Are you ready to delve into the intricate world of CNC machining and its remarkable connection with machined wheels? As an automotive enthusiast and CNC machining professional, I'm thrilled to guide you through this comprehensive exploration of the dynamic interplay between precision engineering and high-performance wheels. Let's roll!

CNC machining, short for Computer Numerical Control machining, is the heartbeat of modern manufacturing. With CNC technology, intricate designs and precise cuts are achieved effortlessly. From aerospace components to automotive parts, CNC machining is the foundation of quality engineering. Ready to explore the CNC universe? Let's dive in!

CNC machining is the process of using computer-controlled machines to create complex and precise parts and components. It is a cornerstone of modern manufacturing, playing a vital role in a wide range of industries. Let's take a closer look at what CNC machining entails:

| Aspect | Description |

|---|---|

| Definition | CNC machining involves using computer programs to control machinery and tools to produce intricate parts and components. It is highly automated and precise. |

| Key Processes | CNC machining encompasses processes such as milling, turning, drilling, and grinding. These processes are used to shape and cut materials like metal, plastic, and wood. |

| Precision | CNC machining is renowned for its exceptional precision. It can achieve tolerances within micrometers, making it ideal for applications that demand high accuracy. |

| Materials | CNC machines can work with a wide variety of materials, including metals, plastics, composites, and more. This versatility makes CNC machining suitable for various industries. |

| Applications | CNC machining is employed in industries such as aerospace, automotive, electronics, and healthcare. It is used to create components for engines, aircraft, medical devices, and more. |

Ready to explore the world of CNC machining? Now that we've laid the foundation, let's delve deeper into its applications and significance.

CNC machining finds extensive applications across various industries, each benefiting from its precision and versatility:

Aerospace Industry: In aerospace, precision is non-negotiable. CNC machining is used to create critical components such as turbine blades, aircraft frames, and landing gear.

Automotive Industry: In the automotive sector, CNC machining produces engine parts, transmission components, and machined wheels, enhancing both performance and aesthetics.

Electronics Industry: The production of electronic devices relies on CNC machining to create intricate parts like circuit boards, connectors, and casings.

Medical Industry: In healthcare, CNC machining is crucial for manufacturing medical implants, surgical instruments, and diagnostic equipment.

General Manufacturing: Beyond specific industries, CNC machining is used for general manufacturing, creating a vast array of components and products.

By achieving high precision and repeatability, CNC machining ensures the quality and reliability of these critical components. Whether you're driving a car, flying in an airplane, or using electronic gadgets, CNC machining plays a role in your daily life.

Machined wheels, the unsung heroes of automotive aesthetics and performance, are our focus here. These precision-crafted wheels are known for their stunning appearance and robustness. Ready to unveil the world of machined wheels? Let's explore the essentials!

Machined wheels, often referred to as "machine-finished wheels," are renowned for their striking appearance. They are known for their sleek and modern design, which adds a touch of elegance to any vehicle. These wheels are produced with precision machining techniques that create intricate patterns and designs on the wheel's surface. Here's what you need to know about their aesthetic appeal:

| Aspect | Description |

|---|---|

| Design Patterns | Machined wheels feature patterns and designs that are often created using CNC machining. These patterns can include intricate spokes, geometric shapes, and other unique motifs. |

| Finishes | Machined wheels are characterized by a shiny, metallic finish. This finish not only enhances the visual appeal but also complements the overall aesthetics of a vehicle. |

| Customization | Many car enthusiasts appreciate the ability to customize machined wheels. This customization can include different patterns, finishes, and color options. |

The aesthetic appeal of machined wheels is one of the key factors that make them highly desirable among car owners. They add a touch of sophistication and individuality to any vehicle.

In addition to their visual appeal, machined wheels are also known for their strength and durability. These wheels are designed to withstand the rigors of the road and provide a safe and reliable driving experience. Here are some aspects of their strength and durability:

| Aspect | Description |

|---|---|

| Material | Machined wheels are typically made from high-quality materials such as aluminum or alloy. These materials are chosen for their lightweight properties and resilience. |

| Weight | The lightweight nature of machined wheels helps reduce unsprung weight, which can improve a vehicle's handling and performance. |

| Strength | Despite their lightweight construction, machined wheels are engineered to be strong and capable of withstanding the demands of various driving conditions. |

The combination of aesthetic appeal, lightweight construction, and durability makes machined wheels a popular choice for car enthusiasts who value both style and performance.

CNC machining plays a pivotal role in the production of machined wheels. It is the precision machining process that allows for the creation of intricate designs and patterns on the wheel's surface. CNC machines can precisely etch and shape the wheel, resulting in the signature aesthetics of machined wheels. The synergy between CNC machining and machined wheels is what makes them stand out.

By using CNC machining, wheel manufacturers can achieve unmatched precision and consistency in the production of machined wheels. This not only ensures their stunning appearance but also contributes to their structural integrity. Whether you're a car enthusiast looking for an upgrade or a manufacturer seeking to produce high-quality machined wheels, the CNC machining process is the key to achieving these goals.

Understanding the essential characteristics of CNC machining and machined wheels is crucial for any automobile enthusiast. From material selection to performance attributes, this section reveals the heart of the matter. Curious about what makes CNC machining and machined wheels stand out? Let's dig deeper!

Materials are the building blocks of precision engineering, and CNC machining relies on the careful selection of materials to achieve its goals. When it comes to machining wheels, the choice of materials significantly influences their performance and aesthetics:

| Aspect | Description |

|---|---|

| Aluminum Alloy | Aluminum alloy is a popular choice for machined wheels due to its lightweight properties and excellent strength. It offers advantages in terms of reduced unsprung weight, which can improve vehicle handling. |

| Steel | Steel wheels are known for their exceptional durability and are commonly used for heavy-duty applications. They provide robust performance and can withstand challenging conditions. |

| Customization | CNC machining allows for precise material shaping, making it possible to create intricate designs on both aluminum alloy and steel wheels. This customization contributes to the unique appearance of machined wheels. |

The choice of material is a critical decision when designing machined wheels. Different materials cater to varying needs and preferences, making CNC machining a versatile process.

CNC machining is synonymous with precision and accuracy. The advanced technology behind CNC machines ensures that the desired dimensions and tolerances are consistently met. Here's what you need to know about CNC machining's precision:

| Aspect | Description |

|---|---|

| Tolerances | CNC machining can achieve extremely tight tolerances, often within micrometers. This level of precision is essential for producing high-quality components. |

| Complex Geometries | CNC machines can create complex shapes, contours, and features with great accuracy. This capability is valuable for crafting the intricate designs found on machined wheels. |

| Consistency | CNC machining offers exceptional consistency, ensuring that every machined wheel produced meets the same exacting standards. |

The precision offered by CNC machining is what makes it a preferred choice for crafting machined wheels. It ensures that each wheel is not only visually stunning but also structurally sound.

Machined wheels are more than just a pretty face. They bring notable performance enhancements to a vehicle. Here's what you need to know about their performance attributes:

| Aspect | Description |

|---|---|

| Reduced Unsprung Weight | Machined wheels, especially those made from lightweight materials, reduce unsprung weight. This contributes to improved handling, steering responsiveness, and overall vehicle performance. |

| Heat Dissipation | The design of machined wheels often includes features that enhance heat dissipation. This is crucial for brake cooling and maintaining consistent braking performance, especially in high-performance vehicles. |

| Structural Integrity | The combination of precision machining and high-quality materials ensures the structural integrity of machined wheels. They are built to withstand the stresses of everyday driving and offer longevity. |

Machined wheels not only enhance the aesthetics of a vehicle but also contribute to its performance capabilities. They are a testament to the seamless integration of form and function in the automotive world.

Machined wheels aren't one-size-fits-all; their compatibility varies across vehicle types and brands. Whether you're driving a sleek sports car or a rugged SUV, we'll help you navigate the ideal match. Ready to find the perfect set of wheels for your ride? Let's explore your options!

Sports cars demand a unique blend of style and performance, and machined wheels are often the perfect choice. These wheels offer benefits that align with the needs of sports car enthusiasts:

Lightweight Construction: Machined wheels made from aluminum alloy are exceptionally lightweight, reducing unsprung weight and enhancing agility.

Aesthetic Appeal: The intricate patterns and shiny finish of machined wheels complement the sleek design of sports cars.

Heat Dissipation: Performance driving generates heat, and machined wheels are designed to dissipate heat effectively, contributing to brake performance.

Whether you own a classic sports car or a modern high-performance model, machined wheels can elevate both aesthetics and handling.

SUVs and trucks are often associated with ruggedness and durability. Machined wheels designed for these vehicles cater to the demands of off-road adventures and heavy-duty usage:

Steel Wheels: Steel machined wheels are a popular choice for trucks and SUVs, known for their resilience and ability to withstand rough terrains.

Tough Design: Machined wheels for these vehicles often feature robust and practical designs that suit their utilitarian nature.

Durability: Built to withstand heavy loads and challenging conditions, machined wheels for SUVs and trucks are designed for longevity.

If you're an outdoor enthusiast or require a dependable set of wheels for your workhorse, machined wheels for SUVs and trucks are a fitting choice.

One of the remarkable aspects of machined wheels is the opportunity for customization. Many manufacturers and suppliers offer a range of options for personalization, allowing you to tailor your wheels to your preferences. Here are some ways you can customize your machined wheels:

Pattern Design: Choose from a variety of patterns and designs, from elegant to intricate, to match your vehicle's aesthetics.

Finish: Select the finish that best complements your vehicle, whether it's a glossy metallic sheen or a matte appearance. Some manufacturers, such as Richconn, even offer advanced metal finishing services to achieve the perfect finish.

Color Options: Some machined wheels can be painted or colored to match your vehicle's color scheme.

Customization gives you the freedom to express your individual style and make your vehicle truly unique. It's an opportunity to turn your vehicle into a reflection of your personality.

Now, let's unravel the magic behind the creation of machined wheels. From raw materials to CNC programming, discover the meticulous process that brings these wheels to life. Ready to peer into the CNC machining world? Let's see how it's done!

The journey of creating machined wheels starts with material selection. Manufacturers carefully choose the right material to match the wheel's intended use and performance requirements. Two common materials used for machined wheels are aluminum alloy and steel:

Aluminum Alloy: Aluminum alloy is a popular choice for machined wheels due to its lightweight properties and strength. It reduces unsprung weight, which can lead to improved vehicle handling. Aluminum alloy wheels are also highly customizable.

Steel: Steel wheels are known for their durability and are often chosen for heavy-duty applications. They are resilient and can withstand challenging conditions.

The material selected plays a crucial role in determining the wheel's characteristics, from weight to strength and overall performance.

The heart of producing machined wheels lies in the CNC machining process. CNC machines are employed to carve out intricate designs and patterns on the wheel's surface, giving them their unique appearance. The process involves several key steps:

Design and Programming: First, the design of the wheel, including the specific pattern or design, is created using computer-aided design (CAD) software. The CAD file is then used to program the CNC machine.

Raw Material Preparation: The selected material (aluminum alloy or steel) is prepared and loaded onto the CNC machine. It's essential to ensure precise alignment.

CNC Machining: The CNC machine, guided by the programmed instructions, begins to carve the design onto the wheel. The process involves milling, drilling, and precise cutting to create the desired pattern.

Quality Control: As the machining progresses, quality control measures are in place to ensure the design's accuracy and adherence to tight tolerances.

Finishing: After the machining process is complete, the wheels undergo a finishing process. This includes polishing, coating, and surface treatment to achieve the desired finish, whether it's a glossy metallic sheen or a matte appearance. Richconn, a trusted name in CNC machining, offers specialized metal polishing service and powder coating services to enhance the wheel's finish.

Inspection: Each wheel is carefully inspected for imperfections and deviations from design specifications. This step ensures that the final product meets the highest standards.

The precision and accuracy achieved through CNC machining, combined with Richconn's expertise in metal polishing and powder coating services, are what give machined wheels their stunning appearance and structural integrity.

The success of your project depends on selecting the right CNC machining service provider. Explore essential tips and criteria to make an informed decision. Ready to make the right choice for your machining needs? Let's get you started!

When it comes to CNC machining for your machined wheels or other precision components, the choice of the machining supplier is crucial. Here are some key factors to consider when evaluating potential suppliers:

Experience and Expertise: Look for a supplier with a proven track record and extensive experience in CNC machining. A seasoned supplier is more likely to provide high-quality results.

Facility and Equipment: Assess the supplier's facility and equipment. State-of-the-art CNC machines and a well-equipped facility are indicators of the supplier's commitment to precision.

Material Selection: Ensure that the supplier can work with the materials suitable for your project, whether it's aluminum alloy, steel, or other materials.

Quality Control: Inquire about the supplier's quality control processes. Precision components require rigorous inspection to maintain the highest standards.

Customization Capability: If you're looking for customization, verify the supplier's ability to create unique designs and finishes according to your specifications.

Lead Times: Consider the supplier's lead times and delivery schedules. Timely delivery is essential, especially for automotive manufacturers.

References and Reviews: Seek references and read reviews from previous clients to gauge the supplier's reputation and reliability.

When it comes to choosing a CNC precision machine shop that meets and exceeds these criteria, Richconn stands out as a reliable and trusted partner. Richconn's commitment to precision, quality, and customization makes it a top choice for automotive and industrial needs.

Richconn's CNC machining services offer:

Extensive Experience: With years of experience in CNC machining, Richconn has a proven track record in delivering high-precision components.

State-of-the-Art Facility: Richconn's modern facility is equipped with advanced CNC machines and technology to ensure the highest level of accuracy.

Material Versatility: Whether your project requires aluminum alloy, steel, or other materials, Richconn has the expertise to work with a variety of materials.

Quality Assurance: Richconn maintains stringent quality control processes, ensuring that every component meets the specified requirements.

Customization Options: Richconn's ability to provide custom designs and finishes allows you to achieve the unique appearance and performance you desire.

Reliability: The supplier's reputation is backed by positive references and client reviews, emphasizing its commitment to quality and timeliness.

Selecting Richconn as your CNC machining supplier ensures that your machined wheels or precision components meet the highest standards of quality and precision.

To ensure the longevity of your machined wheels, proper maintenance is crucial. In this section, we'll provide you with insights, tips, and solutions for keeping your wheels in peak condition. Ready to keep your machined wheels looking sharp and performing at their best? Let's dive into the maintenance guide!

Regular cleaning is a fundamental aspect of wheel maintenance. Over time, machined wheels can accumulate dirt, brake dust, and road grime. To keep them looking their best, follow these cleaning tips:

Use a Soft Brush: Avoid abrasive materials that can scratch the wheel's surface. Instead, use a soft-bristle brush to remove loose dirt and debris.

Mild Cleanser: Opt for a mild cleanser or a dedicated wheel cleaner to safely remove stubborn contaminants.

Avoid Harsh Chemicals: Stay away from harsh chemicals that can damage the finish. Acidic cleaners should be avoided.

Rinse Thoroughly: After cleaning, rinse the wheels thoroughly to remove all cleaning residues.

Regular inspections can help you identify any issues with your machined wheels before they become major problems. Here's what to look for during inspections:

Cracks and Damage: Check for any cracks or damage to the wheel's surface. Small cracks can be a precursor to more significant issues.

Air Pressure: Ensure that the air pressure in the tires is at the recommended levels to prevent uneven wear and stress on the wheels.

Alignment: Regularly check the alignment of your vehicle to prevent excessive stress on the wheels and tires.

The finish of your machined wheels plays a significant role in their appearance. To protect the finish, consider the following:

Waxing: Apply a wheel-specific wax to create a protective barrier and enhance the shine.

Powder Coating Maintenance: If your wheels have a powder coat finish, follow the manufacturer's recommendations for maintenance to preserve the finish.

Extreme weather conditions can take a toll on your machined wheels. Here are some seasonal care tips:

**Winter: Protect your wheels from salt and ice by applying a protective sealant. Regularly clean off salt deposits.

**Summer: Shield your wheels from the sun's UV rays to prevent fading of the finish. Use a wheel-specific UV protectant.

For professional maintenance and care, consider utilizing the services of a qualified auto detailing or wheel maintenance expert. They can provide specialized care, including polishing and restoring the finish to its original luster.

By following these maintenance tips and seeking expert services when needed, you can extend the life of your machined wheels and keep them in prime condition for years to come.

With this comprehensive guide to maintaining and extending the life of your machined wheels, you now have the knowledge to ensure that your investment in these precision-crafted components pays off. Whether you're a car enthusiast or a manufacturer, the synergy of CNC machining and machined wheels enhances both aesthetics and performance. Thank you for joining me on this journey, and may your automotive excellence continue to roll on!

How to DIY CNC Machine?November 2, 2023Are you ready to unlock the world of CNC machining from the comfort of your own workshop? In this article, I will guide you through the process of creating your very own DIY CNC machine, step by step. Whether you're a seasoned DIY enthusiast or just starting out, this article will equip you with the knowledge and skills you need to build, operate, and maintain your CNC machine.view

How to DIY CNC Machine?November 2, 2023Are you ready to unlock the world of CNC machining from the comfort of your own workshop? In this article, I will guide you through the process of creating your very own DIY CNC machine, step by step. Whether you're a seasoned DIY enthusiast or just starting out, this article will equip you with the knowledge and skills you need to build, operate, and maintain your CNC machine.view Spot Welder 101: In-Depth Guide of Process and Tips RevealedJanuary 2, 2024What's a spot welder? The article gives you a comprehensive guide to spot welders and shows you how to control spot welders effectively.view

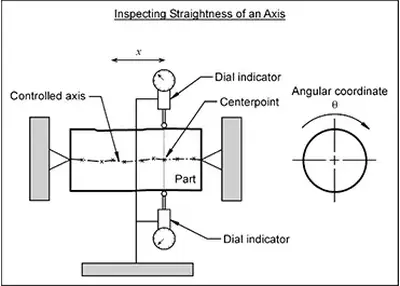

Spot Welder 101: In-Depth Guide of Process and Tips RevealedJanuary 2, 2024What's a spot welder? The article gives you a comprehensive guide to spot welders and shows you how to control spot welders effectively.view Understanding Straightness: Unveiling Precision in EngineeringNovember 21, 2023Welcome to a journey through the realm of straightness—a fundamental concept in the world of engineering and precision manufacturing. Ever wondered how straightness impacts the quality of products or the efficiency of industrial processes? Join me as we explore the nuances and practical applications of this crucial element.view

Understanding Straightness: Unveiling Precision in EngineeringNovember 21, 2023Welcome to a journey through the realm of straightness—a fundamental concept in the world of engineering and precision manufacturing. Ever wondered how straightness impacts the quality of products or the efficiency of industrial processes? Join me as we explore the nuances and practical applications of this crucial element.view How to Choose CNC Machining Service Provider?October 25, 2023This article covers everything you need to know about quality control in your CNC machine shop. It will serve as a guide to help you quickly identify machine shops that you should work with and must avoid.view

How to Choose CNC Machining Service Provider?October 25, 2023This article covers everything you need to know about quality control in your CNC machine shop. It will serve as a guide to help you quickly identify machine shops that you should work with and must avoid.view Precision Engineered CNC Turning PartsSeptember 22, 2023CNC turned parts are a type of mechanical part that is manufactured through numerical control (Computer Numerical Control, CNC) technology.view

Precision Engineered CNC Turning PartsSeptember 22, 2023CNC turned parts are a type of mechanical part that is manufactured through numerical control (Computer Numerical Control, CNC) technology.view Top 12 CNC Machining Manufacturers in the USAJune 8, 2024Looking for reliable CNC machining parts manufacturers in the USA? Check out our list of the top 12 companies, each with its own unique advantages and processing capacities. Find the perfect partner for your business today!view

Top 12 CNC Machining Manufacturers in the USAJune 8, 2024Looking for reliable CNC machining parts manufacturers in the USA? Check out our list of the top 12 companies, each with its own unique advantages and processing capacities. Find the perfect partner for your business today!view