in a wide range and have varying degrees of resistance to the various environmental situations encountered. Here are the materials used for aircraft fastener covers:

Zinc

Nickel

Cadmium

Silver

Black Oxide

Phosphate

Aviation fasteners are closely related to CNC machining and Richconn does an excellent job in OEM CNC machining of aerospace parts. Are you looking for a reliable partner for your project of aerospace fasteners? Richconn, a company with professional team, many years of experience and excellent technology, is definitely a good choice. Don't hesitate to contact us and you will get good service a reasonable price, and most importantly, high quality!

As an important part of aerospace equipment, the quality and reliability of aircraft fasteners play an important role in the safety and stability of aircraft. They fasten a variety of parts of the plane together to make it work properly. We introduce many aspects of aerospace fasteners, including characteristics, types, materials, and so on. Choose your ideal partner now!

The Difference Between Precision Sheet Metal Fabrication and Ordinary Sheet Metal FabricationSeptember 27, 2023In recent years, as the market demand for precision of sheet metal parts has increased, precision sheet metal fabrication has also begun to enter the center stage of the sheet metal industry.view

The Difference Between Precision Sheet Metal Fabrication and Ordinary Sheet Metal FabricationSeptember 27, 2023In recent years, as the market demand for precision of sheet metal parts has increased, precision sheet metal fabrication has also begun to enter the center stage of the sheet metal industry.view CNC Plastics Selection Guide | Machining MaterialsJune 18, 2024Delve into the realm of engineering plastics to discover a wide range of materials, their unique characteristics, and diverse processing techniques.view

CNC Plastics Selection Guide | Machining MaterialsJune 18, 2024Delve into the realm of engineering plastics to discover a wide range of materials, their unique characteristics, and diverse processing techniques.view The Benefits of Anodizing Precision Machined Aluminum ProductsOctober 19, 2023Why might you want to anodize aluminum? There are several good reasons to consider anodizing aluminum parts. Anodizing aluminum creates a layer of oxide and forms a layer on the surface of the aluminum.view

The Benefits of Anodizing Precision Machined Aluminum ProductsOctober 19, 2023Why might you want to anodize aluminum? There are several good reasons to consider anodizing aluminum parts. Anodizing aluminum creates a layer of oxide and forms a layer on the surface of the aluminum.view Do You Know How Anodizing Works?November 4, 2022Anodizing, the process of forming an oxide film on aluminum products (anode) under the action of an applied current under the corresponding electrolyte and specific process conditions of metal or allo...view

Do You Know How Anodizing Works?November 4, 2022Anodizing, the process of forming an oxide film on aluminum products (anode) under the action of an applied current under the corresponding electrolyte and specific process conditions of metal or allo...view Ultra-High Precision Laser Cutting Technology: A Detailed Explanation of Its Technology and ApplicationsJanuary 3, 2024We delve into the intricacies of ultra-high-precision laser cutting, exploring its technology, applications, benefits and challenges.view

Ultra-High Precision Laser Cutting Technology: A Detailed Explanation of Its Technology and ApplicationsJanuary 3, 2024We delve into the intricacies of ultra-high-precision laser cutting, exploring its technology, applications, benefits and challenges.view What Will Determine the Precision of CNC Machining?August 10, 2022In the preparation of CNC machining programs, proper use of methods and techniques is of great significance to ensure and improve the machining accuracy of CNC machine tools. So what determines the ma...view

What Will Determine the Precision of CNC Machining?August 10, 2022In the preparation of CNC machining programs, proper use of methods and techniques is of great significance to ensure and improve the machining accuracy of CNC machine tools. So what determines the ma...view

EN

EN

ru

ru