The cost of a CNC (Computer Numerical Control) machine can vary widely depending on several factors, including the type of machine, its size, capabilities, brand, and whether it's new or used.

Here are some general price ranges for different types of CNC machines:

Benchtop CNC machines: These are small, compact CNC machines for hobbyists and small projects. They range in price from a few hundred to a few thousand dollars.

Entry-level CNC mills and milling machines: these machines are larger than the benchtop models and can handle larger projects. They typically cost between $5,000 and $20,000.

Mid-range CNC machines: These machines are more powerful and accurate and are suitable for small to medium-sized businesses. Prices typically range from $20,000 to $100,000.

High-end CNC machines: Industrial-grade CNC machines designed for mass production or highly specialized tasks can cost hundreds of thousands to millions of dollars.

Used CNC machines: You can often find used CNC machines at a fraction of the cost of new machines. Prices for used machines vary widely depending on age, condition and features.

Custom CNC Machines: Some companies choose to customize their CNC machines to their specifications. The cost of a customized CNC machine will depend on the complexity of the design and the features you need.

It is important to note that in addition to the upfront cost of the machine, you should also consider other costs such as software, tooling, maintenance and training. CNC machines also have ongoing operating costs, including electricity and tool replacement.

If your demand is small, your utilization rate is low, or you don't want to invest a large amount of money in CNC machine tools, then it is a wise choice to look for a professional CNC machining service provider.CNC machining service companies usually have state-of-the-art CNC machine tools and experienced operation teams, which can provide you with the following advantages:

Cost-effectiveness: There is no need to purchase and maintain CNC machines, avoiding large capital expenditures and maintenance costs.

Flexibility: You can order CNC machining services whenever you need them, without worrying about idle or obsolete machines.

Expertise: CNC machining service providers usually have the expertise and experience to ensure high-quality machining and accurate workpiece fabrication.

Material options: They can offer a variety of different material options to meet your specific needs, whether it's metal, plastic, composite, or other materials.

Machining capabilities: CNC machining service companies typically have a wide range of machining capabilities, including milling, turning, drilling, grinding, and more, to accommodate a variety of workpiece types and requirements.

Lead time: They can provide fast delivery according to your schedule, helping you meet project deadlines.

Quality control: CNC machining service providers usually have a quality control system in place to ensure that products meet specifications and standards.

Richonn is a professional CNC machining service provider that offers customized CNC machining solutions that can meet your specific needs. If you need CNC machining services, you can contact them for more information and a quote.

Cheap CNC machines are attractive due to their low upfront cost, but whether they are worth it depends on your specific needs, expectations, and how you plan to use the machine.

Hobbyists and learning: If you are a beginner or hobbyist looking to learn CNC machining or work on small personal projects, then a cheap CNC machine may be suitable.

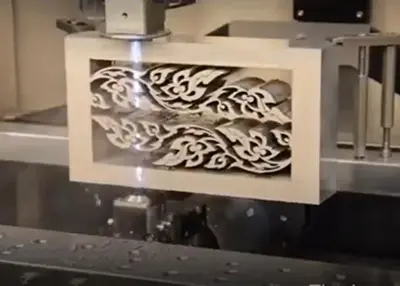

Light tasks: an inexpensive CNC machine may be adequate for light tasks such as carving, basic woodworking or simple prototyping.

ACCURACY AND PRECISION: Inexpensive CNC machines often have limitations in terms of accuracy and precision. They may not be suitable for projects that require tight tolerances or high precision.

Materials: Some inexpensive CNC machines may have difficulty with harder materials such as metal. They are often better suited to softer materials such as plastics and wood.

Durability: Low-cost machines may not be as durable as more expensive models and wear out faster with frequent use.

3. Support and maintenance:

Customer support: consider the level of customer support and documentation available for the machine. Less expensive machines may not have robust support options.

Maintenance: Be prepared for potential maintenance and repairs. Cheaper machines may require more frequent maintenance and parts replacement.

Limited upgradeability: cheaper CNC machines may have limited upgrade or customization options, which may limit their long-term utility.

Hidden costs: While the initial purchase price may be low, there are still additional costs to consider, such as tooling, software, and any necessary upgrades or repairs.

Assembly and calibration: some inexpensive CNC machines may require extensive assembly and calibration, which can be very time consuming and may require technical expertise.

For some users and applications, inexpensive CNC machines can be worthwhile, especially for beginners, hobbyists, or those with limited budgets but moderate requirements. However, it is important to have realistic expectations of their capabilities and limitations. If you have more demanding or long-term needs, then investing in a higher quality CNC machine with better features, precision and support may ultimately provide better value and save you time and frustration in the long run. Consider your specific use case, budget and goals when deciding if a cheap CNC machine is the right choice for you.

Whether it's cheaper to build or buy a CNC machine depends on several factors, including your technical skills, time, budget, and the specific requirements of your project.

Convenience: Buying a ready-made CNC machine is generally more convenient. You can start using it right away without the time and effort required for You can start using it right away without the time and effort required for building one.

Reliability: Commercially available CNC machines from reputable manufacturers are typically well-designed and tested for reliability, accuracy, and durability. reliability, accuracy, and durability.

Warranty and Support: Many manufacturers offer warranties and customer support, which can be valuable if you encounter issues or need assistance.

Time Savings: Building a CNC machine from scratch or from a kit can be time-consuming, especially if you're new to CNC machining.

Cost: While buying a CNC machine is an upfront expense, it may be cost-effective for many users, especially those who don't have the expertise to build one Cost: While buying a CNC machine is an upfront expense it may be cost-effective for many users, especially those who don't have the expertise to build one.

Customization: Building your own CNC machine allows for greater customization. You can tailor it to your specific needs and add features that may not be available in commercial models. You can tailor it to your specific needs and add features that may not be available in commercial models.

Cost Savings for DIYers: If you have the technical skills and access to affordable components, building a CNC machine can be cheaper than buying a high-end commercial machine. Learning Experience: Building a CNC machine can be cheaper than buying a high-end commercial machine.

Learning Experience: Building a CNC machine can be a valuable learning experience. You'll gain a deeper understanding of CNC systems, electronics, and mechanics. You'll gain a deeper understanding of CNC systems, electronics, and mechanics.

Upgradeability: Since you built it, you'll have a better understanding of how to upgrade and maintain the machine over time.

Satisfaction: Many DIY enthusiasts find satisfaction in building their own CNC machines and take pride in the accomplishment.

Ultimately, the decision depends on your specific situation. If you have the technical skills, time, and interest to build a CNC machine and you require a highly customized solution, building might be the best option. If you have the technical skills, time, and interest to build a CNC machine and you require a highly customized solution, building might be the way to go. However, if you need a CNC machine quickly, lack the expertise or time to build one, or require a high level of reliability and support, buying a pre-made machine may be the better option.

It's important to carefully weigh the costs, benefits, and trade-offs of each approach before making a decision. Additionally, consider your long-term goals and how the CNC machine will work for you. It's important to carefully weigh the costs, benefits, and trade-offs of each approach before making a decision.

Revolutionizing Automotive Manufacturing with CNC Cutting Aluminum SheetsFebruary 29, 2024The Rise of CNC Cutting in Automotive ManufacturingIn the fast-paced world of automotive manufacturing, precision and efficiency are key factors that can make or break a company's success. One tec...view

Revolutionizing Automotive Manufacturing with CNC Cutting Aluminum SheetsFebruary 29, 2024The Rise of CNC Cutting in Automotive ManufacturingIn the fast-paced world of automotive manufacturing, precision and efficiency are key factors that can make or break a company's success. One tec...view What Are the Benefits of Cnc Precision Machining?October 25, 2023The sunk costs of CNC precise machining may be a bit higher than traditional machining methods. However, in the long run, the benefits offered by the process definitely make it worth the extra investment, and today Richconn will share with you what all the benefits of CNC machining are.view

What Are the Benefits of Cnc Precision Machining?October 25, 2023The sunk costs of CNC precise machining may be a bit higher than traditional machining methods. However, in the long run, the benefits offered by the process definitely make it worth the extra investment, and today Richconn will share with you what all the benefits of CNC machining are.view 4 Axis CNC Machining: The Definitive Guide 2023August 29, 2023CNC machining is a widely used manufacturing process that involves the use of computer-controlled machines to create precise and complex parts from various materials. CNC machines can operate on diffe...view

4 Axis CNC Machining: The Definitive Guide 2023August 29, 2023CNC machining is a widely used manufacturing process that involves the use of computer-controlled machines to create precise and complex parts from various materials. CNC machines can operate on diffe...view Cutting Costs, Not Quality: Exploring the Best Cheap CNC Material OptionsDecember 4, 2023In today's competitive market, every business is constantly finding ways to cut costs without compromising the quality of their products or services. When it comes to CNC machining, one of the mos...view

Cutting Costs, Not Quality: Exploring the Best Cheap CNC Material OptionsDecember 4, 2023In today's competitive market, every business is constantly finding ways to cut costs without compromising the quality of their products or services. When it comes to CNC machining, one of the mos...view Exploring Chameleon PVD Coating in DesignJanuary 5, 2024The world of design is constantly evolving, with new techniques and materials pushing boundaries and inspiring creativity. One such innovation that has revolutionized the design industry is Chameleon ...view

Exploring Chameleon PVD Coating in DesignJanuary 5, 2024The world of design is constantly evolving, with new techniques and materials pushing boundaries and inspiring creativity. One such innovation that has revolutionized the design industry is Chameleon ...view CNC Turning Process And Process AnalysisJune 21, 20221. The content of CNC turning processThe CNC turning process is the sum of the methods and technical means used when CNC lathes are used to process parts. Its main contents include the following aspec...view

CNC Turning Process And Process AnalysisJune 21, 20221. The content of CNC turning processThe CNC turning process is the sum of the methods and technical means used when CNC lathes are used to process parts. Its main contents include the following aspec...view

EN

EN

ru

ru