Welcome to the realm of precision engineering, where CNC Machined Billet Aluminum takes center stage. As the proud provider of CNC machining services, Richconn stands as your gateway to unrivaled expertise and cutting-edge solutions in the realm of aluminum machining. Let's delve into the intricacies of CNC machining and the unparalleled advantages offered by billet aluminum.

CNC billet is a raw material that is machined on a CNC machine, whose shape and size have been pre-designed in a CNC program and accurately machined by the automated control system of the CNC machine. CNC blanks are widely used in various manufacturing industries, such as aerospace, automotive manufacturing, mold manufacturing, electronic equipment manufacturing and other fields. Its emergence and application, marking the manufacturing industry from the traditional manual operation to the direction of digitalization and automation, to improve production efficiency, product quality and reduce production costs to provide strong support.

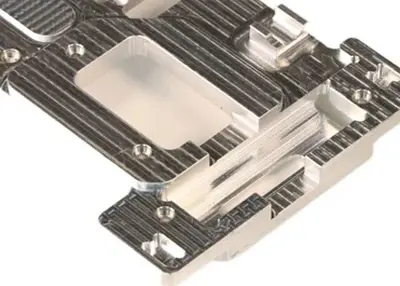

CNC aluminum billet is an aluminum billet that is machined by a computer numerical control (CNC) machine. In this process, the computer numerical control system is responsible for controlling the movement of the machine tool to cut and form the aluminum billet in a precise manner. This manufacturing method is highly automated and precise, and is often used to produce a variety of aluminum products such as parts, spare parts, industrial components, and automotive parts. In CNC aluminum billet machining, pre-designed CNC programs enable precise control of the complex shapes and sizes of aluminum billets, thereby meeting the demand for high-precision aluminum products in a variety of industrial and manufacturing fields.

Aluminum is a lightweight, corrosion-resistant metal with excellent thermal and electrical conductivity. Due to its properties, aluminum is widely used in aviation, automotive, electronics and other fields. In manufacturing, the balance between lightness and strength of aluminum makes it an ideal material.

Aluminum has good machinability and is easy to cut and form. In addition, the mechanical properties of aluminum can be adjusted by heat treatment and other methods to meet different engineering needs.

The machining process of CNC aluminum billet firstly involves the selection of suitable aluminum material. According to the specific applications and requirements, choose different grades and states of aluminum, such as 6061 aluminum, 7075 aluminum, etc..

In the machining of CNC aluminum billet, it is first necessary to design the CNC program. A CNC program is a series of instructions that tell the CNC machine tool how to move, rotate and cut the workpiece. These programs can be generated by CAD (Computer Aided Design) software.

Before machining begins, the operator needs to set various parameters of the CNC machine, including operating speed, depth of cut, and tool selection. The setting of these parameters affects the quality and efficiency of the final machining result.

Once the CNC program and machine parameters are set up, the CNC aluminum billet machining process can begin. the CNC machine moves the tool along the predetermined path according to the predetermined CNC program, and gradually cuts the aluminum billet into the designed shape and size.

During the machining process, inspections are usually carried out to ensure that the machining quality meets the requirements. If necessary, the operator can make corrections to the CNC program based on the inspection results to ensure the accuracy and quality of the final product.

Choosing the right aluminum material for CNC machining is critical because different types of aluminum alloys exhibit different properties in CNC machining, including ease of machining, surface quality, strength, and more.

Characteristics

Strength: 6061 aluminum alloy has high strength and can be used in applications requiring a certain level of strength and hardness.

Corrosion resistance: good corrosion resistance, suitable for use in wet or corrosive environments.

Weldability: Easily welded and suitable for applications requiring welding.

Machinability: 6061 aluminum alloy is sensitive to heat treatment and is easily CNC machined.

Areas of Application

Aerospace: Used for aircraft components such as wings and boat tails.

Automotive: For automotive components such as body structures and engine parts.

Electronic equipment: for the manufacture of radiators and other electronic equipment parts.

Properties

High Strength: 7075 Aluminum Alloy is a high-strength aluminum alloy, usually used in applications requiring high strength.

Hardness: High hardness for applications requiring higher hardness.

Fatigue Resistance: Good fatigue resistance, suitable for parts that are subjected to cyclic loading.

Areas of Application

Aerospace: Used in the manufacture of aircraft structural components such as wings and landing gear.

Military: Due to its high strength and hardness, it is commonly used in the manufacture of military equipment and weapon parts.

Sports equipment: Used in the manufacture of demanding sports equipment, such as mountaineering equipment and bicycle parts.

Properties

Machinability: 6063 aluminum alloy is easy to process, suitable for a variety of CNC machining processes.

Good thermal conductivity: Good thermal conductivity for applications requiring heat dissipation properties.

Corrosion Resistance: It has a certain degree of corrosion resistance and is suitable for applications in some corrosive environments.

Areas of application

Construction and building materials: used in the manufacture of windows, door frames and building structures.

Electronic equipment: for the manufacture of shells, radiators and other electronic equipment parts.

Transportation: used to manufacture bicycle frames and other transportation parts.

Characteristics

Good plasticity: 5052 aluminum alloy has good plasticity, suitable for complex shapes of CNC machining.

Fatigue resistance: good fatigue resistance, suitable for parts requiring fatigue resistance.

Corrosion resistance: good corrosion resistance, suitable for applications in wet or corrosive environments.

Areas of application

Shipbuilding: used in the manufacture of hulls, bridges and other components.

Food processing equipment: due to its good corrosion resistance, suitable for the manufacture of food processing equipment parts.

Automobile parts: used in the manufacture of automobile body panels, fuel tanks and other parts.

Hardness is an important consideration when selecting aluminum alloys for CNC machining. Harder aluminum alloys may result in faster tool wear during CNC machining and therefore require more frequent tool changes. However, hardness is also related to the strength and wear resistance of aluminum alloys, and proper hardness can improve the durability of parts.

Billet aluminum is highly sought after in manufacturing and fabrication because of its superior set of properties and attributes that make it ideal for a wide range of applications. From aerospace to automotive manufacturing, from electronic devices to building structures, billet aluminum has demonstrated superior performance in a variety of areas. Here is a detailed explanation of why billet aluminum is better:

Aluminum is a lightweight metal with a relatively low density, about 1/3 that of iron. despite its lightness, aluminum alloys exhibit excellent strength, especially some high-strength aluminum alloys such as 7075. this makes billet very popular in applications where overall weight needs to be reduced but strength is required, such as aerospace and automotive manufacturing. The lightweight and high strength properties help to improve product performance, lighten loads, reduce energy consumption, and make manufacturing more efficient.

Billet aluminum has superior corrosion resistance due to the fact that aluminum reacts with oxygen to form an alumina layer, which forms a protective film that prevents further oxidation. This makes billet aluminum particularly suitable for applications that require long-term exposure to wet or corrosive environments, such as marine engineering, building structures and automotive components.

Aluminum is a good thermal conductor and has better thermal conductivity than many other metals. This makes billet aluminum excel in applications that require heat dissipation, such as electronic equipment heat sinks, engine components and industrial equipment. The superior thermal conductivity helps to effectively disperse and transfer heat, keeping equipment operating in the proper temperature range.

Billet aluminum excels in machining processes, especially in numerically controlled machining (CNC). It has a low melting point and is easy to cut and shape. This machinability makes billet aluminum an ideal material for parts of all shapes and sizes, and the high precision and flexibility of CNC machining allows billet aluminum to be adapted to different design requirements, increasing productivity.

Aluminum is a recyclable metal. Recycling aluminum uses much less energy than extracting the metal from ore. This gives aluminum billets a clear advantage in terms of sustainability and environmental protection. Recycling aluminum not only helps to reduce the waste of resources, but also helps to reduce carbon dioxide emissions, which is in line with the modern society's pursuit of environmental protection and sustainable development.

Aluminum billet has good surface treatment properties and can withstand various surface treatment methods, such as anodization, spraying and electrophoretic coating. This provides a wider range of appearance options and opportunities to improve surface durability. Whether you are looking for corrosion resistance or aesthetic appearance, billet aluminum offers a flexible solution.

Aluminum billet is relatively inexpensive to produce compared to some other metals. Aluminum ores are relatively abundant and the cost of refining and manufacturing is relatively low. In addition, the lightweight and high strength properties of billet mean that in some applications less material can be used, thus reducing overall manufacturing costs.

Due to its many superior properties, billet aluminum is used in a wide variety of applications. Aluminum billets can be found in aerospace, automotive manufacturing, electronic equipment, building structures, industrial manufacturing, and more. Its versatility and adaptability make it the material of choice in many industries.

In practical applications, the demand for aluminum billet is increasing, driving the development of related technologies. Driven by new materials, processes and technologies, aluminum billet will continue to play its unique advantages, bringing more innovation and progress to manufacturing in various fields.

Understanding Steel Material for Custom Prototyping: Properties, Grades, and ApplicationsMarch 14, 2024Let’s explore the diverse properties, grades and uses of steel material in prototyping, from its melting point to its versatility across different industry sectors.view

Understanding Steel Material for Custom Prototyping: Properties, Grades, and ApplicationsMarch 14, 2024Let’s explore the diverse properties, grades and uses of steel material in prototyping, from its melting point to its versatility across different industry sectors.view What kind of process is suitable for machining different types of parts?October 31, 2023Machining is a widely used manufacturing process and is one of the common machining methods used in the manufacturing industry for making different types of parts. Different types of parts require dif...view

What kind of process is suitable for machining different types of parts?October 31, 2023Machining is a widely used manufacturing process and is one of the common machining methods used in the manufacturing industry for making different types of parts. Different types of parts require dif...view Anodized Aluminum: How to Anodize Aluminum Parts?January 23, 2024Are you familiar with anodizing aluminum? If not, you can read this article and get to know about the process and other related things.view

Anodized Aluminum: How to Anodize Aluminum Parts?January 23, 2024Are you familiar with anodizing aluminum? If not, you can read this article and get to know about the process and other related things.view From Blueprint to Reality: The Role of 3D Printing in ArchitectureOctober 10, 2023The architecture industry is undergoing profound change thanks to 3D printing. Architects are harnessing this technology to revolutionize the way they design, construct and experience buildings. With 3D printing, architects can transform digital designs into tangible objects, opening up endless possibilities.view

From Blueprint to Reality: The Role of 3D Printing in ArchitectureOctober 10, 2023The architecture industry is undergoing profound change thanks to 3D printing. Architects are harnessing this technology to revolutionize the way they design, construct and experience buildings. With 3D printing, architects can transform digital designs into tangible objects, opening up endless possibilities.view What Is CNC Machining? The Basic Information You Need to KnowMarch 27, 2024What is CNC machining? Here is the basic information that you must know, such as its advantages, disadvantages, applications, and so on.view

What Is CNC Machining? The Basic Information You Need to KnowMarch 27, 2024What is CNC machining? Here is the basic information that you must know, such as its advantages, disadvantages, applications, and so on.view The Application of CNC Machining in Mechanical Equipment - SheetMay 7, 2024Let’s explore the world of sheet in mechanical equipment! Read this article to discover its importance, applications, manufacturing processes, and more.view

The Application of CNC Machining in Mechanical Equipment - SheetMay 7, 2024Let’s explore the world of sheet in mechanical equipment! Read this article to discover its importance, applications, manufacturing processes, and more.view

EN

EN

ru

ru