The medical industry is constantly innovating and finding ways to improve the quality of life and outcomes for patients. One such technology, computer numerical control (CNC) machining, has become a revolutionary tool in medical hardware manufacturing. In this rapidly evolving field, CNC machines not only provide a high level of precision and accuracy, but are also able to cope with a wide range of materials and complex geometries. In this article, we will explore seven key applications in the field of medical CNC machining, from hip replacements to dental tools, that have revolutionized the manufacturing and customization of medical hardware. Let's take a deeper dive into these exciting application areas.

Like any other machined medical hardware, body implants (such as knee implants and hip replacements) require a high level of precision and accuracy. The life and well-being of a patient can be significantly affected by minor errors in the manufacturing process.

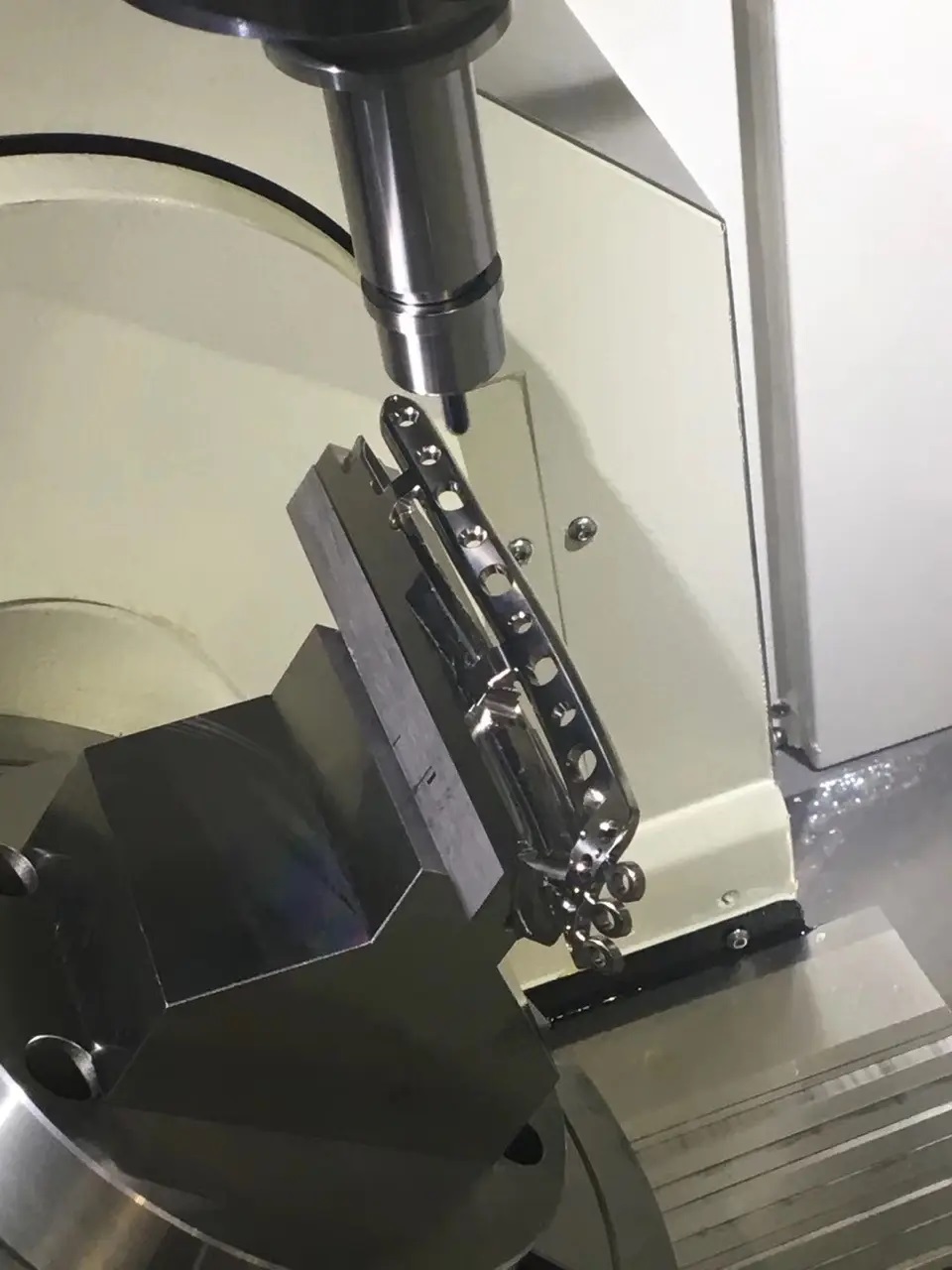

Swiss CNC machines help to accurately manufacture patient-specific parts while achieving tolerances as small as 4 μm. a CNC machining center receives a request from an orthopedic surgeon, creates a CAD model, and recreates the body part using reverse engineering and CNC technology.

The medical industry requires these implants to be made from biocompatible materials such as PEEK and titanium. These materials are challenging to machine - they generate excessive heat during machining and the use of coolants is often prohibited due to concerns about contamination. CNC machines are helping to solve this challenge because they have compatibility with a wide range of materials.

Complex surgical procedures require high-precision, specialized tools. These instruments range from simple scalpels and scissors to complex robotic arms for minimally invasive surgery. These tools must be manufactured with high precision. cnc machining plays a vital role in the production of surgical tools required for various medical procedures.

CNC machines can achieve complex geometries and tight tolerances, making them ideal for producing complex surgical tool designs. For example, robotic-assisted surgical instruments can be machined using CNC technology to ensure the highest level of precision, enabling surgeons to perform complex surgeries with greater accuracy and fewer complications.

Many medical devices (such as MRI scanners, heart rate monitors and X-ray machines) are equipped with thousands of CNC-machined electronic components. Examples include switches, buttons and levers, as well as electronic housings and enclosures.

Unlike implants and surgical tools, these medical devices do not need to be biocompatible because they do not come into direct contact with the patient's internal systems. However, the manufacture of these parts is still largely overseen and controlled by multiple regulatory agencies.

Failure to comply with the standards set by these regulatory bodies can result in significant fines (and sometimes even imprisonment) for machine shops. There have also been cases where medical professionals involved have had their licenses to practice medicine revoked. Therefore, it is important that you choose your medical device manufacturer wisely.

Personalization is becoming increasingly important in healthcare, and this is most evident in the field of prosthetics. Patients need a prosthetic device that fits their body perfectly, and traditional mass production techniques are often unable to meet the needs of patients, Custom Manufacturing can help you solve this problem.

cnc machining is transforming the field of prosthetics by producing customized devices based on each patient's unique physiology. cnc machines use 3D scanning and CAD modeling to create prosthetics with intricate detail and high-precision dimensions, ensuring optimal function and comfort for patients.

Using CNC technology, prosthetics can be produced with high precision to ensure comfort and full functionality.

Orthopedic devices such as plates, screws and rods are widely used in the medical field to repair or replace damaged bones and joints. Given the critical role these devices play in patient rehabilitation, it is imperative that they are manufactured with the highest level of precision and quality.

cnc machining plays a vital role in the production of these orthopedic devices. cnc technology is ideally suited for the production of these devices as it is capable of machining complex geometries with high precision. In addition, cnc machining can handle a wide range of biocompatible materials, including titanium and stainless steel, which are commonly used in orthopedic devices.

Creating prototypes for testing and validation is critical before mass production of any medical device, and Richconn's CNC machining offers a fast and cost-effective solution for producing medical device prototypes, whether it's a medical CNC turning service or a CNC milling service, we've got you covered. With the ability to quickly generate multiple iterations of a design, engineers can test and refine the device to ensure it is safe, effective and meets regulatory requirements.

This capability is critical in the fast-paced world of medical device development, where the ability to quickly bring a new product to market can be a significant competitive advantage. cnc machining also allows for the production of low-volume prototypes, enabling manufacturers to minimize waste and save on material costs during the development process.

cnc machining is critical to providing high quality dental care through the creation of customized dental tools and implants abutment. Dentists around the world rely on advanced CNC technology for precise treatment. This technology is ideally suited for the manufacture of durable instruments such as drills, scalers, probes, and forceps, which are essential for a variety of procedures.

Producing these instruments requires superior durability to withstand sterilization while ensuring patient safety.CNC manufacturing provides repeatability and stringent quality control, guaranteeing that each tool meets exacting standards.

Dental implants provide a long-term solution for missing teeth and require precise customization using precision CNC machining. These implants are created based on digital scans, ensuring an accurate and personalized fit for each patient. cnc machining has revolutionized the fabrication of dental restorations, improving treatment outcomes.

By effectively utilizing materials such as titanium and zirconia, CNC technology enables precise modifications with superior efficiency and results.

Metal Drill Bits Guide: Choosing the Right Tool for the JobSeptember 25, 2023I will walk you through everything you need to know about metal drill bits, from understanding their types to making the right choice for your specific needs.view

Metal Drill Bits Guide: Choosing the Right Tool for the JobSeptember 25, 2023I will walk you through everything you need to know about metal drill bits, from understanding their types to making the right choice for your specific needs.view Titanium vs Stainless Steel: Choosing the Right Material for Your MachiningNovember 24, 2023Understand the differences between titanium and stainless steel and choose the best material for CNC machining.view

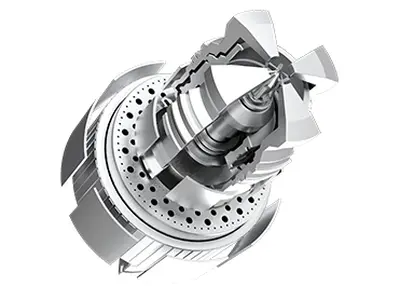

Titanium vs Stainless Steel: Choosing the Right Material for Your MachiningNovember 24, 2023Understand the differences between titanium and stainless steel and choose the best material for CNC machining.view Unlocking Precision: Exploring the Parts of a CNC MachineSeptember 22, 2023Are you ready to dive into the world of CNC (Computer Numerical Control) machines? If you're fascinated by precision engineering and the wonders it can achieve, you've come to the right place.view

Unlocking Precision: Exploring the Parts of a CNC MachineSeptember 22, 2023Are you ready to dive into the world of CNC (Computer Numerical Control) machines? If you're fascinated by precision engineering and the wonders it can achieve, you've come to the right place.view Die Casting Machine: A Detailed ReviewMarch 6, 2024Die casting machines are essential in the manufacturing industry. Let's delve into a detailed review of their key features, benefits, and applications.view

Die Casting Machine: A Detailed ReviewMarch 6, 2024Die casting machines are essential in the manufacturing industry. Let's delve into a detailed review of their key features, benefits, and applications.view The Ultimate Guide to Different Types of Screws 2024January 10, 2024Screws are one of the most common fasteners in the world. Let’s discover various types of screws, materials, and applications. Get tailored excellence in fastening solutions!view

The Ultimate Guide to Different Types of Screws 2024January 10, 2024Screws are one of the most common fasteners in the world. Let’s discover various types of screws, materials, and applications. Get tailored excellence in fastening solutions!view Passivation 101: What Is Passivated Stainless Steel and Is It Necessary?December 8, 2023Passivation enhances stainless steel’s durability and longevity by removing iron and forming a protective film layer. Here’s a basic guide to passivation of stainless steel.view

Passivation 101: What Is Passivated Stainless Steel and Is It Necessary?December 8, 2023Passivation enhances stainless steel’s durability and longevity by removing iron and forming a protective film layer. Here’s a basic guide to passivation of stainless steel.view

EN

EN

ru

ru