Have you ever wondered about the remarkable process that transforms ordinary steel into a corrosion-resistant wonder material? Look no further, as we embark on an enlightening journey to understand the world of galvanization. In this article, I will unravel the secrets behind galvanized materials, providing you with insights, comparisons, and a roadmap to harness their potential.

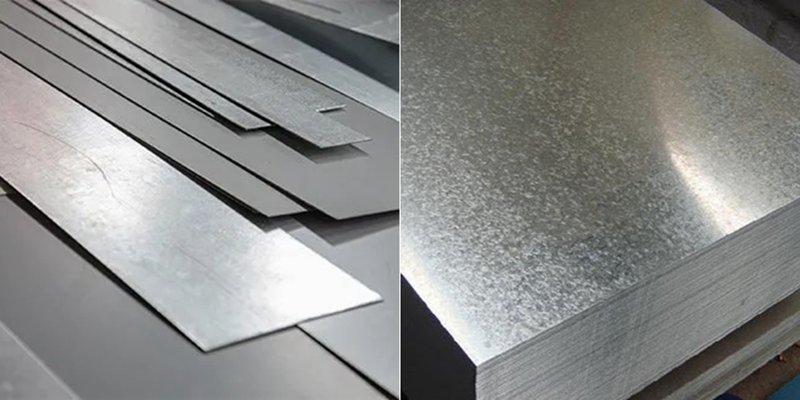

Galvanization, in essence, is the process of coating steel or iron with a protective layer of zinc. Galvanizing is a form of metal surface finishing.This coating forms a barrier that shields the underlying metal from rust and corrosion, making it exceptionally durable in harsh environments. But why is this process so important?

Galvanization has been a game-changer in numerous industries, from construction to agriculture, thanks to its ability to extend the lifespan of materials and reduce maintenance costs. Understanding its definition is the first step towards appreciating its significance.

Galvanized pipes, a common application of galvanization, are steel pipes coated with a layer of zinc. The manufacturing process involves immersing the steel in a bath of molten zinc, creating a metallurgical bond. This results in pipes that are not only rust-resistant but also suitable for transporting water and other fluids.

However, it's essential to note that galvanized pipes have their drawbacks, including potential zinc leaching into the water. Therefore, when considering their use, it's vital to weigh the pros and cons carefully.

The term "galvanize" finds its origins in the name of Luigi Galvani, an Italian scientist renowned for his work on the effects of electricity on muscles. Ironically, galvanization has nothing to do with electricity, but the name stuck due to its transformative nature.

When you think of galvanization, picture it as electrifying steel with a protective shield against corrosion. This historical context adds a layer of intrigue to an otherwise industrial process.

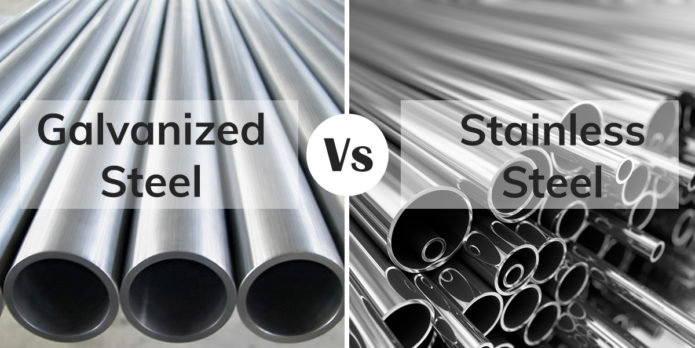

Now, let's delve into the intriguing comparison between galvanized and stainless steel. Galvanized steel, as we know, boasts corrosion resistance through its zinc coating. On the other hand, stainless steel relies on its intrinsic properties, primarily chromium, to fend off corrosion.

The choice between these materials depends on the specific requirements of your project. Galvanized steel is cost-effective and suitable for outdoor applications, while stainless steel shines in environments demanding exceptional corrosion resistance.

Strength matters, and when it comes to galvanized and stainless steel, there's much to consider. Galvanized steel's strength is commendable, but stainless steel outperforms it in terms of tensile strength and impact resistance.

If you're facing high-stress scenarios or need materials for structural purposes, stainless steel is your go-to choice. However, for many applications, galvanized steel's strength is more than sufficient.

Galvanized materials find their way into a myriad of industries. In construction, they form the backbone of structures, enduring the elements. In the automotive sector, they protect crucial components from rust. Agriculture relies on galvanized equipment to withstand exposure to soil and moisture.

To harness the full potential of galvanized materials, identify the industry-specific applications and leverage their durability to your advantage.

As responsible stewards of the environment, we must address the impact of galvanization. The process, while essential, has raised environmental concerns due to zinc emissions and energy consumption.

To mitigate these issues, efforts are underway to develop more sustainable galvanization methods and promote recycling. Embracing these eco-friendly approaches ensures that we protect both our projects and our planet.

The world of galvanization is not static; it evolves. Emerging technologies promise more efficient and environmentally friendly galvanization methods. These advancements will further enhance the durability and sustainability of galvanized materials.

Stay ahead of the curve by keeping an eye on these trends, and be ready to embrace innovations that will redefine how we utilize galvanized materials.

In this second section, we delve deeper into the industrial applications of galvanized materials and explore the specific advantages they offer in various sectors. Moreover, we introduce Richconn, a prominent Chinese CNC machining service company, highlighting their contributions to galvanized materials in the industry.

In the construction industry, durability and longevity are paramount. Galvanized materials are the unsung heroes of construction projects. They provide structural integrity while withstanding the harshest environmental conditions.

Advantages of Galvanized Materials in Construction

Corrosion Resistance: Galvanized steel helps buildings endure rain, snow, and humidity without succumbing to rust.

Low Maintenance: Reduced maintenance costs mean more significant savings over the long term.

Sustainability: Galvanized steel is recyclable, contributing to environmentally friendly construction practices.

In the automotive sector, precision and reliability are non-negotiable. Galvanized materials play a vital role in ensuring the longevity of vehicles, particularly in challenging weather conditions.

Advantages of Galvanized Materials in Automotive Manufacturing

Rust Prevention: Galvanized parts protect critical components, ensuring the safety and functionality of vehicles.

Longevity: Galvanized steel parts have a longer lifespan, reducing the need for replacements.

Cost Efficiency: Lower maintenance and replacement costs benefit both manufacturers and consumers.

Agriculture demands rugged equipment that can withstand exposure to soil, water, and varying weather conditions. Galvanized materials excel in this demanding industry.

Advantages of Galvanized Materials in Agriculture

Resistance to Soil Corrosion: Galvanized equipment remains corrosion-free despite contact with soil and fertilizers.

Durability: Agricultural machinery lasts longer, reducing downtime and maintenance costs.

Hygiene: Galvanized surfaces are easy to clean and maintain, ensuring the integrity of food production.

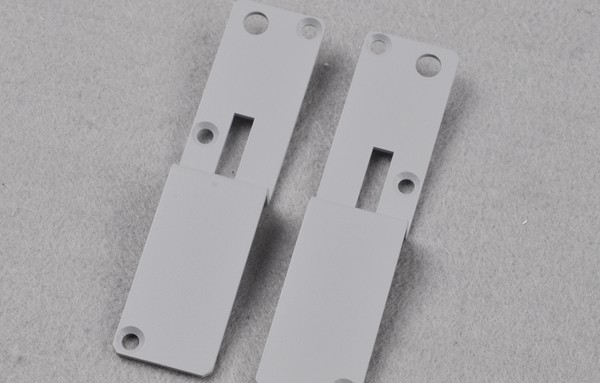

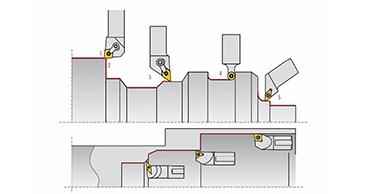

Richconn, a leading Chinese CNC machining service company, has played a pivotal role in integrating galvanized materials into various industries. They specialize in precision machining of galvanized components, offering bespoke solutions to meet the specific needs of their clients.

Richconn's Contributions to Galvanized Materials

Precision Machining: Richconn's state-of-the-art CNC machining capabilities ensure the accuracy and quality of galvanized components.

Customization: They collaborate closely with clients to develop tailor-made solutions, optimizing the performance of galvanized materials.

Quality Assurance: Richconn's commitment to quality control guarantees the reliability of Plating components in critical applications.

The synergy between industries and companies like Richconn drives innovation in galvanized materials. As we look ahead, we anticipate even more sophisticated applications and sustainable solutions, further solidifying galvanization's role in shaping our world.

In this section, we delve into the environmental aspects of galvanization and the ongoing efforts to make the process more sustainable. We'll explore the ecological footprint of galvanized materials and discuss the crucial role that sustainability plays in shaping the future of this industry.

While galvanization provides remarkable corrosion resistance, it's essential to acknowledge its environmental footprint. The process involves the use of zinc, which, if not managed properly, can have negative consequences.

Environmental Considerations in Galvanization

Zinc Emissions: Galvanization can release zinc emissions into the air and water, impacting ecosystems.

Energy Consumption: The energy required for galvanization contributes to carbon emissions.

To address these environmental concerns, researchers and industry leaders are actively exploring sustainable galvanization methods that reduce the environmental impact.

Promising Sustainable Galvanization Approaches

Zinc Recycling: Recycling zinc from galvanized materials reduces the demand for new zinc production.

Alternative Coating Materials: Research into alternative, eco-friendly coatings that offer corrosion resistance without zinc.

Energy Efficiency: Improving the energy efficiency of galvanization processes reduces carbon emissions.

The push for sustainability in galvanization aligns with broader global efforts to reduce the environmental impact of various industries. Galvanized materials can contribute to sustainability in multiple ways.

The Role of Galvanized Materials in Sustainability

Longevity: The durability of galvanized materials reduces the need for frequent replacements, conserving resources.

Recyclability: Galvanized steel is highly recyclable, reducing waste and the need for new raw materials.

Corrosion Prevention: Protecting infrastructure and equipment from corrosion extends their lifespan, minimizing resource consumption.

As sustainability becomes an increasingly critical factor in industry decisions, the future of galvanization relies on its ability to adapt. Companies like Richconn, with their commitment to sustainable practices, are at the forefront of this transformation.

Richconn, as a prominent player in CNC machining services, recognizes the importance of sustainability. They are actively working towards integrating sustainable galvanization practices into their operations.

Richconn's Sustainability Initiatives

Efficient Resource Utilization: Richconn aims to minimize waste and resource consumption in their CNC machining processes.

Green Energy: They explore the use of renewable energy sources to power their operations.

Eco-Friendly Coatings: Richconn investigates alternative, environmentally friendly coatings for galvanized components.

The synergy between galvanized materials, sustainable practices, and innovative companies like Richconn sets the stage for a greener and more sustainable future. By embracing sustainability, we can continue to benefit from the strength and durability of galvanized materials while minimizing their environmental impact.

In this final section, we explore the future trends and innovations in the world of galvanized materials. We delve into emerging technologies that promise to redefine galvanization, making it more efficient, cost-effective, and environmentally friendly.

The field of galvanization is ripe for innovation, and emerging technologies are poised to revolutionize the industry.

Promising Technologies in Galvanization

Nano-Coatings: Nano-scale coatings offer enhanced corrosion protection with minimal material usage.

Plasma Electrolytic Oxidation: A new electrochemical process that provides excellent corrosion resistance.

Galvanic Paints: Advanced paints that mimic the galvanization process, offering an alternative to traditional methods.

The future holds exciting possibilities for galvanized materials, driven by continuous research and development.

Future Advancements in Galvanized Materials

Improved Coating Thickness Control: Precision control of zinc coating thickness for customized corrosion protection.

Multi-Material Galvanization: Coating various materials, including plastics, with zinc for versatile applications.

Smart Galvanized Materials: Integration of sensors and monitoring systems for real-time corrosion detection.

The evolving landscape of galvanization presents opportunities for industries to embrace innovation and sustainability. As we look to the future, we must remain vigilant in adopting these advancements to maximize the benefits of galvanized materials.

In conclusion, galvanized materials have a rich history, a vital role in various industries, and a promising future shaped by sustainability and innovation. Companies like Richconn are pivotal in driving these changes, making galvanized materials stronger, more durable, and environmentally friendly.

By understanding the nuances of galvanization, its applications, and its impact on the environment, we can make informed decisions that benefit our projects, our industries, and the planet. As you continue to explore the world of galvanized materials, remember that knowledge and sustainability go hand in hand, paving the way for a brighter and more durable future.

Dual-tone Baking Paint Technology: Achieving Unique Visual EffectsJuly 31, 2023Have you seen two-tone colored cars, phones, appliances, buildings? Want to understand how to achieve two-tone baked paint? This article introduces this unique parts painting technique in detail, expl...view

Dual-tone Baking Paint Technology: Achieving Unique Visual EffectsJuly 31, 2023Have you seen two-tone colored cars, phones, appliances, buildings? Want to understand how to achieve two-tone baked paint? This article introduces this unique parts painting technique in detail, expl...view Unveiling the Precision World of Machined Gears: A Richconn PerspectiveNovember 10, 2023In the intricate tapestry of mechanical engineering, machined gears stand as the unsung heroes, translating rotational motion with unparalleled precision. These gears are meticulously crafted to meet the demanding requirements of various industries, ensuring seamless operation in complex machinery.view

Unveiling the Precision World of Machined Gears: A Richconn PerspectiveNovember 10, 2023In the intricate tapestry of mechanical engineering, machined gears stand as the unsung heroes, translating rotational motion with unparalleled precision. These gears are meticulously crafted to meet the demanding requirements of various industries, ensuring seamless operation in complex machinery.view American Scientific Research Has Found A Fast And Effective Processing Method Of Low-Temperature Titanium AlloyMay 30, 2022Titanium is widely used in the aerospace industry because of its high strength and low density. However, compared with steel, aluminum, and other metals, its hot processing cost is high and it is at a...view

American Scientific Research Has Found A Fast And Effective Processing Method Of Low-Temperature Titanium AlloyMay 30, 2022Titanium is widely used in the aerospace industry because of its high strength and low density. However, compared with steel, aluminum, and other metals, its hot processing cost is high and it is at a...view Cutting Costs, Not Quality: Exploring the Best Cheap CNC Material OptionsDecember 4, 2023In today's competitive market, every business is constantly finding ways to cut costs without compromising the quality of their products or services. When it comes to CNC machining, one of the mos...view

Cutting Costs, Not Quality: Exploring the Best Cheap CNC Material OptionsDecember 4, 2023In today's competitive market, every business is constantly finding ways to cut costs without compromising the quality of their products or services. When it comes to CNC machining, one of the mos...view Alloy Steel vs Carbon Steel: Which Is Better?September 5, 2023Steel is a major global industry that involves the combination of iron with other elements, both metallic and non-metallic, to create a versatile material. This combination is done to attain specific ...view

Alloy Steel vs Carbon Steel: Which Is Better?September 5, 2023Steel is a major global industry that involves the combination of iron with other elements, both metallic and non-metallic, to create a versatile material. This combination is done to attain specific ...view Unraveling the World of Machined Springs: Your Ultimate GuideNovember 9, 2023As a CNC machining service provider, we at Richconn understand the significance of precision engineering and how it's all about the details. In the realm of mechanical components, one topic that piques the curiosity of engineers, manufacturers, and professionals alike is -Machined Springs. In this comprehensive guide, I will walk you through the intricacies of Machined Springs, from the fundamentals to their applications, performance characteristics, manufacturing processes, and more.view

Unraveling the World of Machined Springs: Your Ultimate GuideNovember 9, 2023As a CNC machining service provider, we at Richconn understand the significance of precision engineering and how it's all about the details. In the realm of mechanical components, one topic that piques the curiosity of engineers, manufacturers, and professionals alike is -Machined Springs. In this comprehensive guide, I will walk you through the intricacies of Machined Springs, from the fundamentals to their applications, performance characteristics, manufacturing processes, and more.view