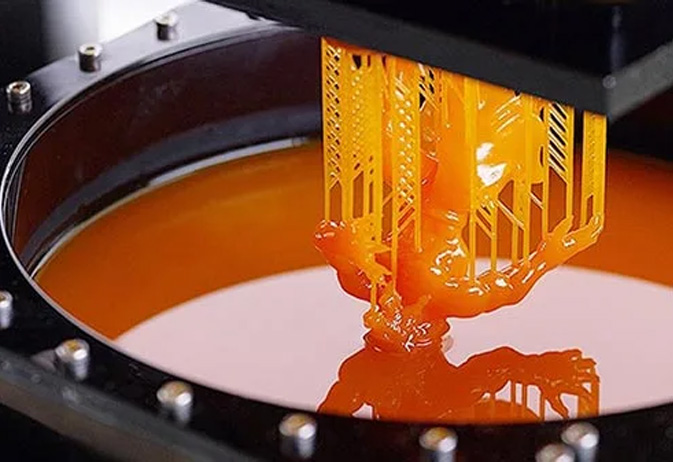

The automotive sector has been an early and major adopter of 3D printing technology. Initially used primarily for prototyping, 3D printing has now advanced to the point where some modern cars are being produced with fully 3d printing car parts. Following the lead of major automotive companies, smaller businesses have also started to incorporate 3D printing technology. As the cost of equipment has decreased, 3D printing has become more accessible for experimentation. This has led to smaller ventures, such as custom body shops and smaller racing teams, utilizing 3D printing to manufacture various parts, including ducts, caps, vents, and even mechanical components. In this article, let’s take a closer look at the 3d print car parts.

You can use 3D printing for the production of most car spare parts. One of the most exciting uses of 3D printing is in the automotive industry, where it is utilized for producing prototype, functional, and customized car parts. This technology enables the efficient and cost-effective manufacturing of intricate dashboard components, entire body panels, and more, catering to a wide range of users.

Traditionally, 3D printing has been mainly used for creating jigs and fixtures for car production, such as alignment tools and symmetry checkers. However, there is a growing trend among manufacturers to incorporate fully functional 3D printing automotive parts into their vehicles. Additionally, hobbyists, enthusiasts, and small service providers can leverage this technology to customize vehicles and produce 3d printed car accessories.

Although fully 3d printing cars have not been realized yet, the impact of 3D printing on the automotive manufacturing sector is undeniable. Let's see why 3D printing is becoming increasingly popular in the fabrication of automotive components.

Cost-efficient

3D printing offers a cost-effective solution by significantly decreasing production costs through the reduction of waste. Additionally, it helps to lower inventory expenses by enabling the on-demand printing of parts as needed.

Rapid Prototyping

Creating prototypes is crucial in the automotive manufacturing process, but it can be costly and time-consuming to use real car components for this purpose. Furthermore, as prototypes often need multiple iterations, the traditional approach can be slow. This is where 3D printing of car parts proves valuable. In contrast to conventional methods, 3D printing accelerates and reduces the cost of prototyping. Rapid prototyping with 3d printer for car parts offers enhanced flexibility, allowing for the production of a prototype as quickly as one day.

Improved Properties

The increased flexibility in design afforded by 3D printing technology allows for the creation of highly efficient structures in car parts, leading to weight savings and enhanced airflow. By utilizing a combination of different materials tailored to provide specific characteristics, 3D printing enables the production of high-quality automotive components that deliver superior performance benefits.

If you want to try DIY 3D printing, you must know the various materials that can work for the procedure. While various materials can work, we’ll only review three types that can work with almost all types of 3d PRINTERS. These three include:

1. ABS

ABS is the preferred material for 3D printing automotive components due to several key advantages. Firstly, it has a wide temperature tolerance of -20°C to 80°C, making it suitable for long-term use. Additionally, ABS is known for its flexibility and ability to withstand shocks. Lastly, its high transition-to-glass temperature sets it apart from other materials, enabling it to endure higher temperatures during operation. However, it is prone to warping; hence, using a 3D printer with a heated bed is advisable when working on ABS.

2. PLA

If you find ABS warping to be a problem, PLA filament is a better alternative for 3D printing car parts. PLA is ideal for printers without heated enclosures and is less prone to warping. However, it is not as impact-resistant as ABS and has a lower transition-to-glass temperature.

3. PETG

PETG can be considered as an advancement over PLA in the world of 3D printing. This filament is compatible with 3D printers that lack heated printer beds and generally exhibit better adhesion properties than PLA. Additionally, PETG boasts enhanced shock and heat resistance compared to its counterpart. Despite these advantages, PETG is typically priced similarly to PLA. The primary drawback associated with PETG filament is its intermittent tendency to exhibit subpar adhesion during printing processes.

Cars are made up of various components, with some not being manufactured by the car company itself. Understandably, certain parts may not be produced by these companies due to lower demand, which could result in delayed production cycles if they choose to produce them. Alternatively, you have the option to create the needed parts that are not readily available by engaging in a small-scale 3D service. Another possibility is to act as a distributor for these parts by outsourcing low-volume production to companies such as Richconn.

Provide car body parts that are tailored to your customer’s specific vehicle, desire, and needs. No more relying on off-the-shelf parts, with Richconn 3D printing services. The cutting-edge 3D printing technologies can be used for producing functional prototypes, design demonstrations, customized parts, and more.

With all the advantages of 3D printing in the automotive industry, its rapidly increasing popularity is understandable. If you want to take the best 3d printing car parts, contact Richconn today to know more about their 3D printing and how they can benefit your business.

Electrophoresis Metal Coating in Laboratory AutomationFebruary 29, 2024Navigating Precision in Laboratory AutomationIn the dynamic landscape of scientific research, the central axis of efficiency revolves around laboratory automation. At the nucleus of this efficiency li...view

Electrophoresis Metal Coating in Laboratory AutomationFebruary 29, 2024Navigating Precision in Laboratory AutomationIn the dynamic landscape of scientific research, the central axis of efficiency revolves around laboratory automation. At the nucleus of this efficiency li...view Understanding Steel Material for Custom Prototyping: Properties, Grades, and ApplicationsMarch 14, 2024Let’s explore the diverse properties, grades and uses of steel material in prototyping, from its melting point to its versatility across different industry sectors.view

Understanding Steel Material for Custom Prototyping: Properties, Grades, and ApplicationsMarch 14, 2024Let’s explore the diverse properties, grades and uses of steel material in prototyping, from its melting point to its versatility across different industry sectors.view Unlocking the Brilliance of Machined Face WheelsNovember 8, 2023Are you ready to elevate your vehicle's style and performance to a whole new level? Look no further! In this comprehensive guide, I'll take you on an exciting journey to explore the world of machined face wheels. From understanding what they are to discovering their stunning aesthetics, identifying suitable vehicle models, and even delving into the intricacies of installation and maintenance, we've got it all covered.view

Unlocking the Brilliance of Machined Face WheelsNovember 8, 2023Are you ready to elevate your vehicle's style and performance to a whole new level? Look no further! In this comprehensive guide, I'll take you on an exciting journey to explore the world of machined face wheels. From understanding what they are to discovering their stunning aesthetics, identifying suitable vehicle models, and even delving into the intricacies of installation and maintenance, we've got it all covered.view Different Types of Bearings: Their Distinctive Features and Diverse UsesMay 28, 2024Learn about the importance of mechanical bearings, different types, and how to choose the right one for your needs. Explore applications in various fields and factors to consider for smooth and precise motions.view

Different Types of Bearings: Their Distinctive Features and Diverse UsesMay 28, 2024Learn about the importance of mechanical bearings, different types, and how to choose the right one for your needs. Explore applications in various fields and factors to consider for smooth and precise motions.view Is NTPT Carbon Fiber A Gimmick or A Manifestation of Value?May 30, 2022When it comes to carbon fiber watches, we have to mention Audemars Piguet. Audemars Piguet is definitely the ancestor of carbon used in watches. In those days, bumblebees were hard to find. This is al...view

Is NTPT Carbon Fiber A Gimmick or A Manifestation of Value?May 30, 2022When it comes to carbon fiber watches, we have to mention Audemars Piguet. Audemars Piguet is definitely the ancestor of carbon used in watches. In those days, bumblebees were hard to find. This is al...view Machining Commonly Used 24 Kinds of MaterialsOctober 23, 2023Can be used for CNC machining, mold processing of more than a hundred kinds of materials, metal, plastic, but according to the actual needs of different, each material use as well as the demand varies, the most commonly used 24 kinds of materials.view

Machining Commonly Used 24 Kinds of MaterialsOctober 23, 2023Can be used for CNC machining, mold processing of more than a hundred kinds of materials, metal, plastic, but according to the actual needs of different, each material use as well as the demand varies, the most commonly used 24 kinds of materials.view

EN

EN

ru

ru