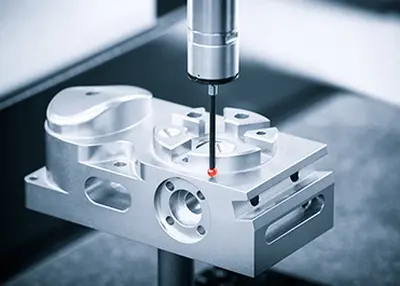

When it comes to cnc machining services, you will definitely think of 5-axis CNC machining. Choosing the right machining solution will lead to a successful production. CNC machining is a procedure used in most manufacturing operations and is widely used in most industries. CNC stands for Computer Numerical Control and deals with the use of one or more computers to manage the operation of different machine tools.

5-axis CNC machining is an absolutely excellent CNC machining for producing parts and final products from a wide variety of materials such as plastics and metals. However, when it comes to specific 5-axis CNC machining, most people's first impression is: high technology, expensive, and difficult to operate, but is 5-axis machining really like this? The following paragraphs will introduce you to 5-axis CNC service machining from 3 important aspects.

Five-axis CNC service is a procedure that involves using a CNC to move a cutting device or different parts in five different axes at the same time. This makes room for producing very complex parts, which is why 5-axis CNC milling is very common in aerospace operations. One of the biggest contributors to the use of 5-axis CNC machines is the need to increase proficiency and reduce the production time required from the start of the actual process to completion. The ability to avoid collisions with parts of stationary equipment by rotating the table or cutting tool to provide space for rapid access to part geometry is another contributing factor. Finally, improve equipment life or life by rotating the table or cutting equipment to maintain optimal cutting position and consistent chip loading.

Five-axis CNC service machining is a way of OEM precision CNC machining. The machining centre we usually use is a three-axis machining centre. The 3-axis refers to the X-axis, Y-axis, and Z-axis of the machining center. The five-axis machining center is to add two rotary axes to the three common linear axes of X, Y, and Z, which are also called the fourth axis and the fifth axis. Two of the three axes A, B, and C have different movement modes in the vertical machine to meet the technical needs of various products.

There are many types of five-axis machine tools for horizontal machining centers, mainly in the following five forms: one is the double rotary head form, two rotating coordinates directly control the direction of the tool axis; the other is the drooping rotary head form, the two coordinate axes are at the top of the tool , but the rotation axis is not perpendicular to the linear axis; the third is the double turntable form, the two rotation coordinates directly control the space rotation; the fourth is the sagging worktable, the two axes are on the worktable, but the rotation axis is not perpendicular to the axis; the fifth is one swing and one turn, two rotation coordinates, one on the tool and one on the workpiece.

There are several operations that allow a 5-axis CNC service machine to save you a lot of time and enhance your current programs. These machines come in a variety of types to meet the demands of the growing manufacturing industry. A unique difference to a 5-axis CNC machine is the arrangement of the rotary axes.

The Creative Masters' Secret Weapon: The Process and Application of Two-Tone ElectroplatingAugust 1, 2023Two-tone electroplating is a common surface treatment process we see, used on many products or parts. Want to understand how to achieve two-tone electroplating? This article introduces this unique par...view

The Creative Masters' Secret Weapon: The Process and Application of Two-Tone ElectroplatingAugust 1, 2023Two-tone electroplating is a common surface treatment process we see, used on many products or parts. Want to understand how to achieve two-tone electroplating? This article introduces this unique par...view Basic Parts of CNC Lathe and Their MaintenanceOctober 20, 2023CNC lathes and steering centers are highly accurate and efficient automatic machine tools. The machine is equipped with a multi-station turret or power turret for a wide range of machining capabilities. It can handle linear cylinders, tilting cylinders, arcs and a variety of complex workpieces such as threads, grooves, worms, etc.view

Basic Parts of CNC Lathe and Their MaintenanceOctober 20, 2023CNC lathes and steering centers are highly accurate and efficient automatic machine tools. The machine is equipped with a multi-station turret or power turret for a wide range of machining capabilities. It can handle linear cylinders, tilting cylinders, arcs and a variety of complex workpieces such as threads, grooves, worms, etc.view CNC Machining and 3D Printing for Metal PartsOctober 18, 2023Are you designing metal parts? When you add metal CNC machining and 3D printing to your repertoire of manufacturing tools, you're not just more flexible when it comes to part design. You can also source them in less time and at a lower cost than ever before.view

CNC Machining and 3D Printing for Metal PartsOctober 18, 2023Are you designing metal parts? When you add metal CNC machining and 3D printing to your repertoire of manufacturing tools, you're not just more flexible when it comes to part design. You can also source them in less time and at a lower cost than ever before.view Titanium vs Steel: Is Titanium Stronger Than Steel?August 29, 2023Is titanium stronger than steel? Here's a brief guide that compares steel to titanium from different aspects.view

Titanium vs Steel: Is Titanium Stronger Than Steel?August 29, 2023Is titanium stronger than steel? Here's a brief guide that compares steel to titanium from different aspects.view The Glass Transition Temperature of PolymersOctober 17, 2023When designing parts for plastic injection molding, there is an important but often overlooked material consideration. It involves the glass transition temperature, or Tg. We'll get into the underlying science later, but for now, keep in mind that there is a temperature at which amorphous materials transition from a glassy/rigid state to a leathery/rubbery state.view

The Glass Transition Temperature of PolymersOctober 17, 2023When designing parts for plastic injection molding, there is an important but often overlooked material consideration. It involves the glass transition temperature, or Tg. We'll get into the underlying science later, but for now, keep in mind that there is a temperature at which amorphous materials transition from a glassy/rigid state to a leathery/rubbery state.view What Are the Characteristics of the Surface Treatment Process for Titanium Alloy Materials?October 30, 2023Titanium alloys are a variety of alloy metals made of titanium and other metals, which are relatively scarce and expensive; titanium alloys are characterized by high strength, light weight, corrosion resistance and high temperature resistance, and can be used in a variety of fine chemicals, which are mainly used in the automotive industry, aerospace, nuclear industry, chemical and petrochemical industries, dentistry and medical restoration and other fields.view

What Are the Characteristics of the Surface Treatment Process for Titanium Alloy Materials?October 30, 2023Titanium alloys are a variety of alloy metals made of titanium and other metals, which are relatively scarce and expensive; titanium alloys are characterized by high strength, light weight, corrosion resistance and high temperature resistance, and can be used in a variety of fine chemicals, which are mainly used in the automotive industry, aerospace, nuclear industry, chemical and petrochemical industries, dentistry and medical restoration and other fields.view

EN

EN

ru

ru