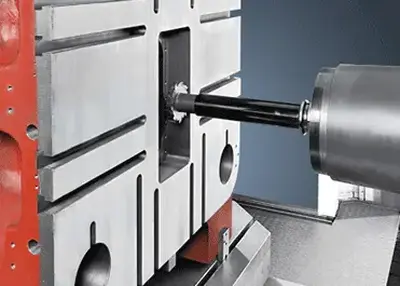

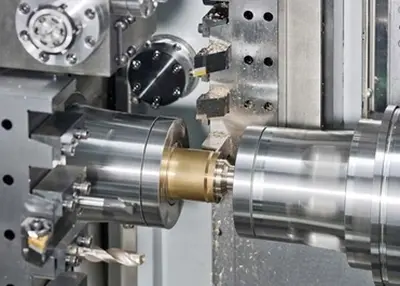

CNC machining technology mainly includes CNC machine tool machining technology and CNC machine tool programming technology. CNC machine tool machining technology directly completes the surface processing of parts and plays a decisive role in product quality. (Add CNC machine tool image) CNC programming technology converts part sizes into digital code instructions to guide CNC machine tool machining, which is also a key technology.

CNC programming converts part design drawings into numeric code programs that can be recognized by CNC machine tools. The codes in the program follow specific rules and formats. (Add program code example image) The key to programming is to convert part process requirements into machine tool operation instructions through code parameters. Proficient CNC programming requires an in-depth understanding of programming specifications and CNC machine tool performance.

The main steps of OEM CNC machining include: programming → program verification → program transfer to CNC system → CNC system reads program → CNC system calculates and issues instructions → CNC machine tool executes machining → product inspection.

1. Programming: Convert part design drawings into numeric code programs that can be recognized by CNC machine tools.

2. Program verification: Confirm that the program is correct and meets the design requirements.

3. Program transfer to CNC system: (Add CNC system schematic diagram) Import the verified program into the CNC system memory.

4. CNC system reads program and calculates: The CNC system reads the program code from memory, parses and calculates various parameters required for machine tool operation.

5. CNC system issues instructions: The CNC system issues motion control instructions to drive the CNC machine tool to operate. (Add production machining photos)

6. CNC machine tool machining: Complete surface machining of parts according to instructions to meet design requirements.

7. Product inspection: Inspect whether the machined part indicators meet the design requirements.

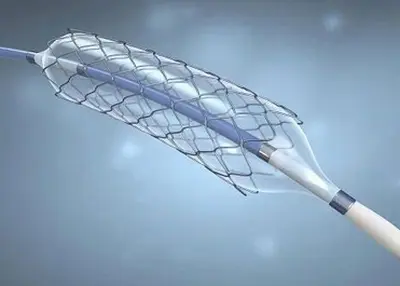

Custom Machined Metal Parts: Precision at Your FingertipsNovember 9, 2023Do you crave perfection in your machinery? Are you seeking the ideal metal components for your projects? You've come to the right place! Welcome to Richconn, your reliable partner for custom machined metal parts. In this comprehensive guide, we'll explore the world of precision engineering, from understanding the basics to choosing the right materials, processes, and designs.view

Custom Machined Metal Parts: Precision at Your FingertipsNovember 9, 2023Do you crave perfection in your machinery? Are you seeking the ideal metal components for your projects? You've come to the right place! Welcome to Richconn, your reliable partner for custom machined metal parts. In this comprehensive guide, we'll explore the world of precision engineering, from understanding the basics to choosing the right materials, processes, and designs.view What Are the High Temperature and Corrosion Resistant High Hardness Alloy Wear Resistant Metal Materials?October 30, 2023Corrosion-resistant metals are used in a wide range of applications, from the culinary industry to aerospace applications. Like most metals, they provide structural strength and heat resistance, but the metals listed in this article are also more resistant to corrosion than others.view

What Are the High Temperature and Corrosion Resistant High Hardness Alloy Wear Resistant Metal Materials?October 30, 2023Corrosion-resistant metals are used in a wide range of applications, from the culinary industry to aerospace applications. Like most metals, they provide structural strength and heat resistance, but the metals listed in this article are also more resistant to corrosion than others.view Navigating the World of Horizontal Boring TechnologyNovember 23, 2023Horizontal boring technology encompasses a realm of precision and innovation within precision CNC machining. At its core, it involves the utilization of specialized machinery, notably horizontal boring machines and mills, to create intricate cavities, bores, and holes with utmost accuracy.view

Navigating the World of Horizontal Boring TechnologyNovember 23, 2023Horizontal boring technology encompasses a realm of precision and innovation within precision CNC machining. At its core, it involves the utilization of specialized machinery, notably horizontal boring machines and mills, to create intricate cavities, bores, and holes with utmost accuracy.view What Is 3-axis, 4-axis, and 5-axis CNC Machining?April 4, 2023CNC machining has become one of the most critical manufacturing processes used in workshops globally. By adding computer control to previous manual processes, the accuracy and precision of machining p...view

What Is 3-axis, 4-axis, and 5-axis CNC Machining?April 4, 2023CNC machining has become one of the most critical manufacturing processes used in workshops globally. By adding computer control to previous manual processes, the accuracy and precision of machining p...view Ultra-High Precision Laser Cutting Technology: A Detailed Explanation of Its Technology and ApplicationsJanuary 3, 2024We delve into the intricacies of ultra-high-precision laser cutting, exploring its technology, applications, benefits and challenges.view

Ultra-High Precision Laser Cutting Technology: A Detailed Explanation of Its Technology and ApplicationsJanuary 3, 2024We delve into the intricacies of ultra-high-precision laser cutting, exploring its technology, applications, benefits and challenges.view Inconel 718: A Superalloy with Lasting RelevanceOctober 12, 2023Metal 3D printing has finally catapulted Inconel, the classic nickel-based heat-resistant alloy, into the 21st century. Inconel 718, the hardened version of Inconel 625, is the latest addition to our growing range of metals for Direct Metal Laser Sintering (DMLS).view

Inconel 718: A Superalloy with Lasting RelevanceOctober 12, 2023Metal 3D printing has finally catapulted Inconel, the classic nickel-based heat-resistant alloy, into the 21st century. Inconel 718, the hardened version of Inconel 625, is the latest addition to our growing range of metals for Direct Metal Laser Sintering (DMLS).view

EN

EN

ru

ru