Rivets are parts that join multiple components and structures together to form a complete body. These parts can be manipulated with some specialized tools. One of the panaceas of manufacturing is rivets. Depending on their design requirements and performance, different types of rivets can be used.

These rivets offer incredible tightening capabilities in light and heavy duty applications.

This makes them extremely valuable in a variety of environments, from aircraft construction and bridge splicing to submarines and sheet metal window and door assemblies.

This article will help you fully understand the various types of rivets, structures, and their uses. Let's get straight to the point!

Rivet is a simple and practical metal connector, easy to use and maintain, is an indispensable fastening part in industry and daily life. So let's start with what rivets.

Rivets are commonly used mechanical fasteners to firmly join metal fasteners that hold two or more workpieces together.

Its main structure is composed of two parts: rivet head and rivet handle, usually the head is thicker and the shank is thinner. The working principle is to first pass the shank of the rivet through the hole of the workpiece that needs to be connected, and then use hammering or pressure to mechanically expand the rivet head to deform it, so that the rivet head is firmly buckled on the surface of the workpiece to achieve a fastening connection.

Rivets are usually made of aluminum, steel, polymer materials, etc., but some are also made of other composite materials. These types of fasteners are not tightened like the usual bolts and nuts. Using a unique rivet mounting method helps ensure permanent parts are assembled or joined. Rivets are widely used in engineering, construction, automotive, aerospace, and other fields because they provide a solid connection that resists vibration and external forces while not requiring accessible space on the other side of the connection.

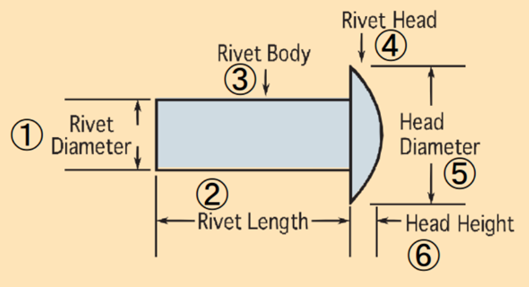

The structure of rivets is mainly composed of the following parts:

Rivets Head

The rivet head is located at one end of the rivet and is larger in diameter than the rivet handle. When in use, the head is deformed by force, so that the rivet is fixed on the connected workpiece. Common rivet head shapes are:

(1) Flat head: The head is flat, which is the most widely used.

(2) Semi-circular head: The head is semi-circular.

(3) Upsetting: The head is cylindrical, and the length is greater than the diameter.

(4) Punch: The head is slightly pointed to facilitate initial positioning.

Rivets Shank

The rivet shank is an elongated cylinder that connects the head and tail. The diameter of the shank is generally uniform, and some rivets have a taper transition at the junction of the head to the shank.

Rivets Point

The end of the rivet is the tip, which is used to guide the rivet into the hole connecting the workpiece. Some rivet tails are machined into chamfers or spheres.

Rivets neck

The transition between the head and the shank, some rivets are machined on the neck to improve stress distribution.

In addition, some special rivets will have structures such as cones or corrugations to suit specific applications. Rivets of different materials and sizes will also design different structural proportions due to stress requirements.

Rivets are an indispensable tool in machines and structures. You can install rivets by drilling, punching, or placing them in holes and deforming the tail. The most popular riveting process involves drilling holes in the parts to be riveted. This is because it is simpler and more accessible.

The rivets are installed in drilled holes that are about 1.5 mm longer than the rivet diameter to hold the rivets better. As soon as the rivet is installed, the tail comes out from the other end, where it deforms. When you mash or smash the tail of the rivet, it flattens the material, which usually causes the tail to unfold or unfold. It spreads to about one and a half times the original size.

In other words, you can create a dumbbell-sized rivet by tapping or pulling to break the tail flat at one end and create a new head at the other. After that, the tail takes on the shape of a dumbbell. In this way, the joints are riveted.

The main advantages of rivets include:

Rivets are easy to install, only need to hammer or use rivet guns to complete the installation, no additional tools or equipment, installation efficiency.

After the rivet head is deformed, a great fastening force can be generated, so that the connected parts are firmly combined, and the tensile strength and shear strength are good.

Compared with screws, rivets are not easy to loosen, have a long service life, and are not easy to reduce the connection strength due to corrosion.

The material and processing process of rivets are simple, and the cost of mass production is low.

Compared to bolt nuts, rivets have low requirements for the diameter tolerance of the precast holes, and do not require a precise fit during installation.

Rivets are thinner overall, often used in applications where space is limited.

Many metal rivets have good electrical and thermal conductivity.

Choose from removable or non-removable rivets as needed.

After the rivet head is deformed, there is a mechanical wedge locking effect, and the connection is not easy to loosen.

Compared to bolt nuts, rivets can be used for holes of any shape, and are not required to be round holes.

Some rivets made of soft or plastic materials can achieve a certain sealing effect in occasions with low sealing requirements.

Before final assembly, rivets can be used for temporary positioning of components.

One rivet can be fastened quickly through multiple parts.

For joining sheet materials, rivets are a good choice.

Many metal rivets have good corrosion protection and are suitable for harsh environments such as outdoor and humid.

In summary, rivets are quick and easy to install, compact in structure, stable and reliable in performance, and are ideal fasteners for a wide range of applications.

Almost nothing has its advantages without disadvantages or limitations. So, here are some of the disadvantages of riveting:

Ordinary rivets cannot be removed after installation, and repairs and replacement parts require cutting or drilling.

Rivet joints are prone to stress concentration and may wear out the joints.

Rivets need to be installed using a hammer or a special rivet gun, which is relatively inconvenient.

Hammering or pressure during installation may damage the surface of the joint.

The connection part needs to be cleaned in advance to remove dust and grease, otherwise it will affect the fixing effect.

Under long-term force vibration, rivets will cause fatigue failure.

Rivets have lower tensile shear strength compared to high-strength bolts.

Contact with different metals may cause galvanic corrosion and reduce the strength of the connection.

Compared to bolted connections, rivet connections are less accurate.

Rivet connections are not suitable for gas-tight or liquid-tight applications.

There are several metal materials that can be used to make rivets. They include steel, copper, brass, aluminum, copper, and stainless steel. Designers and manufacturers choose these different materials to meet their needs.

With these huge materials, rivets now have unlimited applications. Therefore, it is recommended to choose a rivet manufacturing material that matches the performance of the parts to be joined together.

Iron rivets have the lowest price and average tensile strength, and are often used for temporary assembly or non-critical connections.

Low carbon steel rivets have higher strength, higher price and good versatility.

High-strength steel rivets have high tensile strength, but they are also more expensive. It is used for structural connections that require high strength.

Copper rivets have good conductivity and are used for conductive connections, but the strength is lower.

Aluminum rivets are lightweight and can be used in areas where lightweight is required, such as aircraft.

Nickel rivets have strong corrosion resistance and are used in applications that require corrosion resistance such as ships.

Titanium rivets are strong, very light and corrosion-resistant and are used in high-end aircraft and spacecraft.

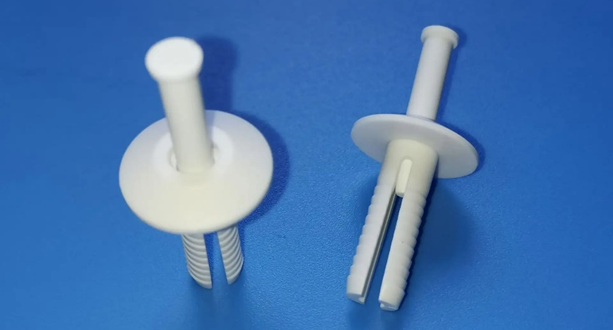

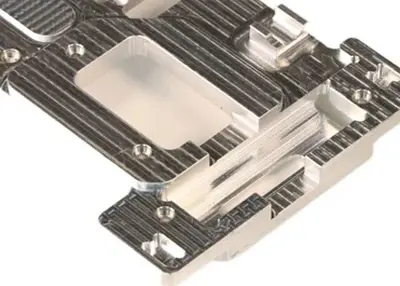

Polymer rivets are lightweight and durable for temporary positioning or internal connections of electronics.

Stainless steel rivets are highly corrosion-resistant and used in corrosive environments.

NdFeB rivets have strong magnetic retention and are used for permanent magnet equipment connection.

Different types of rivets that can be used for manufacturing

There are several different types of rivets to choose from. However, they are broadly divided into the following categories.

Of course, here is a summary of the various rivets:

Solid rivets: A basic rivet type for applications requiring strength and durability.

Blind rivets: Rivets installed from one side, do not require back access, suitable for a variety of connections.

Pressure rivets: used for softer materials, forming connections by compression.

Hollow rivets: suitable for light duty applications such as joining leather and fabric.

Tapered rivets: commonly used in aviation manufacturing, the diameter of one end of the shank is large, and gradually tapered towards the other end.

Semi-hollow rivets: used when it is necessary to keep one side smooth, the shank is partially formed or hollow.

Split rivets: suitable for soft materials such as leather, the shank is inserted into the hole and unfolded.

Threaded rivets: have threaded shanks that screw into pre-threaded holes.

Multi-layer rivets: unique design to adapt to different material thicknesses.

Oscar rivets: Speed rivets with a locking mechanism to prevent loosening.

Crushed rivets: Used in electronic devices, the shank is crushed during installation to secure the element.

Tinsmith rivets: used for sheet metal, often used to join thin metal sheets.

Cherry Max rivets: High-strength blind rivets for aerospace applications.

Tribex rivets: for applications that require larger surface area to disperse loads.

Bulb-tite rivets: Create a waterproof seal suitable for waterproof requirements.

T-rivet: Features a T-shaped head for automotive applications.

Drive pin rivets: Similar to blind rivets, they have a solid head.

Self-perforating rivets: for joining materials that are difficult to pre-perforate.

Huck bolts: similar to rivets, installed using special tools.

Solid rivets: The most common rivets

These rivets are the most common type of rivet. They are simple, reliable and the oldest form of joining material. These simple tools consist of a solid shaft whose head is on a specific side once the hole is punched. The headless part at the other end is deformed using a rivet gun or hammer.

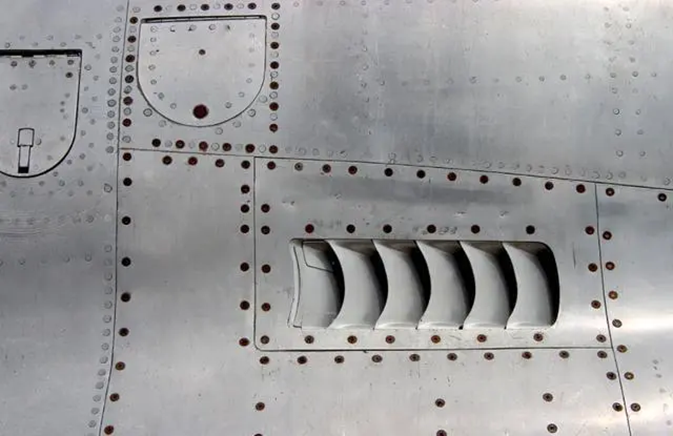

Solid rivets consist only of a shaft and a head, deformed using a rivet gun or hammer. These types of rivets can come with a 100-degree countersunk or round gimbal. Solid rivets are often used in situations where safety and reliability are critical. For example, one of the typical applications is structural components for aircraft.

Blind rivets: Also known as popular rivets

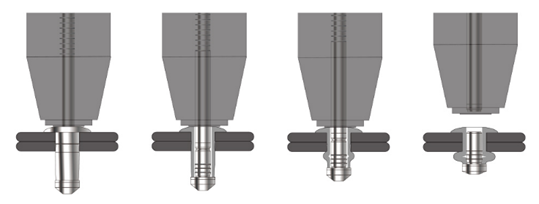

Blind rivets are also known as hollow or pop-out rivets. These metal rivets are tubular fasteners with a mandrel in the center. The manufacturer inserts blind rivets into the drilled holes used for joining the parts.

The blind end of the rivet expands, causing the mandrel to break. Unlike solid rivets, you can install blind rivets in the joint from one side of the part. In this way, they "turn a blind eye" to the other side. Blind rivets are suitable for situations where it is difficult to see the rear end of the joint. Like any other rivet, it is very simple and quick to apply. It is the most important joint in the aerospace, electronics and shipbuilding industries.

Some common blind rivets that can be used are:

Pull Mandel Rivet

Is a special double countersunk blind rivet that provides flush surface riveting on both sides of its application. Here, the mandrel head does not break, providing a consistent clamping force. In addition, the tight radial setting in these rivets increases structural stiffness.

Threaded rivets

Also known as blind rivet nuts or threaded inserts. Manufacturers can anchor this variant of standard blind rivets from the side where the part is mounted. There are standard and heavy-duty threaded rivets. The standard option satisfies almost all blind applications with permanent installation. However, heavy-duty rivets have heavy-duty sidewalls and heads. As a result, they contribute to high-performance and demanding applications.

Drive Pin Rivets

These types of blind rivets have short mandrels protruding from the head. Once the drive pin rivet is inserted into the hole, its mandrel can work using a hammer or other material. This causes the rivet end inside the hole to open. Drive pin rivets are more popular in architectural and other aesthetic applications because they do not require drilling. However, you must note that they have less clamping force than many other types of rivets.

Tubular rivets: with hollow ends

They are partially hollow rivets with many different configurations. Universal tubular rivets have a manufacturing head on one side and a hollow end on the other. The hollow ends are connected through each piece. Manufacturers typically cold form the hollow end into a field head.

Since these rivets require extensive cold forming, they must have strong ductility and low strength metals. Therefore, tubular rivets are popular in commercial applications. Some specific tubular rivet types are:

Compression Tubular Rivets

These rivets consist of two parts with an interference fit during the fastening process. Their commercial use is soft materials that need to be aesthetically pleasing on both sides of the component.

Full tubular rivets

They have deeper holes than comparable products. They are also usually weaker than semi-tubular rivets. However, they can easily pierce softer materials such as fabrics and plastics.

Semi-tubular rivets

These types of rivets have holes at the field end. The hole depth is usually about 1.12 of the shank diameter. Therefore, semi-tubular rivets may feel like solid rivets when forming a field head.

Split rivets: Home repair rivets

Forked rivets, also known as forked rivets, are closely related to self-piercing rivets. They are the best choice for joining softer materials such as leather, plastic, and wood.

Split rivets are available in split or saw bodies and are suitable for home repairs. In addition, they have sharp ends or tips that allow them to punch holes in the material itself. They are not recommended for extreme or critical applications.

Flush rivets: Also known as countersink rivets

Flush rivets, also countersunk rivets are used on the outer surface to ensure a good appearance and eliminate air resistance.

This is due to the fact that it uses both countersinks and heads. To reduce drag and turbulence (for aerodynamic reasons), flush rivets work on the exterior of the aircraft. More post-installation operations may be required to improve airflow.

Self-piercing rivets: strong column strength

These rivets do not require drilling or drilling before use. This is because the ends of these rivets have bevel drills or chamfer pokes to pierce the parts involved. Self-piercing rivets pass through the top layer of the material while perforating the bottom half to form an airtight or watertight joint. The upsetting mold causes the rivet tail to flared and interlock on the base plate, creating a low-profile button.

Friction lock rivets: similar to expansion bolts

They are made in cupola or countersunk form. These friction lock rivets are similar to expansion bolts.

The difference is that as long as there is a sufficiently high tension, their shaft will break below the surface. Friction lock rivets are a primitive form of blind rivets commonly used in light aircraft maintenance in the aerospace sector.

If you need CNC machining metal rivets, RICHCONN is your best partner.

Try it now quickly and directly!

All information and uploads are secure and confidential.

Rivets are a type of fastener commonly used to join metal parts. The following points need to be observed when using rivets:

1. Choose the right rivet size. According to the material and thickness of the connection, choose the appropriate size rivet. The diameter of the rivet needs to be smaller than the diameter of the hole in the connection.

2. Pre-drill holes in the joints. Using a suitable drill, pre-drill the clamping hole where the two components that need to be connected coincide, the diameter of the hole is slightly larger than the diameter of the rivet. Make sure the positions of the two holes are precisely aligned.

3. Insert the rivets. Insert the rivet into the pre-drilled hole, with the rivet head on one side and the tail exposed from the other. Make sure the rivet head is flush with the surface of the part.

4. Clamp with a rivet gun. From the exposed rivet tail position, use the tool head in the rivet gun to press the rivet tail so that the rivet head unfolds and fastens the two parts.

5. Check the connection. Check that the rivet head is sufficiently spread and flush with the surface of the part. Check that the two parts are securely connected. If necessary, gently tap the rivet head with a hammer to make sure the connection is secure.

6. Safety Precautions. Wear goggles when operating the rivet gun, as there is a risk of injuring the eyes when the rivet pops out. Keep the rivet gun perpendicular to the connection surface to avoid skew of the rivets.

The main purpose of rivets is to ensure a firm and reliable tightening of two or more metal or wood materials. When you do this, your joint is stronger than the joint of a screw of the same diameter.

Here are some uses for rivets:

Early aircraft mainly used wooden trusses and canvas skin structures. At that time, although riveting was also used, it was far less used than today's aircraft. With the continuous development of aircraft, flight speed and altitude continue to increase, especially after high-hardness aluminum alloy has become the main material of aircraft manufacturing, the drawbacks of aluminum alloy high temperature and easy deformation, reduced mechanical properties are increasingly apparent, and the resonance and stress change in flight make the welding point very easy to break, therefore, riveting has become the final choice for the connection of aircraft parts.

The high operating speed and large space of the aircraft put forward strict requirements for its reliability. Rivets are characterized by simple process, easy disassembly and strong reliability, so that they can be used in aircraft. At present, the specific strength of rivets is required to be as high as 1100 MPa, which is equivalent to the weight of 10 cars in an area of 1 square centimeter.

The links of many parts of the car are shockproof, relaxed and easy to replace after damage, metal rivets and plastic rivets are widely used in the car, such as: door inner village, hood, storage box, chassis components, bumper, door hinge, dashboard. It has many points such as high strength, easy installation, no machining, and strong connection.

Bridge riveting with its unique characteristics, rapid installation, large clamping force, good seismic resistance, stable and reliable performance. Rivets play an important role, riveted iron tower has excellent fastening, fire performance, non-magnetic, heat insulation, light weight, high temperature resistance, corrosion resistance, in the famous Sydney Bridge, the world's first large single-hole arch bridge, the bridge is fixed by 6 million rivets, the maximum rivet weight 3.5 kg; also made the Eiffel Tower in France stand for 132 years. China's Nanjing Yangtze River Bridge uses more than 1.5 million rivets.

Perhaps we will often see gold rivets used on the doors of ancient buildings, high-end and magnificent. In fact, rivets in modern architecture are also integrated into all aspects of us. These rivets may appear on the ceiling frame of the house, on the links of ventilation ducts, on the roof solar tiles, on the fixing of doors and windows, and so on.

Rivets are a good alternative to screws, bolts and nuts. They have proven to be more efficient and reliable than all other connectors. Today, different types of rivets serve different purposes. This is a consequence of the dynamic nature of machines and structures. However, you must choose the right metal rivet for your application to get the best results.

RICHCONN provides the necessary CNC machined metal rivets. We also provide the best customized precision CNC machining services for prototyping and production processing. Our professional technicians have the right experience to provide the best service for the expected results in a fast lead time.

Whenever you need the best metal rivets for CNC machining, contact RICHCONN.

A: Rivet is a fastener used for mechanical connection between metal plates. It consists of a head and a body, and by using a special rivet gun, the rivet head can be unfolded and deformed, and the two parts can be locked and fixed.

A: The commonly used materials for rivets are carbon steel, alloy steel, copper, aluminum and other metal materials. Depending on the usage environment, different materials will be selected.

A: To use rivets, you need to drill holes first, and the aperture diameter is slightly larger than the diameter of the rivet body; Then insert the rivet and hit the rivet head vertically with a rivet gun to unfold; Finally, check whether the rivet head is fully extended to ensure the strength of the connection.

A: Compared with screw connection, rivet connection strength is higher, no thread cutting is required, and the operation is easier and faster. Rivet connections are also more convenient than welding.

A: Rivets can be removed using a special rivet removal tool, or the rivet head can be deformed and detached by hammer strikes. After disassembly, it is necessary to replace the rivets and reconnect them.

A: Rivets are widely used in mechanical connection of metal parts in machinery manufacturing, metal structure, aerospace, rail transit, automobile manufacturing and other fields.

All the Information You Need to Know About Polishing Surface FinishMarch 1, 2024Here is all the information. Learn more about the necessary details to guarantee your project's success. Check it out.view

All the Information You Need to Know About Polishing Surface FinishMarch 1, 2024Here is all the information. Learn more about the necessary details to guarantee your project's success. Check it out.view What Is CNC Machining? The Basic Information You Need to KnowMarch 27, 2024What is CNC machining? Here is the basic information that you must know, such as its advantages, disadvantages, applications, and so on.view

What Is CNC Machining? The Basic Information You Need to KnowMarch 27, 2024What is CNC machining? Here is the basic information that you must know, such as its advantages, disadvantages, applications, and so on.view Differences Between Chrome, Galvanized and Nickel PlatingOctober 20, 2023The electroplating process is widely used in industrial design to provide a variety of functional and aesthetic properties by forming a fine layer of different metals or alloys on the surface of an object. This process is usually carried out using the principle of electrolysis, which helps in preventing oxidation of the metal and improves abrasion resistance, light reflection, electrical conductivity, corrosion resistance, and other important properties.view

Differences Between Chrome, Galvanized and Nickel PlatingOctober 20, 2023The electroplating process is widely used in industrial design to provide a variety of functional and aesthetic properties by forming a fine layer of different metals or alloys on the surface of an object. This process is usually carried out using the principle of electrolysis, which helps in preventing oxidation of the metal and improves abrasion resistance, light reflection, electrical conductivity, corrosion resistance, and other important properties.view The Role of CNC Automotive Parts in Automotive IndustryJune 17, 2024CNC machining is often used for complex designs, small products and parts. With CNC machine tools, a wide range of parts can be processed more accurately.With the rapid development of the automotive i...view

The Role of CNC Automotive Parts in Automotive IndustryJune 17, 2024CNC machining is often used for complex designs, small products and parts. With CNC machine tools, a wide range of parts can be processed more accurately.With the rapid development of the automotive i...view Unraveling the World of Machined Springs: Your Ultimate GuideNovember 9, 2023As a CNC machining service provider, we at Richconn understand the significance of precision engineering and how it's all about the details. In the realm of mechanical components, one topic that piques the curiosity of engineers, manufacturers, and professionals alike is -Machined Springs. In this comprehensive guide, I will walk you through the intricacies of Machined Springs, from the fundamentals to their applications, performance characteristics, manufacturing processes, and more.view

Unraveling the World of Machined Springs: Your Ultimate GuideNovember 9, 2023As a CNC machining service provider, we at Richconn understand the significance of precision engineering and how it's all about the details. In the realm of mechanical components, one topic that piques the curiosity of engineers, manufacturers, and professionals alike is -Machined Springs. In this comprehensive guide, I will walk you through the intricacies of Machined Springs, from the fundamentals to their applications, performance characteristics, manufacturing processes, and more.view CNC Plastics Selection Guide | Machining MaterialsJune 18, 2024Delve into the realm of engineering plastics to discover a wide range of materials, their unique characteristics, and diverse processing techniques.view

CNC Plastics Selection Guide | Machining MaterialsJune 18, 2024Delve into the realm of engineering plastics to discover a wide range of materials, their unique characteristics, and diverse processing techniques.view