The common forms of failure of mechanical parts are fracture, plastic deformation, excessive elastic deformation, excessive wear or damage to the working surface, the occurrence of strong vibration, the loosening of the coupling, friction drive slippage and so on.

Summarized is the following four types of failure: overall fracture, excessive residual deformation, surface damage to the parts, damage to the normal working conditions caused by failure.

General threaded connection can meet the self-locking conditions and will not be automatically loosened, but in the vibration or shock load, or temperature change is large, the connection nut may be gradually loosened. The main cause of thread loosening is the relative rotation between the threaded parts, so in the actual design, it is necessary to use anti-loosening measures.

1, friction anti-loosening --- to maintain the friction between the threaded vice to prevent loosening, such as adding spring washers, against the top of the double nut;

2、Mechanical anti-loosening --- the use of stop parts to ensure that the anti-loosening, often used in slot nuts and cotter pins and so on;

3、Destruction of threaded sub-preventing loosening --- destroying and changing the relationship of threaded sub-preventing, such as impact method.

The purpose of tightening in the threaded connection is to let the bolt produce preload, the purpose of preload is to enhance the reliability and tightness of the connection, in order to prevent gaps or relative sliding between the connected parts after loading. An effective method to control the tightening force is to measure the torque wrench or fixed torque wrench, when the required torque is reached, locking can be used; or the method of measuring the bolt elongation is used to control the preloading force.

Elastic slip is an inherent characteristic of belt drive and is unavoidable. When there is a tension difference and the belt is an elastomer, elastic sliding occurs. Slipping is caused by overloading and is a form of failure that can and must be avoided.

The reason for this is that slippage occurs on small pulleys. The greater the external load, the greater the difference in tension between the two sides, which leads to an increase in the elastic sliding zone, and slippage occurs when elastic sliding occurs within the wrapped corners. Elastic sliding is a quantitative change, slipping is a qualitative change. Wheel diameter is small, small package angle, friction contact area is small, easy to slip.

Because of gray cast iron and aluminum bronze turbine's main form of failure is tooth gluing, and gluing and sliding speed, so its permissible contact stress and tooth sliding speed.

Cast tin bronze turbine's main form of failure is tooth pitting, which occurs by the contact stress, so the permissible contact stress and sliding speed is not relevant.

Cam mechanism follower commonly used laws of motion for isokinetic law, such as acceleration and deceleration law, the law of simple harmonic motion (cosine acceleration law of motion).

Isokinetic motion law has rigid impact, used for low-speed light load occasions; equal acceleration and other deceleration motion law has flexible impact, used for low-speed occasions; simple harmonic motion law (cosine acceleration law of motion) when there is a stopping interval when there is a flexible impact, used for low-speed occasions, when there is no stopping interval when there is no flexible impact, used for high-speed occasions.

Regardless of the tooth profile in any position contact, over the contact point made by the common normal must pass through the center line on a certain point, in order to ensure that the transmission ratio is constant.

Key connection, spline connection, interference fit connection, set screws, pin connection, expansion connection.

Axial fixation of the shoulder, collar, sleeve, shaft end plate, elastic gear ring, shoulder, collar, sleeve fixed and reliable, can withstand large axial force; elastic gear fixed can withstand smaller axial force; shaft end plate for the fixation of shaft parts.

Worm gearing exists relative sliding, friction, and because of the closed worm gearing heat dissipation is poor, easy to produce glue, so the heat balance calculation.

The calculation of contact fatigue strength of tooth face and bending fatigue strength of tooth root, the contact fatigue strength of tooth face for fatigue pitting failure of tooth face and bending fatigue strength of tooth root for fatigue fracture of tooth root. Gear transmission for the closed soft gear transmission, the design guidelines are based on the contact fatigue strength of the tooth face design, check the bending fatigue strength of the tooth root.

Coupling and clutch function is to connect the two shafts so that one of the same rotation and transfer torque. The difference between the two is: coupling coupling of the two shafts in the work can not be separated, only in the shutdown after the disassembly of parts can be separated from the two shafts, and with the clutch can be in the process of machine operation at any time to separate or engage the two shafts.

1. A wedge-shaped gap must be formed between two surfaces in relative motion.

2. the two surfaces separated by the oil film must have a certain relative sliding speed, the direction of which should be to ensure that the lubricant from the large mouth in, out of the small mouth. 3;

3. The lubricant must have a certain viscosity and the oil supply must be sufficient.

Code meaning: 7 - angular contact ball bearings; (0) - normal width, 0 can be omitted; 3 - diameter series for the series; 10 --The inner diameter of the bearing is 50mm.

Characteristics and applications: can withstand both radial load and unidirectional axial load, high limiting speed, generally used in pairs.

Generally, the belt drive is arranged in the highest level, the chain drive is arranged in the lowest level; the belt drive has a smooth transmission, cushioning and vibration absorption characteristics, so it is placed in the high speed level, which is beneficial to the motor; the chain drive is noisy at work, and it is suitable for working in the lower speed occasions, so it is generally arranged in the low-speed level.

1. The main reason for the uneven speed of chain drive is the polygonal effect of chain drive. 2;

2. the main influencing factors are the speed of the chain, the pitch of the chain and the number of teeth of the sprocket;

3. in the size of the sprocket teeth equal z1 = z2 (i.e. R1 = R2), and transmission of the center of the distance is precisely an integer multiple of the pitch p, the instantaneous transmission ratio is constant, that is, constant 1.

1. The pinion tooth width b1 is slightly larger than the large gear tooth width b2 in order to prevent the working load from being increased due to the reduction of the meshing tooth width as a result of axial misalignment of the large and small gears caused by assembly errors.

2. The tooth width coefficient ψd is calculated according to the large gear tooth width b2; because the large gear tooth width b2 is the actual contact width when a pair of cylindrical gears mesh.

1. The smaller the pulley diameter, the greater the bending stress on the belt, so in order to avoid excessive bending stress on the belt, the minimum diameter of the pulley should be limited. 2;

2. The wrapping angle α1 of the main pulley affects the maximum effective pulling force of the belt, the smaller α1 is, the smaller the maximum effective pulling force of the belt is, in order to increase the maximum effective pulling force of the belt drive and to prevent slipping, generally α1 ≥ 120°;

3. belt speed is too small that the diameter of the small pulley is too small, will make the required effective tension Fe is too large, resulting in too many roots of the belt z, making the structure of the belt drive becomes larger; belt speed is too large is too large centrifugal force Fc, so the belt speed should be in the (5 ~ 25) m/s.

Advantages: 1. little wear and tear, can also be adjusted to eliminate the gap and produce a certain pre-deformation to increase the stiffness, so its transmission precision is very high, 2. not self-locking, can be changed from linear to rotary motion.

Disadvantages: 1. complex structure, manufacturing difficulties, 2. some institutions in order to prevent the reversal of the need to add another self-locking mechanism.

Type selection and size selection of two aspects: type selection should be based on the structural characteristics of the key connection, the use of requirements and working conditions selection Size selection should be in accordance with the standard specifications and strength requirements to be taken in accordance with the size of the key for the cross-sectional dimensions (key width b * key height h) and the length of the L, cross-sectional dimensions of the b * h by the diameter of the shaft d by the standard selected, the length of the key L generally according to the length of the wheel hub, i.e., the length of the key L ≦ wheel hub length The length L of the key can be generally determined by the length of the hub, i.e. key length L≦hub length, while the guiding flat key can be determined by the length of the hub and the sliding distance, generally hub length L'≈(1.5-2)*d.

The field of machining involves a number of important concepts and principles, and Richconn has the experience and expertise as a rapid prototyping companies to provide precision CNC turning services, CNC milling services, and custom sheet metal services to ensure that your mechanical parts are machined and manufactured with high quality.

In machining, it is crucial to understand the forms of failure of mechanical parts, including fracture, plastic deformation, wear, and vibration, which helps in the design and maintenance of mechanical components.

In addition, threaded couplings are common connections in machinery, and an understanding of the principles and methods of anti-loosening, such as friction anti-loosening, mechanical anti-loosening, and destruction of threaded pairs anti-loosening, is essential to ensure the reliability of the coupling.

Knowledge of the purpose of tightening and methods of controlling tightening forces helps in the assembly of machinery and ensures a strong connection between mechanical components.

When designing a belt drive, understanding the minimum diameter requirements for small pulleys is essential to prevent slippage and ensure drive reliability.

Richconn's precision fabrication services can fulfill your machining needs, ensuring high quality and reliability of your mechanical components. Whether you need cnc machining services, custom sheet metal fabrication, or other precision manufacturing services, Richconn has the expertise to support you.

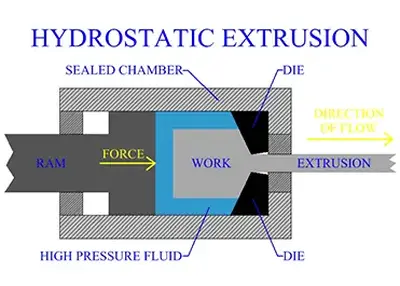

Extrusion: A Manufacturing Process for Creating Various Shapes and ProductsNovember 30, 2023what is extrusion?Extrusion is a process of forcing a material through a die or a nozzle to create a continuous shape or product. The material can be solid, liquid, or semi-solid, and it can be metal,...view

Extrusion: A Manufacturing Process for Creating Various Shapes and ProductsNovember 30, 2023what is extrusion?Extrusion is a process of forcing a material through a die or a nozzle to create a continuous shape or product. The material can be solid, liquid, or semi-solid, and it can be metal,...view The Complete Guide to CNC Machining Parts: Types, Advantages & DesignApril 3, 2024The following is a thorough introduction to CNC machining parts, which is of great importance for your project. Let’s have a deeper look at these machined parts!view

The Complete Guide to CNC Machining Parts: Types, Advantages & DesignApril 3, 2024The following is a thorough introduction to CNC machining parts, which is of great importance for your project. Let’s have a deeper look at these machined parts!view The Glass Transition Temperature of PolymersOctober 17, 2023When designing parts for plastic injection molding, there is an important but often overlooked material consideration. It involves the glass transition temperature, or Tg. We'll get into the underlying science later, but for now, keep in mind that there is a temperature at which amorphous materials transition from a glassy/rigid state to a leathery/rubbery state.view

The Glass Transition Temperature of PolymersOctober 17, 2023When designing parts for plastic injection molding, there is an important but often overlooked material consideration. It involves the glass transition temperature, or Tg. We'll get into the underlying science later, but for now, keep in mind that there is a temperature at which amorphous materials transition from a glassy/rigid state to a leathery/rubbery state.view Understanding machining tools: types, uses and selectionNovember 1, 2023Machining tools are vital tools in manufacturing, used to cut, chip, grind and shape a wide range of materials, from metals to plastics to wood. Different tool types are used for different processes and materials to meet a variety of machining needs. Below are five common types of machining tools that are used in a wide range of manufacturing and processing applications.view

Understanding machining tools: types, uses and selectionNovember 1, 2023Machining tools are vital tools in manufacturing, used to cut, chip, grind and shape a wide range of materials, from metals to plastics to wood. Different tool types are used for different processes and materials to meet a variety of machining needs. Below are five common types of machining tools that are used in a wide range of manufacturing and processing applications.view Some Knowledge You Need to Learn About Tapped HoleNovember 16, 2023Do you need taped holes? This article covers the factors you must consider to manufacture the tapped hole during the process.view

Some Knowledge You Need to Learn About Tapped HoleNovember 16, 2023Do you need taped holes? This article covers the factors you must consider to manufacture the tapped hole during the process.view Dual-tone Baking Paint Technology: Achieving Unique Visual EffectsJuly 31, 2023Have you seen two-tone colored cars, phones, appliances, buildings? Want to understand how to achieve two-tone baked paint? This article introduces this unique parts painting technique in detail, expl...view

Dual-tone Baking Paint Technology: Achieving Unique Visual EffectsJuly 31, 2023Have you seen two-tone colored cars, phones, appliances, buildings? Want to understand how to achieve two-tone baked paint? This article introduces this unique parts painting technique in detail, expl...view