In the field of CNC numerical control machining, the correct selection of suitable materials is crucial to the performance, accuracy and durability of parts. Different environments and application scenarios require different types of materials, and the following will analyze how to choose the right material from several aspects.

Different working environments have different requirements for materials, such as high temperature, low temperature, humidity, corrosion and so on. In high-temperature environments, heat-resistant alloys such as Inconel or titanium alloys may be more suitable, while in corrosive environments, stainless steel or nickel-based alloys may be more advantageous.

Physical properties such as density, hardness, strength, and rigidity of the material will directly affect the performance of the part. For example, the need for high strength parts may choose to use high-strength steel materials, while the need for lightweight parts may consider the use of aluminum alloys.

The processing performance of the material will affect the manufacturing process and accuracy of the parts. Some materials may be easier to cut and process, while other materials may require more specific processing methods. Harder materials may require more wear-resistant tools.

In some applications that require heat dissipation or thermal conductivity, thermal conductivity becomes an important consideration. Copper and its alloys usually have good thermal conductivity and are suitable for parts with high thermal conductivity requirements.

The cost of the material is also an important consideration. High-performance specialty materials usually cost more, while some general-purpose materials are more economical. When balancing performance and cost, the choice needs to be made on a case-by-case basis.

Take a look at materials used in different environments:

High-temperature environments: titanium alloys, nickel-based alloys, heat-resistant steels, etc. for high-temperature operating conditions such as aerospace and gas turbines.

Corrosive environment: stainless steel, corrosion-resistant alloys, ceramics, etc., suitable for chemical, marine and other corrosive environments.

Low temperature environment: cryogenic steel, aluminum alloys, plastics, etc., suitable for liquefied natural gas, cryogenic experiments and other low-temperature scenarios.

Electronic field: copper, aluminum, thermoplastic, etc., applicable to the manufacture of electronic parts with high conductivity requirements.

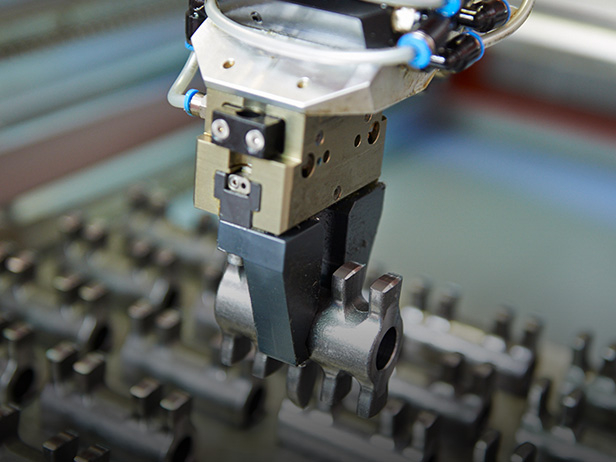

Structural parts: carbon steel, alloy steel, aluminum alloy, etc., suitable for general engineering applications such as mechanical structures and automotive parts.

Wear resistance: Cemented carbide, ceramic materials, engineering plastics, rubber, these wear-resistant materials are widely used in various fields such as mining, machinery manufacturing, automotive, aerospace, chemical, energy and so on.

In addition to the aforementioned factors, the material's fatigue resistance, electrical conductivity, magnetism, the possible presence of chemical agents in the environment, radiation and other factors also need to be taken into account, as well as the need to work closely with engineers, designers, and materials professionals.CNC machining parts of the material selection is a complex process, which needs to find the optimal balance between a number of factors. As technology continues to evolve, more innovative materials will emerge in the future, opening up more possibilities for a wide range of industries and requiring updated knowledge and practices to meet the challenges of changing material requirements.

In the field of CNC numerical control machining, the importance of material selection cannot be ignored. As technology continues to advance and industrial needs diversify, the properties and suitability of materials become more diverse. Depending on the specific application and requirements, choosing the right material can optimize the performance and reliability of the part.

Metal Plating Finishes: Picking the Best for Your Custom PartsMay 16, 2024What are metal plating finishes? How are they applied? What are their benefits and drawbacks? Find out in this guide to metal plating finishes.view

Metal Plating Finishes: Picking the Best for Your Custom PartsMay 16, 2024What are metal plating finishes? How are they applied? What are their benefits and drawbacks? Find out in this guide to metal plating finishes.view How to Measure Surface Roughness?August 2, 2023In order to ensure the optimal quality of parts, the surface of components after manufacturing applications must be maintained within the desired range of roughness. Surface treatment plays a critical...view

How to Measure Surface Roughness?August 2, 2023In order to ensure the optimal quality of parts, the surface of components after manufacturing applications must be maintained within the desired range of roughness. Surface treatment plays a critical...view CNC Machining: Insights into Mass and Small Batch ProductionsJuly 19, 2024Dive into the detailed exploration of CNC machining to empower your business decisions! Let’s discover the pros of mass and small batch production, shifts in the industry, and tips for choosing the best.view

CNC Machining: Insights into Mass and Small Batch ProductionsJuly 19, 2024Dive into the detailed exploration of CNC machining to empower your business decisions! Let’s discover the pros of mass and small batch production, shifts in the industry, and tips for choosing the best.view Welding vs. Riveting: Differences, Advantages and DisadvantagesNovember 28, 2023Metal joining is a process of attaching or combining two or more metal pieces or parts together. Metal joining is essential for various industries, such as construction, automotive, aerospace, and manufacturing.view

Welding vs. Riveting: Differences, Advantages and DisadvantagesNovember 28, 2023Metal joining is a process of attaching or combining two or more metal pieces or parts together. Metal joining is essential for various industries, such as construction, automotive, aerospace, and manufacturing.view What Tool is Best for Cutting Metal?October 8, 2023Cutting metal is a very common task in metalworking projects and different types of tools may be required for different metals and cutting requirements.view

What Tool is Best for Cutting Metal?October 8, 2023Cutting metal is a very common task in metalworking projects and different types of tools may be required for different metals and cutting requirements.view Climb vs Conventional Milling: What Are the Differences?March 20, 2024Understanding climb vs conventional milling clearly is one way to help you choose the right milling process. Here is a comprehensive guide to their differences.view

Climb vs Conventional Milling: What Are the Differences?March 20, 2024Understanding climb vs conventional milling clearly is one way to help you choose the right milling process. Here is a comprehensive guide to their differences.view

EN

EN

ru

ru