Metal is a basic part of industries such as manufacturing due to its strength, durability, and ability to retain sheen over an extended time. Among the several types of metal available in the market, cast iron vs steel is one of the many comparisons common among manufacturers who want to work with metal.

Selecting any of the two types of steel should only occur after understanding the properties of the project. Is cast iron stronger than steel? How is steel made from iron? This article breaks down everything you need to know about the difference between cast iron and steel. So, you can choose any of them for your project.

Cast iron is produced through smelting iron-carbon alloys with a carbon content typically ranging between 2-4%. To clarify, cast iron contains a higher carbon content exceeding 2%. Instead of hammering and using tools, the molten iron is poured into a mold after the smelting process.

In addition to carbon, iron also contains 1-3% silicon, enhancing its casting performance. Traces of manganese may be present, and impurities like phosphorus and sulfur can also be found. Iron exhibits various mechanical properties such as hardness, elasticity, ductility, and toughness. This metal alloy is obtained by reducing iron ore in a blast furnace. Its composition includes varying proportions of silicon and manganese, along with small amounts of impurities such as sulfur and phosphorus.

Different types of this brittle material exist, resulting from various processing techniques and heat treatments employed during production. The various types of cast iron comprise:

Gray Iron

White Iron

Malleable Iron

Ductile Iron

Compacted Graphite Iron

Is steel made of iron? Steel is an alloy of iron and carbon in which the carbon content ranges up to 2 percent (with a higher carbon content, the material is defined as cast iron). The presence of carbon in steel contributes to its increased strength and resistance to breakage. Additionally, steel can be alloyed with other elements such as silicon, manganese, phosphorus, sulfur, and oxygen to enhance its properties. For example, stainless steel, which is resistant to oxidation and corrosion, often contains 11% chromium.

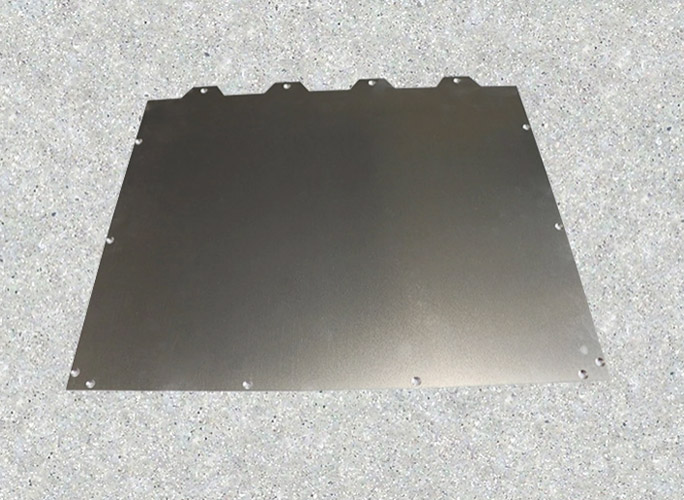

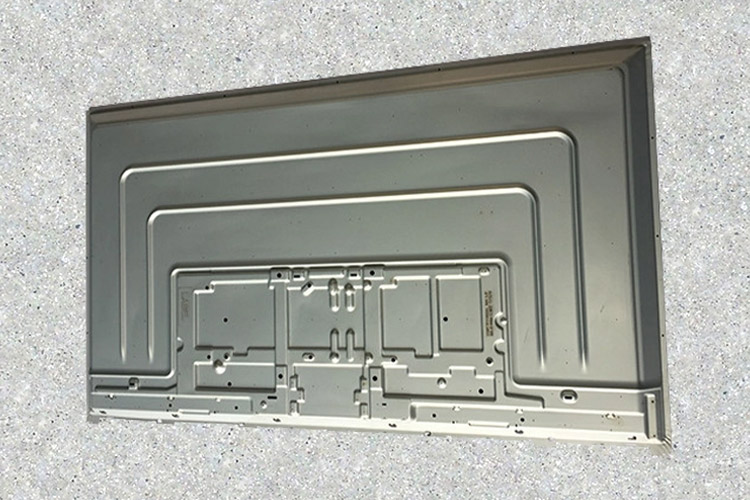

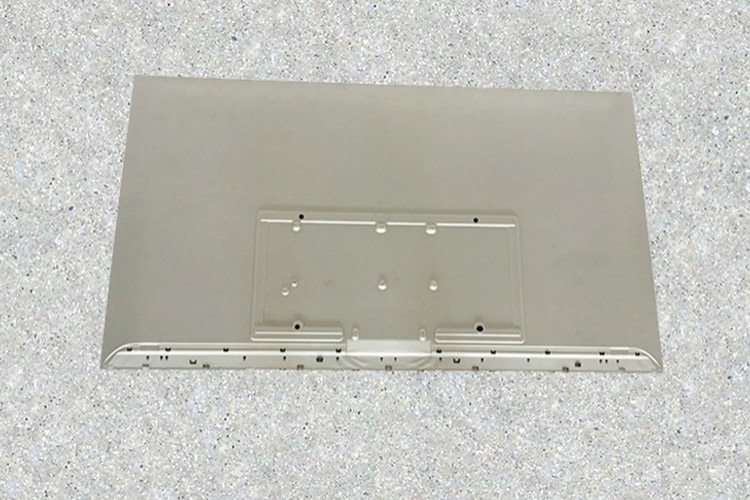

With its high tensile strength, steel has numerous applications in manufacturing tools, vehicles, machinery, weapons, and infrastructure construction. It is also utilized in the fabrication of steel guides for customized prototyping purposes.

The various types of iron comprise:

Stainless Steel

Tool Steel

Are cast iron and iron steel the same? They only have a similar appearance. In contrast, there are many cast iron and steel differences. You may ask the questions. Is steel stronger than cast iron? Or is cast iron stronger than steel? Let’s examine the difference between them and give you have clear idea of which is stronger: cast iron or steel.

Attribute | Cast Iron | Steel |

Composition | High carbon content, with 2-4% carbon | Steel made from iron (called iron steel), and with other elements |

Strength | Brittle and exhibiting low tensile strength | Resilient and possessing high tensile strength |

Hardness | Hard and brittle | Varies based on the specific type |

Malleability | Less Malleable | Malleable, capable of being molded and shaped. |

Ductility | Less ductile | Ductile, and capable of being Stretched Without Fracturing |

Cost | More cost-effective to produce due to its lower material cost, reduced labor requirements, and lower energy consumption during the production process | More expensive than cast iron, despite the presence of cheaper alternatives such as prefabricated steel forms like rods, bars, beams, and tubes |

Application | Construction, automotive manufacturing, machinery and equipment, appliances, tools, and infrastructure development | Aerospace, shipbuilding, energy production, machinery and equipment manufacturing, weapons and defense, electrical appliances |

Strength

For strength, which is stronger, cast iron or steel? Cast iron generally possesses more strength compared to steel. Conversely, steel exhibits greater tensile strength, allowing it to bend without breaking. To clarify, the high compressive strength of iron makes it highly resistant to dents and bending, but it is prone to breaking under excessive pressure.

Castability

Iron is easier to cast than steel due to its higher flowability and minimal shrinkage. In contrast, steel has a lower fluidity, reacts with the mold material, and contracts as it cools. Steel also has a relatively high viscosity. The superior castability of iron makes it suitable for intricate ironwork structures.

Corrosion Resistance

Is steel and cast iron the same in corrosion resistance? Cast iron possesses better resistance to corrosion and rust compared to steel. However, it's important to note that neither material is completely immune to corrosion. If exposed and unprotected, both cast iron and steel will undergo oxidation, leading to decomposition.

Impact Resistance

Is iron or steel stronger? Steel exhibits superior impact resistance compared to iron, especially when it comes to sudden impacts. Steel is less prone to bending, breaking, or deforming quickly under these circumstances.

Cost

Is cast iron the same as steel? Cast iron is generally less expensive than steel due to the lower cost of materials required for its production. Additionally, the production of raw steel involves more labor and energy consumption.

Applications

Both materials find applications in different fields. Cast iron is commonly used in the manufacturing of pipe fittings, washers, farm equipment, machine parts, mining hardware, electrical fittings, and hand tools. Conversely, steel is well-suited for the production of tools, weapons, electrical appliances, vehicles, and infrastructure.

Before you choose the right material, you should know their respective advantages and disadvantages.

High compressive strength: Cast iron exhibits excellent strength when subjected to compressive forces.

Castability: Cast iron has lower melting and casting temperatures, better flowability, and reduced shrinkage compared to steel. This makes it cheaper and easier to cast.

Machinability: Softer types of iron, like gray iron, are easy to machine quickly and accurately.

Hardness: Cast iron possesses high hardness compared to other low-cost metals.

Cost efficiency: Cast iron offers a variety of advantageous properties at a relatively low cost.

Susceptibility to corrosion: Cast iron is prone to rust and corrosion when exposed to moisture and oxygen.

Brittle behavior: This iron can be prone to brittleness, making it less suitable for applications requiring high impact resistance.

Lower tensile strength: Cast iron typically has lower tensile strength compared to materials like steel.

Limited malleability: Cast iron is not as malleable as some other metals, which can limit its ability to be shaped and formed.

High tensile strength: Steel, depending on the alloy used, can possess significantly higher tensile strength compared to iron.

Toughness and ductility: Steel can deform under high stress without breaking, making it more resistant to cracking and offering better impact performance.

Weldability: Steel generally offers good weldability, making it easier to join and fabricate using welding techniques compared to cast iron, which is challenging to weld without causing cracks.

Higher cost: Steel is generally more expensive than other materials, such as cast iron.

Susceptibility to corrosion: Steel is prone to rust and corrosion, especially when exposed to moisture and certain environments.

Deciding between cast iron and steel can be challenging. It boils down to the nature of your project and the investment you’re ready to make. At Richconn, we simplify this choice for you.

Versatility for Any Project: Regardless of the simplicity or complexity of your parts, and whether you need them in small or large quantities, our expertise can accommodate all your requirements.

Efficient Ordering: Enjoy a quick and simplified ordering process with instant quotes and the added benefit of our complimentary analysis when you upload your design files.

Expert Recommendations: Our knowledgeable engineers will carefully review your designs and provide expert recommendations on the most efficient sheet metal process. This personalized approach helps you save time and minimize costs.

Cast iron and steel are both valuable construction materials, each possessing distinct characteristics. This type of iron stands out for its exceptional compression strength and heat resistance, while steel offers superior tensile strength, machinability, and corrosion resistance. The choice between cast iron and steel depends on factors such as the specific requirements of the application, budget, and desired properties. By comprehending the similarities and differences between these materials, engineers and manufacturers can make educated decisions and choose the most suitable material for their projects.

Alloy Steel vs Carbon Steel: Which Is Better?September 5, 2023Steel is a major global industry that involves the combination of iron with other elements, both metallic and non-metallic, to create a versatile material. This combination is done to attain specific ...view

Alloy Steel vs Carbon Steel: Which Is Better?September 5, 2023Steel is a major global industry that involves the combination of iron with other elements, both metallic and non-metallic, to create a versatile material. This combination is done to attain specific ...view Introduction to CNC MachiningNovember 23, 2023Boring is a very widely used process that involves drilling, reaming, boring, reaming and internal surface broaching tools. Compared to other machining, boring is a difficult process.view

Introduction to CNC MachiningNovember 23, 2023Boring is a very widely used process that involves drilling, reaming, boring, reaming and internal surface broaching tools. Compared to other machining, boring is a difficult process.view Richconn: Secondary ServicesOctober 12, 2023Many of our customers order parts that come ready-made from plastic injection molding or CNC machining. Many others, however, want or need "secondary machining" of the parts so produced.view

Richconn: Secondary ServicesOctober 12, 2023Many of our customers order parts that come ready-made from plastic injection molding or CNC machining. Many others, however, want or need "secondary machining" of the parts so produced.view What Is CNC Cutting? Unlocking the World of Precision MachiningNovember 2, 2023Are you intrigued by the world of precision manufacturing and curious about the fascinating technology behind it? If so, you've come to the right place. In this comprehensive guide, I'll take you on a journey through the realm of CNC Cutting, revealing its inner workings, diverse applications, and future trends.view

What Is CNC Cutting? Unlocking the World of Precision MachiningNovember 2, 2023Are you intrigued by the world of precision manufacturing and curious about the fascinating technology behind it? If so, you've come to the right place. In this comprehensive guide, I'll take you on a journey through the realm of CNC Cutting, revealing its inner workings, diverse applications, and future trends.view Some Knowledge You Need to Learn About Tapped HoleNovember 16, 2023Do you need taped holes? This article covers the factors you must consider to manufacture the tapped hole during the process.view

Some Knowledge You Need to Learn About Tapped HoleNovember 16, 2023Do you need taped holes? This article covers the factors you must consider to manufacture the tapped hole during the process.view 2024 China (Shenzhen) International Industrial Parts Exhibition (CIIPES-2024)January 3, 2024Exhibition OverviewIn order to further enhance the development of the industrial parts industry, fully display the cutting-edge equipment technology of the industrial parts industry, actively promote ...view

2024 China (Shenzhen) International Industrial Parts Exhibition (CIIPES-2024)January 3, 2024Exhibition OverviewIn order to further enhance the development of the industrial parts industry, fully display the cutting-edge equipment technology of the industrial parts industry, actively promote ...view

EN

EN

ru

ru