Laser engraving, a seemingly simple yet profound field of science and technology, utilizes high-energy laser beams to make fine cuts, holes, and engravings in a variety of materials. This technology, with its unique advantages, has been widely used in various fields, such as industrial manufacturing, medical equipment, and artwork production. Before using the technology in your project, here is all the information you need to know.

The procedure entails vaporizing particular regions on practically any material using a laser marking device, which we will refer to as a laser engraving machine. As a result, it creates permanent markings on the part or product that contrast more than the unmarked areas.

Parts with logos, barcodes, serial numbers, and QR codes can be marked with this procedure. In conjunction with laser etching, annealing, ablation, and further laser marking technologies, this procedure creates a collection of extremely dependable procedures for product decorating, traceability, and identification.

One cannot discuss the history of engraving laser without first discussing manual engraving. The method of manual engraving entails putting a marking on the part with an engraving tool or other sharp instrument. For instance, about 500,000 years ago, stones were used as engraving tools. The earliest piece that has been painstakingly engraved to date is from roughly 500,000 years ago. The development of technology over time led to changes in manual engraving. The LASER concept developed by Albert Einstein in 1916 and its subsequent optimization in the 1950s would serve as the foundation for the laser engraving technique.

The first optical laser was invented by Theodore Maiman. The original laser light would be credited to Gordon Gould.

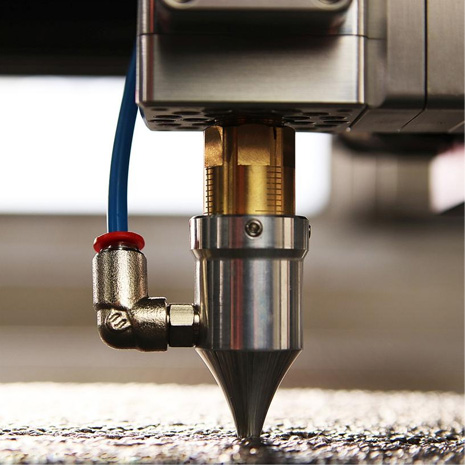

How does laser engraving work? The process of laser light engraving entails directing a laser beam at an appropriate power level and at a distance onto a part. This causes the substance to evaporate, permanently branding the components. It's crucial to adjust the wattage since too much will burn the material and too little will be ineffective.

The procedure of laser engraving is quite simple. The procedures to laser engrave a part are as follows:

Concept

Creating concepts for the markings' appearance and the best materials to use is known as ideation. It calls for a lot of inventiveness. Since it decides the effectiveness and quality of the markings, it is the most crucial stage in the deep laser engraving process. Because laser-engraved markings are permanent, ideation is also crucial. Consequently, after the marking procedure is complete, it is difficult to correct incorrect markings.

Create the Visual Image for Marking

On a computer application, create the image you wish to mark. Inkscape, Lightburn, DraftSight, Onshape, and Adobe Illustrators can all be used to produce graphic designs. It is also necessary to confirm if the machine can open the planned file.

Laser Engraving Materials

Select a material that goes well with your design and can be used with the laser engraver. Metals, polymers, glass, and stone are among the materials that laser engraving devices typically operate with. Every kind is appropriate for a distinct set of materials, though. For instance, CO2 laser markers work well with organic materials, whereas UV laser markers work well with plastics since they are cold lasers that don't generate a lot of heat.

Set up the Machine

The engraving process is divided into distinct steps by the types and settings of the machines. Adjust the laser power, depth of cut, speed, number of passes, and line thickness. Then, see the effects of these settings on comparable test materials. Save the ideal configurations that represent your preferences.

The Part Engraved by Laser

After inserting the material, mark it in the machine. The material can be taken out of the machine and cleaned before marking.

Numerous materials can be used with the laser engraving method. Here are several that you might want to think about for your project.

Plastics

Common materials for laser engraving include acrylic and POM. However, the laser's power needs to be properly controlled and adjusted to the material's absorption spectrum as well as any other additives that may be present. UV laser markers and CO2 are more suitable for plastics.

Metals

The phrase "the heart of many industries" refers to the fact that metals are the most often utilized material for laser engraving. Aluminum, gold, silver, iron, and stainless steel are among the metals that work well with the procedure. The best marking tools for metals are fiber optic engraving machines. The accuracy of laser metal engraving is remarkable. The laser acts directly on the metal surface, allowing for micron-level precise cutting and engraving due to its high energy density. As a result, there are several potential applications for metal laser engraving in the manufacturing, aviation, and medical industries, among other sectors. Second, productivity is significantly increased by the metal engraving laser's speed and efficiency. Besides, there are some other ideas for laser engraving. For example, artists also like applying laser engraving on metal like metal foils and wires to create unique handcrafts.

Coated Metals

Because it can be used to evaporate the metal's coating, the procedure is also appropriate for coated metals. This causes the coating to be removed cleanly.

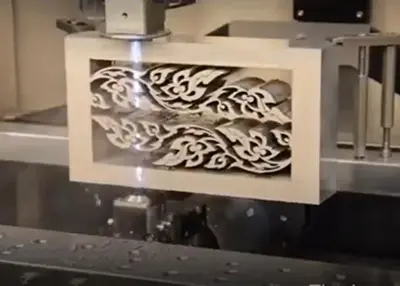

The woods

Woods work well with the procedure as well. Their high heat content makes them a fire threat to many. It is possible to adjust the laser marker's power so that wood can be engraved without catching fire. A common wood substance that can be machine-engraved is plywood, along with MDF and cardboard.

Due to its benefits, including its ability to work with a variety of materials, accuracy, and quick production speeds, laser engraving is well-known in the business. Nevertheless, there are drawbacks to the procedure as well. Here are some benefits and drawbacks you should be aware of.

1. High precision

Laser engraving is widely utilized in various industries, including medical, electronic, and micromechanical, because of its extremely high precision, which can reach the nano level.

2. Quick speed

Laser engraving is incredibly quick and can engrave a lot of data in a short amount of time, which significantly increases manufacturing productivity.

3. Suitable for a range of materials

There are many uses for laser engraving, and it can be done on a number of materials, such as paper, plastic, wood, metal, and more. So, customers now have more options when it comes to materials and style.

4. Non-polluting and environmentally friendly

Laser engraving is an environmentally friendly manufacturing technology that doesn't release any dangerous compounds into the environment.

5. Marking without contact

Since it is a non-contact marking method, the part's mechanical and physical characteristics are not distorted or contaminated. This is not the same as inkjet marking, where the materials might not be compatible with the chemicals, or dot peening when the materials are struck by the stylus.

6. Reliability

Because they are repeatable, laser markers work well for batch marking. The design is stored by the machine's software, which allows it to mark and accrete similar markings on various or identical elements. Repeatability guarantees both aesthetically beautiful items and a quicker turnaround time.

7. Durability of marks

Permanent and with a strong contrast, laser engraved marks are easier to see. As a result, they hold up well against various environmental factors like heat, chemicals, and abrasion. This contrasts with other marking methods, including inkjet marking, where the marking agent may wash off in unfavorable conditions. Laser-etched markings are appropriate for product identification and traceability due to their durability.

1. Expensive

If you want to know how much does laser engraving cost? The answer is that laser engraving cost high because its equipment is rather costly and necessitates a financial commitment.

2. High maintenance costs

The laser requires frequent upkeep and part replacement, which raises the cost of maintenance.

3. High environmental requirements

In order to avoid affecting the laser's performance, dust, moisture, and other impurities must be removed from the area where laser engraving is being done.

Professional laser engraving services are offered by Richconn for permanent marking on machined items. Because our staff are proficient in laser marking technologies, we can ensure quick turnaround times for engraved products of excellent quality. We provide the quickest lead time at a price that is competitive. Upon uploading your CAD file to our online quotation platform, you will receive an automated DfM report and quick quotes. Here are a few advantages of Richconn:

Technical strength

Richconn has a professional technical team, who have rich experience in solving laser engraving problems and solutions. It is able to skillfully use all kinds of laser equipment and technologies to provide customers with high-quality products.

Service level

We promise to provide our customers with fast and efficient service, and we will try our best to solve whatever problems you encounter. We value every customer's feedback and actively improve our service quality.

Quality assurance

We adopt strict quality control measures to ensure that each product meets customers' requirements. Our products are stable, reliable, durable, and widely praised by our customers.

Reasonable price

we offer competitive prices so that your costs are greatly reduced. We are committed to providing our customers with affordable products and services of the best quality.

Customized services

Richconn can provide customized laser engraving services according to customers' needs. We are able to design unique and beautiful patterns and text according to your requirements to meet your personalized needs.

There is confusion between laser marking, laser etching and laser engraving. It is crucial to understand how the three processes differ from one another. The differences between the three processes are listed below:

In laser etching, the material is melted and raised on the surface using a laser-powered device. In contrast to laser engraving, because of the high energy needed, it can only be done using a fiber laser marker. Additionally, whereas laser etching removes a tiny portion (first thousandth of an inch) from the items' surface, laser engraving removes a larger portion of the material to make the noticeable marking.

Laser marking is the process of applying high-contrast markings to various parts utilizing machinery driven by lasers. It consists of multiple steps, including as annealing, ablation, engraving, and laser etching.

Laser engraving is a non-contact method that yields fine, long-lasting, and accurate marks. For this reason, it is a crucial procedure for product traceability and identification in a number of businesses.

Do you require excellent laser engraving and branding services? How about we assist you in getting started?

Titanium vs Steel: Is Titanium Stronger Than Steel?August 29, 2023Is titanium stronger than steel? Here's a brief guide that compares steel to titanium from different aspects.view

Titanium vs Steel: Is Titanium Stronger Than Steel?August 29, 2023Is titanium stronger than steel? Here's a brief guide that compares steel to titanium from different aspects.view A Comprehensive Guide to Choosing CNC Machining ToolsJuly 19, 2023Description:Discover how to select suitable CNC machining tools through this comprehensive guide. Explore key considerations for choosing CNC machining tools, different tool types, and expert advice t...view

A Comprehensive Guide to Choosing CNC Machining ToolsJuly 19, 2023Description:Discover how to select suitable CNC machining tools through this comprehensive guide. Explore key considerations for choosing CNC machining tools, different tool types, and expert advice t...view How to Choose CNC Machining Service Provider?October 25, 2023This article covers everything you need to know about quality control in your CNC machine shop. It will serve as a guide to help you quickly identify machine shops that you should work with and must avoid.view

How to Choose CNC Machining Service Provider?October 25, 2023This article covers everything you need to know about quality control in your CNC machine shop. It will serve as a guide to help you quickly identify machine shops that you should work with and must avoid.view CNC Powder Coating in Healthcare Equipment ApplicationsFebruary 29, 2024In the world of healthcare equipment, precision and durability are of the utmost importance. From monitoring devices to surgical tools, every piece of equipment must be able to withstand the demanding...view

CNC Powder Coating in Healthcare Equipment ApplicationsFebruary 29, 2024In the world of healthcare equipment, precision and durability are of the utmost importance. From monitoring devices to surgical tools, every piece of equipment must be able to withstand the demanding...view CNC Turning Process And Process AnalysisJune 21, 20221. The content of CNC turning processThe CNC turning process is the sum of the methods and technical means used when CNC lathes are used to process parts. Its main contents include the following aspec...view

CNC Turning Process And Process AnalysisJune 21, 20221. The content of CNC turning processThe CNC turning process is the sum of the methods and technical means used when CNC lathes are used to process parts. Its main contents include the following aspec...view Unveiling the World of Complex Machined Parts: A Comprehensive ExplorationNovember 14, 2023Embark on a journey into the intricate realm of complex machined parts, where precision meets innovation and engineering excellence takes center stage. In this comprehensive exploration, we'll delve into the definition, manufacturing processes, applications across industries, quality standards, material selection, market trends, and even the key players in the supply chain. Get ready to unlock the secrets behind these components that power the machinery shaping our modern world.view

Unveiling the World of Complex Machined Parts: A Comprehensive ExplorationNovember 14, 2023Embark on a journey into the intricate realm of complex machined parts, where precision meets innovation and engineering excellence takes center stage. In this comprehensive exploration, we'll delve into the definition, manufacturing processes, applications across industries, quality standards, material selection, market trends, and even the key players in the supply chain. Get ready to unlock the secrets behind these components that power the machinery shaping our modern world.view