When it comes to surface treatments for various metal components, one often thinks about aesthetics and corrosion resistance as the primary goals. However, there is another important surface treatment that goes beyond just visual appeal and offers numerous practical benefits – blackening surface treatment. In this article, we will delve into the practical advantages of blackening surface treatment and why it should be considered as an essential part of metal finishing processes.

Blackening surface treatment significantly enhances the durability and wear resistance of metal components. By creating a black oxide layer on the surface of the metal, the treated part becomes less susceptible to scratches, abrasions, and general wear and tear. This is particularly advantageous for components exposed to harsh environments or frequent usage, such as automotive parts or industrial equipment. Blackening surface treatment extends the lifespan of these components, reducing the need for frequent replacements and increasing overall cost-effectiveness.

While corrosion resistance is often associated with traditional surface treatments like chrome plating or galvanizing, blackening surface treatment offers a unique advantage in this regard. The black oxide layer formed during the blackening process acts as a protective barrier against corrosion, effectively preventing rust and other forms of oxidation. This is especially valuable in industries such as marine, oil and gas, or outdoor equipment manufacturing, where exposure to moisture and corrosive elements is frequent. Blackening surface treatment ensures the integrity and longevity of metal components, even in the harshest of environments.

Blackening surface treatment improves the lubricity and anti-galling properties of metal components, particularly those subject to friction or sliding motions. The black oxide layer acts as a solid lubricant, reducing friction between moving parts and minimizing the risk of galling. This is crucial in applications involving sliding mechanisms, such as gears, shafts, or sliding bearings. Blackening surface treatment not only enhances the overall performance and efficiency of these components but also reduces the need for additional lubrication, leading to potential cost savings and improved maintenance processes.

While the primary focus of this article is the practical benefits of blackening surface treatment, it is worth mentioning the aesthetic appeal and stealth capabilities it brings to certain applications. The black color achieved through blackening surface treatment provides a visually appealing finish, often preferred in industries such as firearms, automotive, or high-end consumer goods. Additionally, the dark and matte appearance of the blackened surface offers increased camouflage and stealth capabilities, making it ideal for sensitive applications where minimizing visibility is crucial.

Blackening surface treatment offers far more than just visual appeal. Its practical benefits, including enhanced durability, improved corrosion protection, enhanced lubricity, and even stealth capabilities, make it an essential part of metal finishing processes. Whether in industries requiring robust components, such as automotive or oil and gas, or those focused on aesthetics and discretion like firearms, blackening surface treatment plays a vital role in optimizing performance, extending component lifespan, and reducing maintenance costs. With its multitude of advantages, blackening surface treatment should not be overlooked in any metal finishing process.

![Examining Alloy Definition and Alloying Examples [Basic Guide]](/uploads/image/20240226/14/basic-guide_400x400.webp) Examining Alloy Definition and Alloying Examples [Basic Guide]February 26, 2024Learn from alloy definitions and alloying examples, which can help you choose the best alloy for your project.view

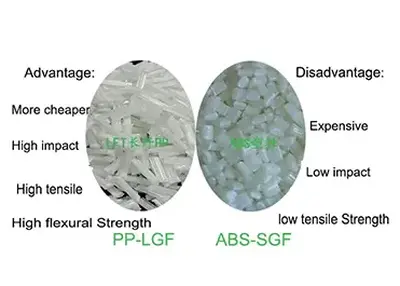

Examining Alloy Definition and Alloying Examples [Basic Guide]February 26, 2024Learn from alloy definitions and alloying examples, which can help you choose the best alloy for your project.view ABS vs. Polypropylene (PP): A Comparison of Two Common PlasticsNovember 28, 2023Plastics are widely used materials in various industries, such as packaging, automotive, medical, and consumer products. Plastics are synthetic or semi-synthetic polymers that can be molded or shaped into different forms and products. There are many types and grades of plastics, each with different chemical compositions and physical properties.view

ABS vs. Polypropylene (PP): A Comparison of Two Common PlasticsNovember 28, 2023Plastics are widely used materials in various industries, such as packaging, automotive, medical, and consumer products. Plastics are synthetic or semi-synthetic polymers that can be molded or shaped into different forms and products. There are many types and grades of plastics, each with different chemical compositions and physical properties.view Can Titanium Be Machined: Comprehensive analysis of CNC machining of titanium materialsNovember 10, 2023Greetings, machining enthusiasts! Have you ever wondered if titanium, that resilient and lightweight metal, can truly be harnessed through CNC machining? I'm here to not only answer your burning question but to delve into the intricacies, challenges, and best practices associated with machining titanium. As Richconn, your go-to precision machine shop, let's unlock the full potential of this extraordinary material together.view

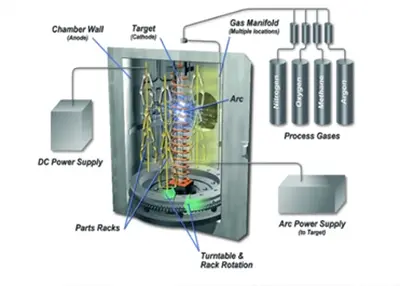

Can Titanium Be Machined: Comprehensive analysis of CNC machining of titanium materialsNovember 10, 2023Greetings, machining enthusiasts! Have you ever wondered if titanium, that resilient and lightweight metal, can truly be harnessed through CNC machining? I'm here to not only answer your burning question but to delve into the intricacies, challenges, and best practices associated with machining titanium. As Richconn, your go-to precision machine shop, let's unlock the full potential of this extraordinary material together.view Explain 5 Common Electroplating ProcessesOctober 24, 2022In mechanical design, electroplating is one of our most common surface treatment processes for parts. Today we will take a look at 5 commonly used electroplating processes. There are many methods of e...view

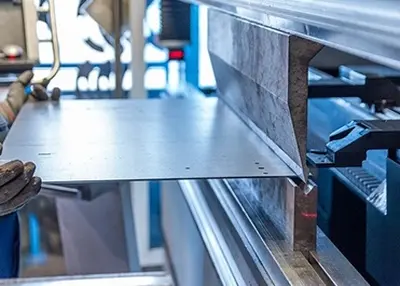

Explain 5 Common Electroplating ProcessesOctober 24, 2022In mechanical design, electroplating is one of our most common surface treatment processes for parts. Today we will take a look at 5 commonly used electroplating processes. There are many methods of e...view 5 Bending and Forming Methods for Sheet MetalDecember 4, 2023Sheet metal refers to a process used to manufacture a variety of metal products, which involves processing sheet metal into the desired shape and size by cutting, stamping, bending, and welding.view

5 Bending and Forming Methods for Sheet MetalDecember 4, 2023Sheet metal refers to a process used to manufacture a variety of metal products, which involves processing sheet metal into the desired shape and size by cutting, stamping, bending, and welding.view Rivets: 25 Types Of Introduction And User GuideSeptember 26, 2023Rivets are parts that join multiple components and structures together to form a complete body. These parts can be manipulated with some specialized tools. One of the panaceas of manufacturing is rivets. Depending on their design requirements and performance, different types of rivets can be used.view

Rivets: 25 Types Of Introduction And User GuideSeptember 26, 2023Rivets are parts that join multiple components and structures together to form a complete body. These parts can be manipulated with some specialized tools. One of the panaceas of manufacturing is rivets. Depending on their design requirements and performance, different types of rivets can be used.view

EN

EN

ru

ru