One of the ambitious goals of the manufacturing industry is to complete processing in one go: putting a piece of material into a machine tool, running a program, and finally obtaining a perfectly Machined part. It can be said that five-axis machining is more likely to approach the goal of "one-time completion" than any other process. Five-axis machining is the use of CNC to move parts or cutting tools simultaneously in five different axes. It can process very complex parts, which is why five-axis machining is particularly popular in the aerospace field.

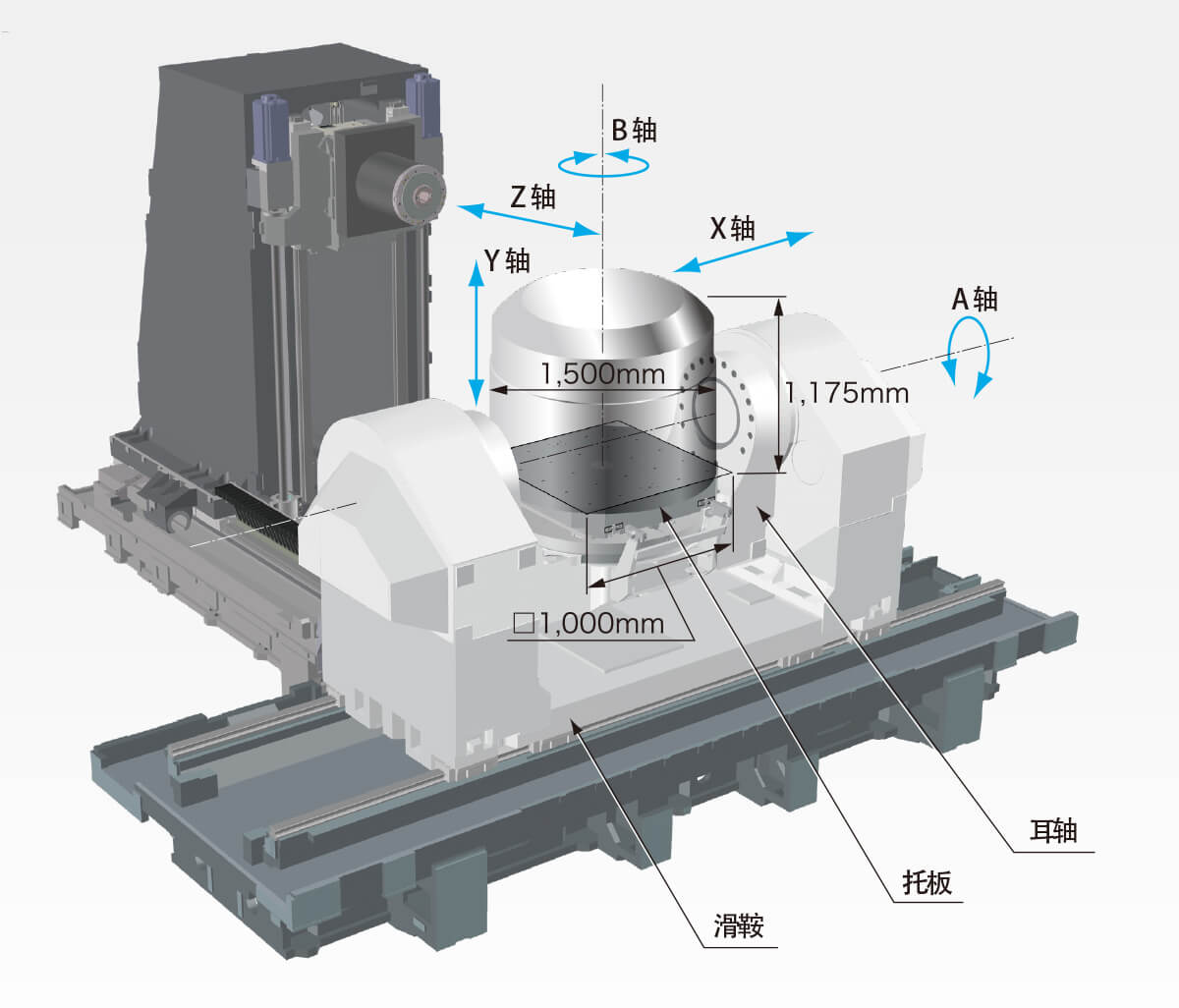

5-axis CNC machining is a technology for CNC machining of complex parts using a 5-axis control system on a CNC machine tool. 5-axis CNC machining includes X, Y, Z, A, and C axes, which can be moved simultaneously or partially to make the machine tool capable of moving in any direction, thus achieving the machining of complex parts.

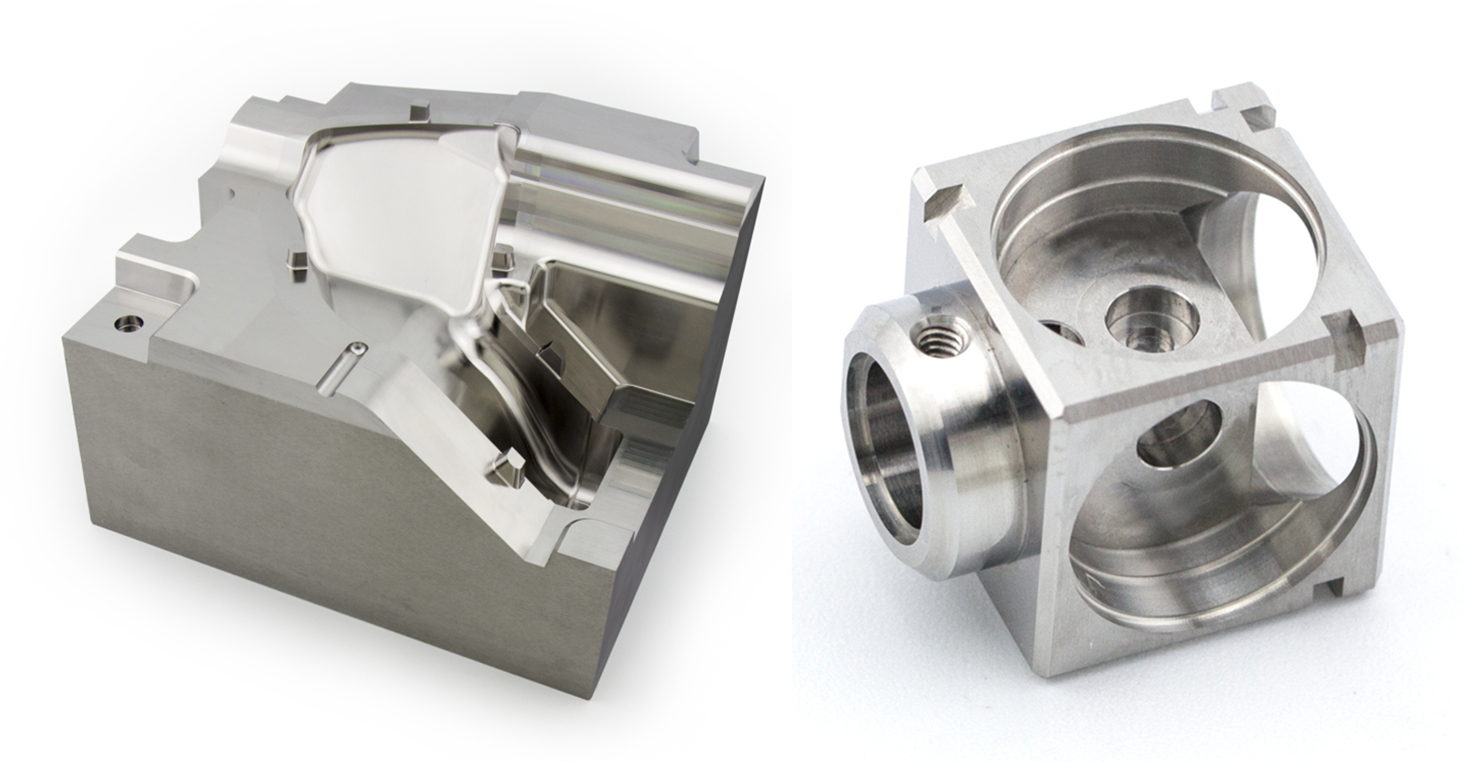

Five-axis is already a comprehensive processing ability that can achieve one-time clamping, reduce clamping costs, and reduce product scratches and collisions. Five-axis CNC machining is suitable for processing some multi-position holes and planes, high precision parts, especially parts with strict shape machining accuracy requirements. There are many benefits to using 5-axis CNC machining, as follows:

5-axis CNC machine tools make it possible to easily machine complex shapes in one setup. It does not require multiple setups, which can cause errors. Single setup helps reduce setup and manufacturing time and increase productivity. In addition to shortening delivery time, this machining technology also helps improve production and cash flow.

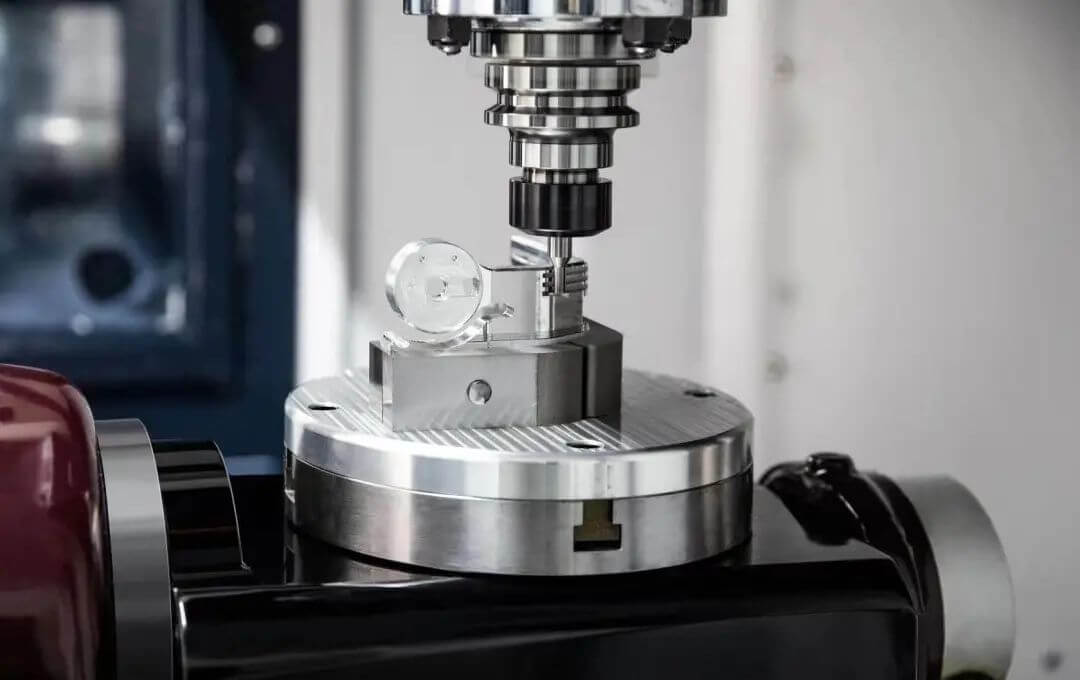

As 5-axis CNC machining allows movement along the X and Y axes simultaneously, you can use shorter and more rigid cutting tools. Using shorter and rigid cutting tools helps to speed up the cutting speed while minimizing or neglecting vibrations.

During the 5-axis CNC machining process, the workpiece is stationary and higher part accuracy can be achieved.

The use of shorter cutting tools in the 5-axis CNC machining process helps achieve excellent surface finish, thereby obtaining better part quality.

With this machining technology, you can manufacture extremely complex OEM CNC machining parts in a shorter time and at a lower cost. This is a great advantage for small-scale operations or prototypes.

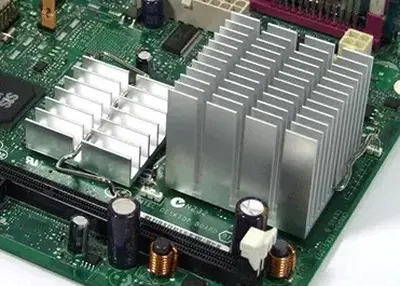

Heat Sinks: What They Are, How They Work, and How to Design ThemDecember 8, 2023Have you ever wondered how your laptop, smartphone, or gaming console can run so fast without overheating? The answer is heat sinks. Heat sinks are devices that help to cool down electronic components by transferring heat away from them. They are essential for ensuring the reliability and performance of many modern devices.view

Heat Sinks: What They Are, How They Work, and How to Design ThemDecember 8, 2023Have you ever wondered how your laptop, smartphone, or gaming console can run so fast without overheating? The answer is heat sinks. Heat sinks are devices that help to cool down electronic components by transferring heat away from them. They are essential for ensuring the reliability and performance of many modern devices.view How to Choose the Right CNC Machining Manufacturer?January 30, 2024Discover tips for selecting the CNC machining manufacturer. Learn about key criteria, including expertise, capabilities, lead times, warranty policies, etc.view

How to Choose the Right CNC Machining Manufacturer?January 30, 2024Discover tips for selecting the CNC machining manufacturer. Learn about key criteria, including expertise, capabilities, lead times, warranty policies, etc.view Ten Questions and Answers About Stainless Steel Valves: Unlocking the Secrets of Check ValvesAugust 11, 2023IntroductionIn this comprehensive article, we will delve deep into the mysteries of stainless steel valves, with a particular focus on the working principles and applications of check valves across di...view

Ten Questions and Answers About Stainless Steel Valves: Unlocking the Secrets of Check ValvesAugust 11, 2023IntroductionIn this comprehensive article, we will delve deep into the mysteries of stainless steel valves, with a particular focus on the working principles and applications of check valves across di...view Top 6 Types of Rivets and Their Common UsesAugust 11, 2023Rivets hold a unique position in the history of engineering and construction. These seemingly small fasteners have played a critical role in joining materials together. Based on their properties and d...view

Top 6 Types of Rivets and Their Common UsesAugust 11, 2023Rivets hold a unique position in the history of engineering and construction. These seemingly small fasteners have played a critical role in joining materials together. Based on their properties and d...view Brass vs Bronze vs Pure Copper vs Copper Alloys: An in-depth look at their differencesSeptember 26, 2023The comparison of brass to bronze to copper and its copper alloys is crucial as these metals can be easily confused. In addition, the distinction between these materials is also very subtle. As a result, development engineers or designers can be seriously confused when it comes to material selection. In particular, the similarity of these metal constituent elements makes it more difficult to classify and select them.view

Brass vs Bronze vs Pure Copper vs Copper Alloys: An in-depth look at their differencesSeptember 26, 2023The comparison of brass to bronze to copper and its copper alloys is crucial as these metals can be easily confused. In addition, the distinction between these materials is also very subtle. As a result, development engineers or designers can be seriously confused when it comes to material selection. In particular, the similarity of these metal constituent elements makes it more difficult to classify and select them.view CNC Machining Services and Engineered Machined Products: Meeting Manufacturing NeedsNovember 7, 2023Are you looking to understand the world of CNC machining and engineered machined products better? You're in the right place! I'm here to guide you through the intricate world of CNC machining, engineered machined products, and how Richconn can be your trusted partner in this journey.view

CNC Machining Services and Engineered Machined Products: Meeting Manufacturing NeedsNovember 7, 2023Are you looking to understand the world of CNC machining and engineered machined products better? You're in the right place! I'm here to guide you through the intricate world of CNC machining, engineered machined products, and how Richconn can be your trusted partner in this journey.view

EN

EN

ru

ru