CNC milling is generally a metal fabrication process; however, plastics can also be machined. CNC milling uses a computer to control the tool. The cutting tool then cuts the material from the workpiece to produce the desired shape/pattern.

The tool is the main working part of a CNC milling machine and can be moved in three or more axes. Normally, the workpiece remains stationary, however, modern CNC mills can swing or turn the workpiece for better cutting angles. This feature also speeds up the process, as the machinist does not need to reorient the workpiece when milling complex designs.

CNC milling is a fairly simple process, which is why it is the most widely used production process in the metal industry. From prototype to final design, everything is usually done in a CNC milling machine.

In the long run, CNC milling can be useful to industrialists who handle multi-functional and complex-shaped products. This type of machining is an excellent way to produce this type of product.

CNC milling has the following characteristics:

The productivity of CNC milling is best suited for batch processing. Simply put, CNC milling equips businesses that produce small batches of parts in a single run.

CNC milling machines are designed to save and minimize material usage. Compared to CNC turning, the material consumption of the CNC milling method is significantly lower. In the long run, this directly means lower material costs and better waste management in the Health Safety Environment (HSE) sector.

Milling does not necessarily require the use of explicit tools. You can do all kinds of things with a completely different set of cutting tools. Not only is this better than a lathe, but it makes them work more efficiently.

Also, you can produce complex shaped tools on a milling machine, but you will be limited by the lathes that are often used in turning operations.

CNC milling can produce a wide variety of parts. It can handle both complex shaped parts as well as simple parts. This makes it a versatile choice for industrialists. However, it's not the only best thing to do with CNC milling, it's also proven to be a faster, more economical, and more accurate production operation.

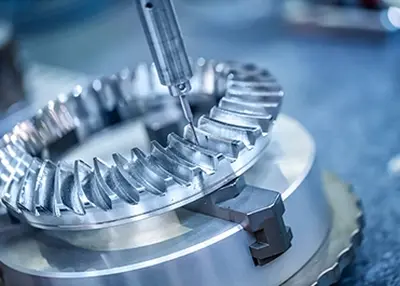

How Many Types of Gears Are There? What Common Materials Are Suitable for Making Gears?October 26, 2023Gears are mechanical parts with teeth that can mesh with each other, and they are widely used in mechanical transmission and the whole mechanical field. There are many types of gears, mainly reclusive gear axis classification, generally divided into parallel shaft, intersecting shaft and staggered shaft three types.view

How Many Types of Gears Are There? What Common Materials Are Suitable for Making Gears?October 26, 2023Gears are mechanical parts with teeth that can mesh with each other, and they are widely used in mechanical transmission and the whole mechanical field. There are many types of gears, mainly reclusive gear axis classification, generally divided into parallel shaft, intersecting shaft and staggered shaft three types.view CNC Milling vs CNC Turning: Which Machining Process is Best for YouNovember 23, 2023CNC milling and CNC turning are two commonly used CNC machining methods, and they both utilize the CNC system to control the movement of the machine tool and achieve precise machining of the workpiece.view

CNC Milling vs CNC Turning: Which Machining Process is Best for YouNovember 23, 2023CNC milling and CNC turning are two commonly used CNC machining methods, and they both utilize the CNC system to control the movement of the machine tool and achieve precise machining of the workpiece.view What are Corrosion Resistant Alloys?November 23, 2023Corrosion-resistant alloys are metallic materials that have the ability to resist media attack, and they are widely used in a variety of industries, especially in chemical processing, energy, marine, and aerospace, to provide reliable performance and safety.view

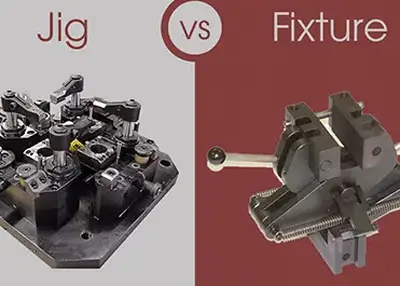

What are Corrosion Resistant Alloys?November 23, 2023Corrosion-resistant alloys are metallic materials that have the ability to resist media attack, and they are widely used in a variety of industries, especially in chemical processing, energy, marine, and aerospace, to provide reliable performance and safety.view Jig vs Fixture: Understanding the Differences and Applications of Two Common Workholding DevicesDecember 1, 2023Jig vs Fixture is a common topic in manufacturing and engineering. Jigs and fixtures are two types of devices that are used to hold, support, and locate workpieces during machining or assembly processes. However, they have some differences in their design, function, and application.view

Jig vs Fixture: Understanding the Differences and Applications of Two Common Workholding DevicesDecember 1, 2023Jig vs Fixture is a common topic in manufacturing and engineering. Jigs and fixtures are two types of devices that are used to hold, support, and locate workpieces during machining or assembly processes. However, they have some differences in their design, function, and application.view Exploring the World of Medical Machined Parts: Precision in HealthcareNovember 10, 2023In the ever-evolving landscape of healthcare, the role of medical machined parts stands as a testament to precision engineering's indispensable contribution. As the CEO of Richconn, I am thrilled to guide you through an extensive exploration of these critical components.view

Exploring the World of Medical Machined Parts: Precision in HealthcareNovember 10, 2023In the ever-evolving landscape of healthcare, the role of medical machined parts stands as a testament to precision engineering's indispensable contribution. As the CEO of Richconn, I am thrilled to guide you through an extensive exploration of these critical components.view MIG Welding vs. TIG Welding: Choosing the Right Welding MethodSeptember 25, 2023MIG vs. TIG welding: Master the art, choose wisely. Explore techniques, applications, and trends for welding success.view

MIG Welding vs. TIG Welding: Choosing the Right Welding MethodSeptember 25, 2023MIG vs. TIG welding: Master the art, choose wisely. Explore techniques, applications, and trends for welding success.view

EN

EN

ru

ru