When it comes to construction and engineering, one material that stands out for its versatility and durability is galvanized sheet metal. In this comprehensive guide, I will take you on a journey through the world of galvanized sheet metal, exploring its various facets, applications, and even its synergy with CNC technology. So, let's dive right in and discover how this remarkable material can transform your projects and designs.

Galvanized sheet metal, at its core, is steel coated with a layer of zinc through a galvanization process. This process serves a dual purpose: it enhances the metal's resistance to corrosion and adds to its overall strength. Galvanized sheet metal is used extensively in construction, manufacturing, and various industrial applications due to its exceptional properties.

Galvanized sheet metal comes in a variety of types and specifications, catering to diverse project requirements. Understanding these variations is crucial for selecting the right material for your specific needs. Whether you need plain galvanized sheets or ones with specialized coatings, knowing the options available is essential.

One of the most significant advantages of galvanized sheet metal is its exceptional resistance to corrosion. The zinc coating acts as a barrier, preventing moisture and other corrosive agents from coming into contact with the underlying steel. This property makes galvanized sheet metal ideal for outdoor and marine applications, where exposure to moisture is a constant concern.

Galvanized sheet metal is built to last. Its resistance to rust and corrosion ensures a longer lifespan compared to untreated steel. Structures and components made from galvanized sheet metal can withstand harsh weather conditions, making them a reliable choice for both industrial and residential projects.

Another practical benefit of galvanized sheet metal is its low maintenance requirements. Once installed, it demands minimal upkeep. Periodic inspections and cleaning to remove surface contaminants are usually sufficient to keep it in top condition. This translates to cost savings in terms of maintenance and repair.

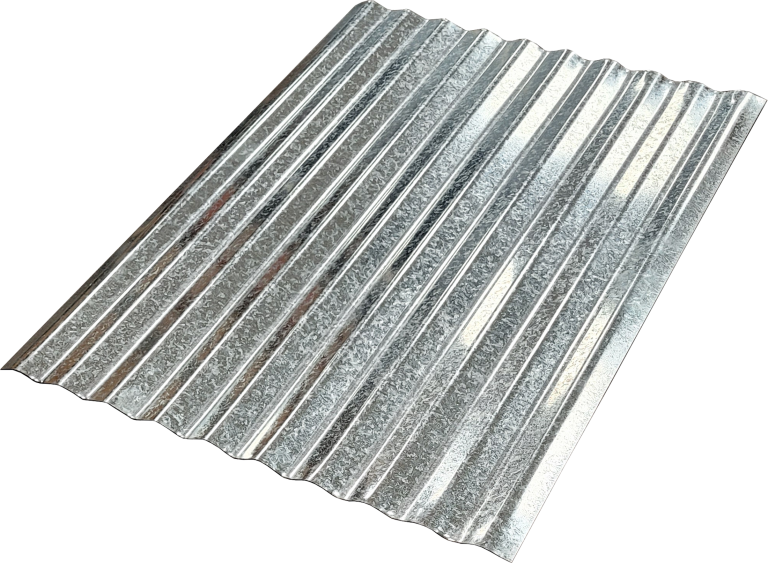

Corrugated galvanized sheet metal takes the versatility of galvanized steel to another level. With its unique wave-like pattern, it finds wide-ranging applications in roofing, siding, and agricultural structures. Its strength, coupled with an attractive appearance, makes it a popular choice in both industrial and residential settings.

The benefits of corrugated galvanized sheet metal are manifold. It provides structural integrity to buildings and is renowned for its ability to withstand harsh weather conditions. Moreover, its ease of installation and recyclability contribute to its eco-friendly profile.

Soldering galvanized sheet metal can be a precise task. To ensure a strong bond and minimize the risk of zinc fumes, use a soldering iron with temperature control. Remember to clean the surface thoroughly and apply flux for better adhesion. Safety measures, such as proper ventilation, are essential when working with galvanized materials.

Cutting and shaping galvanized sheet metal require the right tools and techniques. Utilize tools like shears, nibblers, or a circular saw with a carbide-tipped blade for clean and precise cuts. Wear appropriate safety gear and take precautions to avoid sharp edges.

In the industrial sector, galvanized sheet metal finds diverse applications. It is used for manufacturing components, machinery, and even storage tanks. Its resistance to corrosion ensures the longevity and reliability of industrial equipment.

In residential and architectural projects, galvanized sheet metal adds aesthetic value while delivering functionality. From roofing to decorative elements, it can enhance the visual appeal of a structure. Explore design possibilities and choose the right gauge and finish for your project.

CNC (Computer Numerical Control) technology has revolutionized metal fabrication processes. When combined with galvanized sheet metal, it allows for precision cutting, drilling, and shaping. CNC machines ensure high accuracy, making them ideal for intricate designs and complex projects. The computerized control system interprets CAD (Computer-Aided Design) files and executes precise movements, resulting in flawless metal components.

Utilizing CNC technology with galvanized sheet metal offers numerous advantages. Here are some key benefits:

Precision and Accuracy: CNC machines are capable of intricate and precise cuts, holes, and shapes, ensuring that your galvanized sheet metal components meet exact specifications.

Efficiency: CNC technology streamlines the manufacturing process, reducing waste and increasing productivity. It allows for consistent quality across multiple pieces.

Complex Designs: CNC machining can effortlessly create complex and intricate designs, enabling you to explore innovative possibilities in your projects.

Customization: CNC machines can quickly switch between different designs, making customization and prototyping more accessible and cost-effective.

Reduced Human Error: Automation through CNC minimizes the risk of human error, ensuring consistently high-quality results.

To leverage these benefits, consider partnering with a CNC service provider with expertise in working with galvanized sheet metal.

Proper maintenance is essential to prolong the life of galvanized sheet metal. Here are some tips to keep it in optimal condition:

Regular Cleaning: Periodically clean the surface to remove dirt, debris, and contaminants. Use a mild detergent or a mixture of vinegar and water.

Inspect for Corrosion: Regularly inspect the surface for signs of corrosion, such as white rust. Address any issues promptly.

Apply Zinc-Rich Paint: If needed, apply a zinc-rich paint or coating to maintain the protective zinc layer and prevent corrosion.

Avoid Abrasive Cleaners: Avoid abrasive cleaners or tools that may damage the zinc coating. Opt for gentle cleaning methods.

Understanding common issues with galvanized sheet metal can help you address them effectively:

White Rust: White rust is a common issue caused by moisture exposure. Prevent it by keeping the surface dry and applying a passivating solution if necessary.

Scratches and Damage: Address scratches or damage promptly by recoating affected areas with a zinc-rich paint or coating.

Galvanic Corrosion: Be cautious when using galvanized sheet metal in contact with dissimilar metals, as it can lead to galvanic corrosion. Use insulating materials or coatings to prevent this.

By following these maintenance tips and addressing issues promptly, you can ensure the longevity and durability of your galvanized sheet metal components.

When it comes to construction and engineering, one material that stands out for its versatility and durability is galvanized sheet metal. In this comprehensive guide, we've taken you on a journey through the world of galvanized sheet metal, exploring its various facets, applications, and even its synergy with CNC technology. From understanding the basics to mastering its applications and maintenance, we've covered it all.

Galvanized sheet metal, with its zinc-coated surface, offers a myriad of advantages. Its exceptional resistance to corrosion, longevity, and low maintenance requirements make it a top choice in various industries. Whether you're in the industrial sector, working on residential projects, or involved in architectural designs, galvanized sheet metal can add both functionality and aesthetic value to your creations.

Additionally, the integration of CNC technology with galvanized sheet metal opens up new avenues for precision and customization. The role of CNC in metal fabrication cannot be overstated, as it ensures accuracy and efficiency in creating intricate designs and complex components.

To maximize the potential of galvanized sheet metal, it's crucial to follow proper maintenance and care practices. Regular cleaning, inspection for corrosion, and timely addressing of issues are key to ensuring the material's longevity.

As you embark on your projects and designs, consider the remarkable properties of galvanized sheet metal and its vast potential. By utilizing this material effectively and staying informed about industry trends, you can create lasting and impressive structures while contributing to sustainability and environmental considerations.

Galvanized sheet metal is more than just a building material; it's a powerful tool that empowers creativity and innovation. So, go ahead, explore the possibilities, and let galvanized sheet metal elevate your next endeavor!

What Is a Heat Sink? 7 Tips for Choosing the Right Heat SinkSeptember 5, 2023Because of the increasing need for high-performance electronics, advanced devices with fast microprocessors and high transistor densities are being manufactured. This technical modification in such el...view

What Is a Heat Sink? 7 Tips for Choosing the Right Heat SinkSeptember 5, 2023Because of the increasing need for high-performance electronics, advanced devices with fast microprocessors and high transistor densities are being manufactured. This technical modification in such el...view CNC Honing Service A Guide for Concept & SelectionMay 20, 2024CNC honing service helps to achieve tighter tolerances and better surface finishes on a wide range of precision machined parts with a round bore. Here's a simple guide for its concept and selection.view

CNC Honing Service A Guide for Concept & SelectionMay 20, 2024CNC honing service helps to achieve tighter tolerances and better surface finishes on a wide range of precision machined parts with a round bore. Here's a simple guide for its concept and selection.view What Kind of Parts Are 5-Axis Suitable for Machining?October 30, 2023Over the past few years, CNC machining technology has evolved from simple machines to more complex ones. 5-axis CNC machining is one of the most advanced machining processes available today. It utilizes subtractive machining techniques that offer endless possibilities for part creation. The technology uses cutting tools that work on 5 axes to cut the workpiece into the desired shape and size.view

What Kind of Parts Are 5-Axis Suitable for Machining?October 30, 2023Over the past few years, CNC machining technology has evolved from simple machines to more complex ones. 5-axis CNC machining is one of the most advanced machining processes available today. It utilizes subtractive machining techniques that offer endless possibilities for part creation. The technology uses cutting tools that work on 5 axes to cut the workpiece into the desired shape and size.view The Glass Transition Temperature of PolymersOctober 17, 2023When designing parts for plastic injection molding, there is an important but often overlooked material consideration. It involves the glass transition temperature, or Tg. We'll get into the underlying science later, but for now, keep in mind that there is a temperature at which amorphous materials transition from a glassy/rigid state to a leathery/rubbery state.view

The Glass Transition Temperature of PolymersOctober 17, 2023When designing parts for plastic injection molding, there is an important but often overlooked material consideration. It involves the glass transition temperature, or Tg. We'll get into the underlying science later, but for now, keep in mind that there is a temperature at which amorphous materials transition from a glassy/rigid state to a leathery/rubbery state.view Precautions for Stamping Dies 1July 11, 2023Spring compression and calculationIn a set of stamping dies, more elastic materials need to be used, including springs of different specifications, urethane, nitrogen springs, etc., and different elas...view

Precautions for Stamping Dies 1July 11, 2023Spring compression and calculationIn a set of stamping dies, more elastic materials need to be used, including springs of different specifications, urethane, nitrogen springs, etc., and different elas...view Key Points in Precision Mold Processing TechnologyJuly 21, 2023Precision mold making is a crucial process that requires specialized skills, knowledge, and tools. It involves the creation of tools that are used to produce other parts or products. The quality of th...view

Key Points in Precision Mold Processing TechnologyJuly 21, 2023Precision mold making is a crucial process that requires specialized skills, knowledge, and tools. It involves the creation of tools that are used to produce other parts or products. The quality of th...view

EN

EN

ru

ru