In sheet metal work, the term "gauge" is frequently employed to specify thickness. Gauges are the units used to indicate the thickness of a metal sheet.

Gauge (Ga.) is a unit of measurement for diameters originating in North America, part of the Browne & Sharpe metering system. Initially utilized in fields like medicine and jewelry, the gauge system operates on an inverse relationship: the higher the number, the thinner the diameter. This system now also denotes thickness.

Ga. measurements differ from inches and lack a direct conversion formula. Even if two materials, like non-ferrous metal and steel, share the same gauge, their actual thicknesses vary.

Refer to the chart below for the conversion between gauge measurements and millimeters/inches for various sheet metal materials.

| Gauge Number | Standard Steel (mm) | Galvanized Steel (mm) | Stainless Steel (mm) | Aluminum, Brass, Copper (mm) |

|---|---|---|---|---|

| 3 | 6.073 | 5.827 | ||

| 4 | 5.095 | 5.954 | 5.189 | |

| 5 | 5.314 | 5.555 | 4.62 | |

| 6 | 4.935 | 5.159 | 4.115 | |

| 7 | 4.554 | 4.763 | 3.665 | |

| 8 | 4.176 | 4.191 | 3.264 | |

| 9 | 3.797 | 3.891 | 3.967 | 2.906 |

| 10 | 3.416 | 3.51 | 3.571 | 2.588 |

| 11 | 3.038 | 3.132 | 3.175 | 2.304 |

| 12 | 2.657 | 2.753 | 2.779 | 2.052 |

| 13 | 2.278 | 2.372 | 2.38 | 1.829 |

| 14 | 1.897 | 1.994 | 1.984 | 1.628 |

| 15 | 1.709 | 1.803 | 1.786 | 1.45 |

| 16 | 1.519 | 1.613 | 1.588 | 1.29 |

| 17 | 1.367 | 1.461 | 1.427 | 1.151 |

| 18 | 1.214 | 1.311 | 1.27 | 1.024 |

| 19 | 1.062 | 1.158 | 1.11 | 0.912 |

| 20 | 0.912 | 1.006 | 0.953 | 0.813 |

| 21 | 0.836 | 0.93 | 0.874 | 0.724 |

| 22 | 0.759 | 0.853 | 0.792 | 0.643 |

| 23 | 0.683 | 0.777 | 0.714 | 0.574 |

| 24 | 0.607 | 0.701 | 0.635 | 0.536 |

| 25 | 0.531 | 0.627 | 0.556 | 0.455 |

| 26 | 0.455 | 0.551 | 0.475 | 0.404 |

| 27 | 0.417 | 0.513 | 0.437 | 0.361 |

| 28 | 0.378 | 0.475 | 0.396 | 0.32 |

| 29 | 0.343 | 0.437 | 0.358 | 0.287 |

| 30 | 0.305 | 0.399 | 0.318 | 0.254 |

| 31 | 0.267 | 0.361 | 0.277 | 0.226 |

| 32 | 0.246 | 0.34 | 0.259 | 0.203 |

| 33 | 0.229 | 0.239 | 0.18 | |

| 34 | 0.208 | 0.218 | 0.16 | |

| 35 | 0.191 | 0.198 | 0.142 | |

| 36 | 0.17 | 0.178 | 0.127 | |

| 37 | 0.163 | 0.168 | 0.113 | |

| 38 | 0.17 | 0.157 | 0.101 |

| Gauge Number | Standard Steel (in) | Galvanized Steel (in) | Stainless Steel (in) | Aluminum, Brass, Copper (in) |

|---|---|---|---|---|

| 3 | 0.2391 | 0.2294 | ||

| 4 | 0.2242 | 0.2344 | 0.2043 | |

| 5 | 0.2092 | 0.2187 | 0.1819 | |

| 6 | 0.1943 | 0.2031 | 0.162 | |

| 7 | 0.1793 | 0.1875 | 0.1443 | |

| 8 | 0.1644 | 0.165 | 0.1285 | |

| 9 | 0.1495 | 0.1532 | 0.1562 | 0.1144 |

| 10 | 0.1345 | 0.1382 | 0.1406 | 0.1019 |

| 11 | 0.1196 | 0.1233 | 0.125 | 0.0907 |

| 12 | 0.1046 | 0.1084 | 0.1094 | 0.0808 |

| 13 | 0.0897 | 0.0934 | 0.0937 | 0.072 |

| 14 | 0.0747 | 0.0785 | 0.0781 | 0.0641 |

| 15 | 0.0673 | 0.071 | 0.0703 | 0.0571 |

| 16 | 0.0598 | 0.0635 | 0.0625 | 0.0508 |

| 17 | 0.0538 | 0.0575 | 0.0562 | 0.0453 |

| 18 | 0.0478 | 0.0516 | 0.05 | 0.0403 |

| 19 | 0.0418 | 0.0456 | 0.0437 | 0.0359 |

| 20 | 0.0359 | 0.0396 | 0.0375 | 0.032 |

| 21 | 0.0329 | 0.0366 | 0.0344 | 0.0285 |

| 22 | 0.0299 | 0.0336 | 0.0312 | 0.0253 |

| 23 | 0.0269 | 0.0306 | 0.0281 | 0.0226 |

| 24 | 0.0239 | 0.0276 | 0.025 | 0.0211 |

| 25 | 0.0209 | 0.0247 | 0.0219 | 0.0179 |

| 26 | 0.0179 | 0.0217 | 0.0187 | 0.0159 |

| 27 | 0.0164 | 0.0202 | 0.0172 | 0.0142 |

| 28 | 0.0149 | 0.0187 | 0.0156 | 0.0126 |

| 29 | 0.0135 | 0.0172 | 0.0141 | 0.0113 |

| 30 | 0.012 | 0.0157 | 0.0125 | 0.01 |

| 31 | 0.0105 | 0.0142 | 0.0109 | 0.0089 |

| 32 | 0.0097 | 0.0134 | 0.0102 | 0.008 |

| 33 | 0.009 | 0.0094 | 0.0071 | |

| 34 | 0.0082 | 0.0086 | 0.0063 | |

| 35 | 0.0075 | 0.0078 | 0.0056 | |

| 36 | 0.0067 | 0.007 | 0.005 | |

| 37 | 0.0064 | 0.0066 | 0.00445 | |

| 38 | 0.0067 | 0.0062 | 0.00396 |

The above is the sheet metal specification and thickness table. If you require sheet metal machining services, feel free to reach out to Richconn. We specialize in sheet metal processing and can assist with your specific needs.

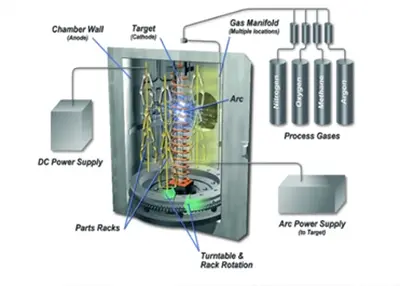

Explain 5 Common Electroplating ProcessesOctober 24, 2022In mechanical design, electroplating is one of our most common surface treatment processes for parts. Today we will take a look at 5 commonly used electroplating processes. There are many methods of e...view

Explain 5 Common Electroplating ProcessesOctober 24, 2022In mechanical design, electroplating is one of our most common surface treatment processes for parts. Today we will take a look at 5 commonly used electroplating processes. There are many methods of e...view What are the characteristics of aerospace parts processingNovember 16, 2023The aerospace industry has always been one of the pinnacles of technology and engineering, and it relies on precision-manufactured aerospace parts to ensure highly reliable and safe aviation and space systems.view

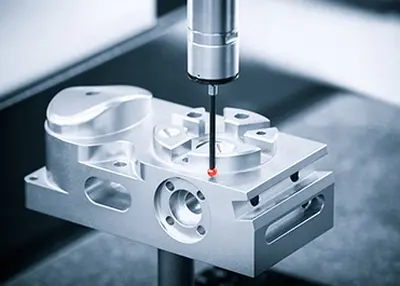

What are the characteristics of aerospace parts processingNovember 16, 2023The aerospace industry has always been one of the pinnacles of technology and engineering, and it relies on precision-manufactured aerospace parts to ensure highly reliable and safe aviation and space systems.view Analysis of Process Characteristics for CNC Machining PartsApril 4, 2023Choose the appropriate machine tool based on the material, contour shape, machining accuracy and other factors of the processed workpiece. Develop a machining plan, determine the processing sequence o...view

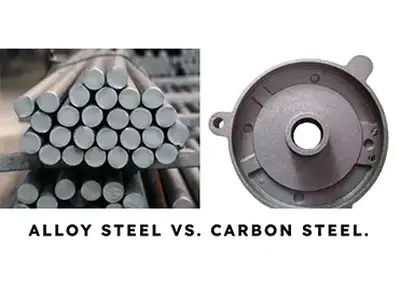

Analysis of Process Characteristics for CNC Machining PartsApril 4, 2023Choose the appropriate machine tool based on the material, contour shape, machining accuracy and other factors of the processed workpiece. Develop a machining plan, determine the processing sequence o...view Alloy Steel vs Carbon Steel: What are the Differences and Advantages?November 27, 2023Steel is one of the most widely used materials in various industries, such as construction, automotive, aerospace, and manufacturing. Steel is an alloy of iron and carbon, but it can also contain other elements to enhance its properties and performance.view

Alloy Steel vs Carbon Steel: What are the Differences and Advantages?November 27, 2023Steel is one of the most widely used materials in various industries, such as construction, automotive, aerospace, and manufacturing. Steel is an alloy of iron and carbon, but it can also contain other elements to enhance its properties and performance.view 4140 vs 4130 Steel: A Comparison of Two Common Alloy SteelsNovember 27, 2023Steel is one of the most widely used materials in various industries, such as construction, automotive, aerospace, and manufacturing. Steel has many types and grades, each with different chemical compositions and mechanical properties.view

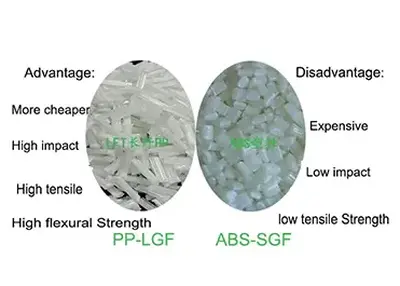

4140 vs 4130 Steel: A Comparison of Two Common Alloy SteelsNovember 27, 2023Steel is one of the most widely used materials in various industries, such as construction, automotive, aerospace, and manufacturing. Steel has many types and grades, each with different chemical compositions and mechanical properties.view ABS vs. Polypropylene (PP): A Comparison of Two Common PlasticsNovember 28, 2023Plastics are widely used materials in various industries, such as packaging, automotive, medical, and consumer products. Plastics are synthetic or semi-synthetic polymers that can be molded or shaped into different forms and products. There are many types and grades of plastics, each with different chemical compositions and physical properties.view

ABS vs. Polypropylene (PP): A Comparison of Two Common PlasticsNovember 28, 2023Plastics are widely used materials in various industries, such as packaging, automotive, medical, and consumer products. Plastics are synthetic or semi-synthetic polymers that can be molded or shaped into different forms and products. There are many types and grades of plastics, each with different chemical compositions and physical properties.view

EN

EN

ru

ru