Injection molding is a widely used manufacturing process for the production of components and products. As with any manufacturing process, it is crucial to understand the cost factors involved in injection molding.

So is the cost of injection molding higher? What are the factors affecting injection molding costs? How do you reduce costs in injection molding for your project? Keep reading as we will provide answers to the above questions about injection molding costs.

Injection molding can be expensive, especially when considering the upfront costs involved in designing and manufacturing the molds. However, once the molds are created, the actual production of parts through injection molding can be relatively cost-effective and efficient. It allows for high-volume production and can produce parts with consistent quality and precision. The overall cost of injection molding also depends on various factors such as material selection, tooling costs, labor charges, and manufacturing volume.

This is a pretty wide price range. The exact cost fluctuates based on several elements involved in the injection molding process. Here are the top 5 factors you need to pay attention to:

Component Size

The size of the component being produced through injection molding can affect the cost. Larger parts require a larger injection molding machine to produce the large mold size to hold such parts. Additionally, larger components may require more material in molding injecting, which in turn influences the cost of molding injection.

Component Complexity

The complexity of the parts design affects the complexity of the mold required for the injection molding process, such as OEM CNC machining, EDM machining, or 3D printing. Complex components with intricate designs or features may require more intricate and specialized molds, leading to higher manufacturing costs.

The cost of raw materials significantly affects injection molding expenses. Material selection in injection molding also depends on manufacturing preference. Although most will use aluminum materials due to their formability, technical expertise comes into play. However, the producer prefers a steel mold, even if it is more expensive. mold damage might raise the cost of production because steel molds are difficult to repair.

The tooling cost for different manufacturing processes, such as 3D printing, CNC machining, and EDM machining, can vary significantly and can affect the injection mold cost in several ways. Here's a breakdown of these processes and their impact on mold cost:

3D Printing

The cost of tooling for 3D printing is relatively low compared to other processes. It typically involves designing and printing plastic or metal parts directly without the need for traditional tooling like molds. Therefore, 3D printing can be a more cost-effective solution for lower production volumes or prototyping.

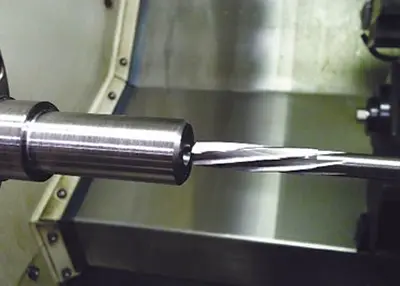

CNC Machining

CNC machining involves using computer-controlled machines to remove material from a solid block to create the desired shape. The process can be moderate for making injection molds with intricate and complex designs. CNC machining is suitable for producing steel and aluminum materials in an accurate molding manufacturing process, and it can be more cost-effective for medium production volumes.

EDM Machining

Electrical Discharge Machining (EDM) is a precision machining process that uses electrical sparks to shape metal parts. EDM tooling costs can be higher compared to other processes due to the specialized equipment required. It is commonly used for complex shapes or hardened materials that are difficult to machine using traditional methods.

The labor costs associated with injection molding primarily include the wages of skilled workers involved in setting up and operating the machinery, as well as any additional labor required for post-processing or assembly. Depending on the location and skill level of the workers, labor costs can vary significantly. Higher labor costs can contribute to higher mold costs because the labor-intensive nature of injection molding requires skilled operators and technicians.

The production volume is indeed a significant factor in injection molding costs, and it can be categorized into the following main categories:

Low-volume Production

The injection molding cost for low-volume production is typically higher on a per-unit basis because the fixed costs associated with mold creation and setup are spread over a smaller number of units. The use of simpler molds and less sophisticated machines may also be more common in low-volume production.

Medium-volume Production & High-volume Production

This involves highly efficient and automated production processes, including the use of advanced injection molding machines and complex molds. The per-unit cost of injection molding in medium-volume or high-volume production is usually low due to the economies of scale. The fixed costs are distributed across a much larger number of units, resulting in lower production costs per unit.

There are several ways to reduce costs in injection molding. Here are some tips that can consider:

Analyze the part design and identify any features that are unnecessary or could be simplified. Complex features or tight tolerances may require additional machining or more expensive molds.

Material choice can significantly impact the overall cost of injection molding. Consideration should be given to selecting a material that meets the required mechanical properties while being cost-effective.

If you have a recurring production need, reusing molds for subsequent production runs can be cost-effective. This eliminates the initial cost of mold creation, and the amortized cost per unit decreases with each production run. However, it's important to ensure that the mold is in good condition and still within its lifespan for producing quality parts.

By selecting appropriate injection molding services, you can obtain both high-quality injection molded parts and a cost-effective process. Richconn provides custom injection molding services to assist you in creating various prototypes or genuine parts based on what you need.

▶ Here are some benefits you can get from Richconn.

Richconn offers a comprehensive portfolio of CNC machining materials and seriously evaluates them based on their cost-effectiveness.

Richconn has the ability to simplify the mold design without affecting functionality and lowering the requirements of the parts.

Richconn, as a reliable partner, helps you better handle the complete surface finishing process, including anodizing, polishing, PVD coating, powder coating, plating, etc. Richconn can offer surface finishing, which increases parts' aesthetic appeal or functionality after molding injection.

Richconn introduces the latest CNC machines with an accuracy of 0.003mm, imported from Japan FANUC. It firmly aims to ensure precise and efficient injection molding.

After reading this article, you will have a better understanding of the cost of injection molding and how it differs from project to project. Are you considering employing injection molding for your next project? Then send the request to Richconn at our contact email, and our team will respond with the best price available for your needs.

Do You Know How Anodizing Works?November 4, 2022Anodizing, the process of forming an oxide film on aluminum products (anode) under the action of an applied current under the corresponding electrolyte and specific process conditions of metal or allo...view

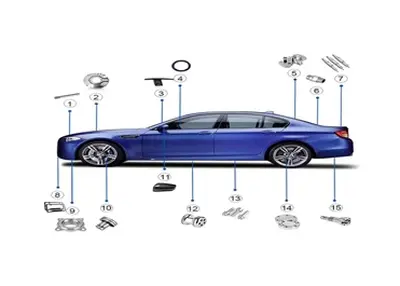

Do You Know How Anodizing Works?November 4, 2022Anodizing, the process of forming an oxide film on aluminum products (anode) under the action of an applied current under the corresponding electrolyte and specific process conditions of metal or allo...view The Precision of CNC Automotive Parts in Gear SystemsJanuary 5, 2024In the world of automotive manufacturing, precision and reliability are crucial for the smooth operation of gear systems. As technology advances, the demand for precision components in the automotive ...view

The Precision of CNC Automotive Parts in Gear SystemsJanuary 5, 2024In the world of automotive manufacturing, precision and reliability are crucial for the smooth operation of gear systems. As technology advances, the demand for precision components in the automotive ...view Material Selection for Stereolithography (SLA) 3D PrintingOctober 17, 2023When comparing the material properties of thermoplastics used in injection molding with "thermoplastic-like" materials used in an industrial 3D printing technology such as stereolithography (SLA), many factors come into play.view

Material Selection for Stereolithography (SLA) 3D PrintingOctober 17, 2023When comparing the material properties of thermoplastics used in injection molding with "thermoplastic-like" materials used in an industrial 3D printing technology such as stereolithography (SLA), many factors come into play.view An Ultimate Guide to Medical Device ManufacturingMarch 13, 2024Nowadays, manufacturing medical devices is becoming more and more important. This article will let you know more about medical device manufacturing.view

An Ultimate Guide to Medical Device ManufacturingMarch 13, 2024Nowadays, manufacturing medical devices is becoming more and more important. This article will let you know more about medical device manufacturing.view What Are the Precautions for EDM Machining?October 27, 2023EDM is a relatively new metal working technique compared to rotary tooling, shearing and forging. A fast pulsed high-voltage discharge (spark) passes through the gap between the electrode and the grounded workpiece, removing material from the workpiece by erosion.view

What Are the Precautions for EDM Machining?October 27, 2023EDM is a relatively new metal working technique compared to rotary tooling, shearing and forging. A fast pulsed high-voltage discharge (spark) passes through the gap between the electrode and the grounded workpiece, removing material from the workpiece by erosion.view How to Reduce the Cost of CNC Machined Parts Through Structural DesignOctober 20, 2023CNC machined parts, i.e. parts processed by CNC equipment, CNC machining, usually refers to the precision machining method digitally controlled by a computer, which has become a common method of machining in nowadays.view

How to Reduce the Cost of CNC Machined Parts Through Structural DesignOctober 20, 2023CNC machined parts, i.e. parts processed by CNC equipment, CNC machining, usually refers to the precision machining method digitally controlled by a computer, which has become a common method of machining in nowadays.view

EN

EN

ru

ru