CNC machines have become increasingly popular in various industries due to their precision and efficiency. They are manufacturing different parts and fittings in a wide range of industries, such as automotive, aerospace, electronics, and medical equipment manufacturing. No matter you want to know more about what is CNC machine or would like to get more information on how to choose CNC machine service, you have come to the right place!

CNC machining services use fast, repeatable, and programmable machines to manufacture components with precision and accuracy. CNC machining is capable of performing complex tasks like cutting, drilling, milling, and shaping materials like metal, wood, or plastic, making them a popular choice for applications in a wide range of industries, including aerospace, automotive, medical devices, and consumer goods.

CNC Machining Services are always prepared to meet the demands of tight tolerances and complex CNC machined products. Generally, the more complex a design is, the more high-precision of CNC machining services it will need. Here is a brief introduction to CNC machine services:

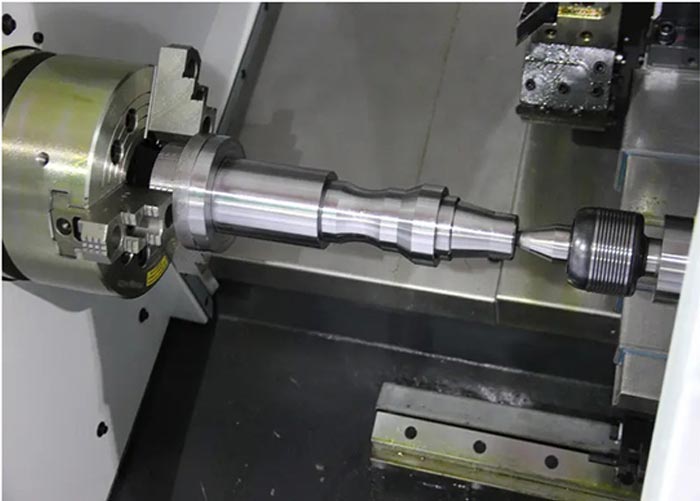

Overview of CNC Turning

CNC turning, an accuracy and precision machining process, creates cylindrical parts by removing material from a rotating workpiece. CNC turning is quite simple. This process involves the use of a lathe machine equipped with computer-controlled tools that precisely cut and shape the workpiece according to programmed instructions.

Advantages of CNC Turning

1. Precision and Accuracy

CNC turning is a common process in the manufacture of various metal parts with precision and accuracy such as engine parts, shafts, bushings, and gears.

2. Consistency, Repeatability, and Efficiency

Compared with typical manual turning, CNC turning has several advantages when manufacturing components including consistency, repeatability, and efficiency.

Application of CNC Turning

CNC turning can be adopted in manufacturing different parts and fittings in a wide range of industries such as automotive, aerospace, electronics, and medical device manufacturing. In the automotive industry, CNC turning is used to create engine components, transmission parts, and other critical components. In aerospace manufacturing, it is utilized for producing turbine blades, landing gear components, and structural parts.

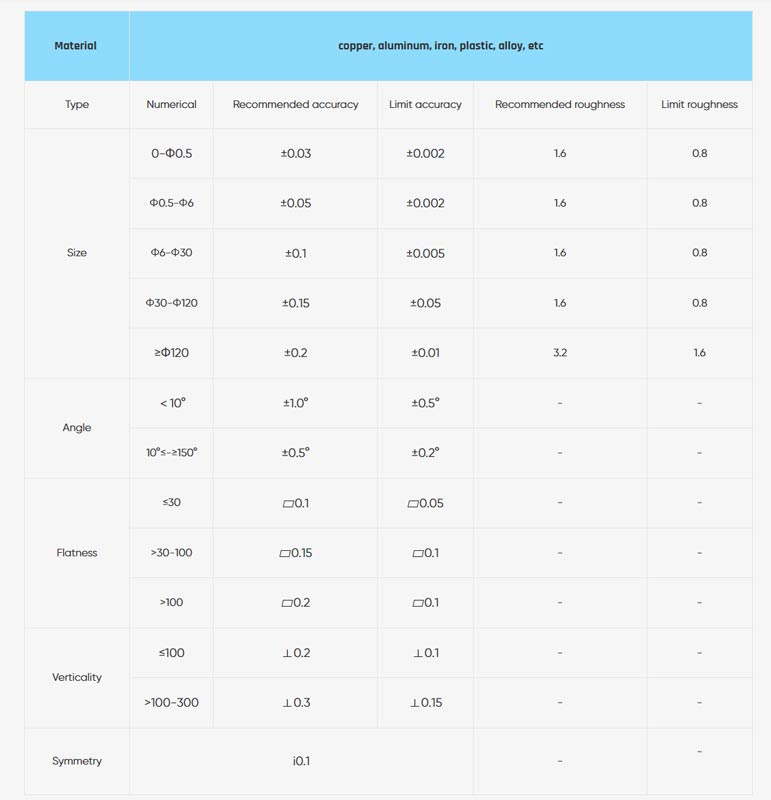

Guidance for CNC Turning Design by Richconn

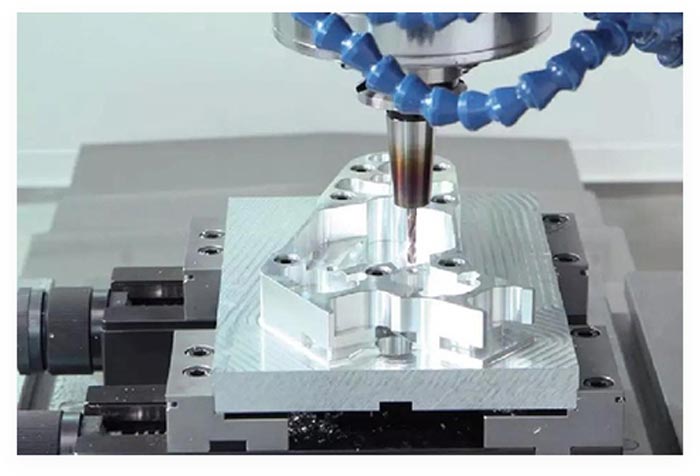

Overview of CNC Milling

CNC milling is a machining process that utilizes computerized controls and rotating multi-point cutting tools to remove material from a workpiece. One of the features of the CNC milling process is that the workpiece remains stable and the cutting tools can be rotated at high speeds to produce precise cuts and shapes.

Advantages of CNC Milling

1. Cost-efficient

Our CNC milling is extremely cost-efficient for mass production. Metal parts can be CNC milled in a few minutes or even seconds by optimizing the tool paths and using some cutting tools.

2. Materials Options

CMC milling can be used to create parts from various materials such as metals, plastics, and composites.

Application of CNC Milling

CNC milling machining is appropriate for general-purpose parts and components such as gears and shafts, nuts and bolts, and flanges. Furthermore, it is appropriate for both large-scale and short-term production. CNC milling is also applicable in making many aeronautic components using materials such as Titanium and Aluminum because the material in aeronautics requires lightweight and durability.

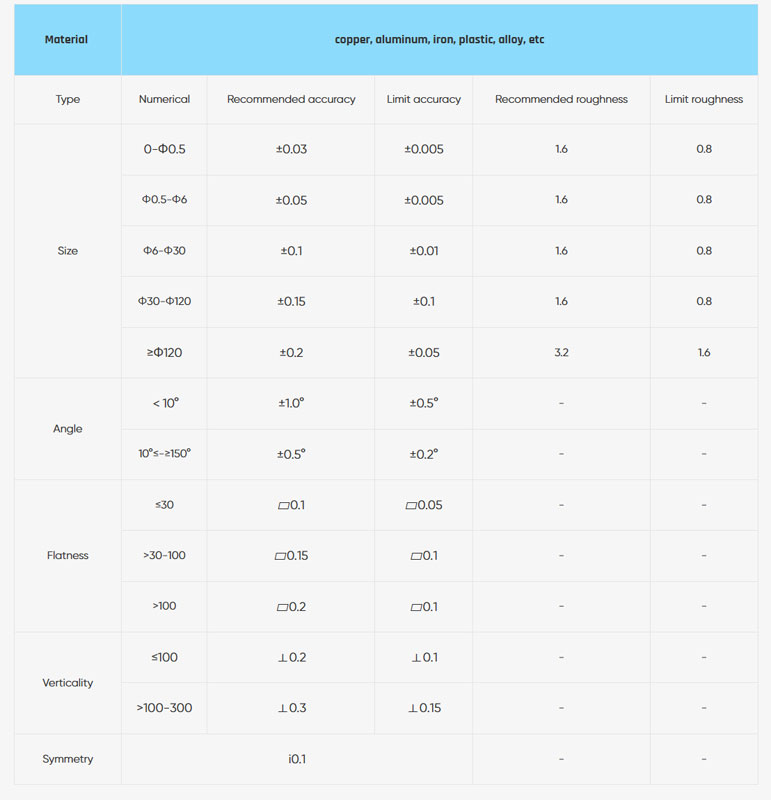

Guidance for CNC Milling Design by Richconn

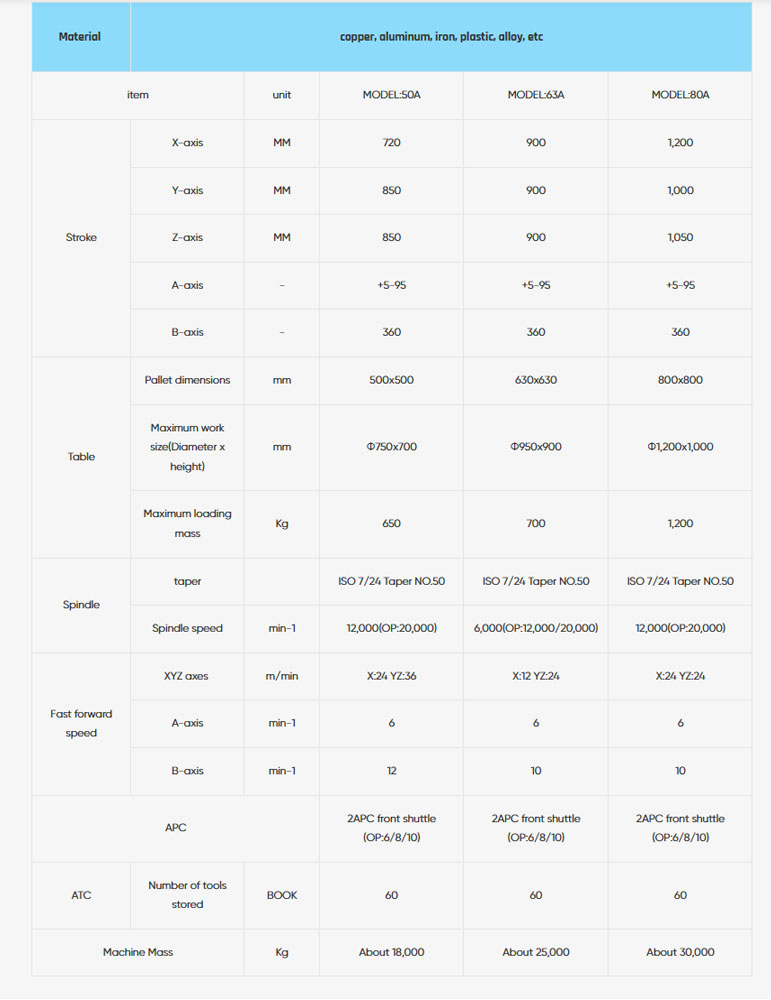

Overview of 4-axis CNC Machining

4 Axis CNC machining refers to the process of using a CNC machine to create complex and intricate parts on a workpiece. Unlike traditional machining methods,

4 Axis CNC machining consists of three axes (X, Y, and Z), and an additional rotational axis.

Overview of 5-axis CNC Machining

5 Axis CNC machining involves three typical axes of movement (X, Y, and Z), 5-axis CNC machining allows for two additional rotational axes (A and B).

Advantages of 4-axis & 5-axis CNC Machining

1. High-precision Production

4-Axis & 5-Axis machine services are unrivaled in terms of speed and flexibility. We have the ability to offer the best-machined components because of a comprehensive selection of modern 4-Axis or 5-axis CNC machines and a long list of materials.

2. Short Lead Time

Our skilled staff and manufacturing skills help in the rapid design and fabrication of complex, time-sensitive components.

Application of 4-axis & 5-axis CNC Machining

4-Axis & 5-Axis CNC Machine services are your best choice when it comes to producing high-precision and complexity fittings within a wide range of industries. Our manufacturing capabilities allow us to produce several components efficiently.

Guidance for 4-axis CNC Machining Design by Richconn

Guidance for 5-axis CNC Machining Design by Richconn

As one of the leading CNC machining companies in China, Richconn provides a variety of CNC machining services including milling, turning, 4-Axis & 5-Axis CNC Machining. Whether you need prototype machining or machining parts manufacturing, Richconn CNC machining service will be your best choice.

√ Cost-effective

Purchasing and maintaining CNC machines demands significant resources that medium-sized companies can't spend. Richconn, the best CNC machining service supplier, offers prototype machining or machining parts manufacturing beyond your expectation at a lower price.

√ Instant quotes

We offer a precision CNC services platform, combined with other advanced capabilities, and our experienced team provide a faster ordering process for precision CNC machining.

√ Short lead time

We have Chinese workshops and state-of-the-art machinery to help you get your prototype CNC machining or OEM CNC machining parts faster.

√ Precision CNC machining

Taking precision 4- and 5-axis CNC machining as an example, we can handle all types of CNC machining parts in both metal and plastic materials.

Don't hesitate to get your custom CNC machining services NOW >>>

Click it ⬇⬇⬇

With the above ultimate guide, we hope you can have a comprehensive understanding of our CNC machining services. If you are looking for a reliable partner for CNC machining, Richconn could be your best pick. Richconn's professional service ensures that you can choose the most suitable and cost-effective CNC machining. So, contact us and get instant quote today!

What Will Determine the Precision of CNC Machining?August 10, 2022In the preparation of CNC machining programs, proper use of methods and techniques is of great significance to ensure and improve the machining accuracy of CNC machine tools. So what determines the ma...view

What Will Determine the Precision of CNC Machining?August 10, 2022In the preparation of CNC machining programs, proper use of methods and techniques is of great significance to ensure and improve the machining accuracy of CNC machine tools. So what determines the ma...view The Basics of Engineering Drawing and Tips for NewcomersApril 7, 2024The article gives some useful tips on how to make engineering drawings easily to help you better communicate your ideas clearly.view

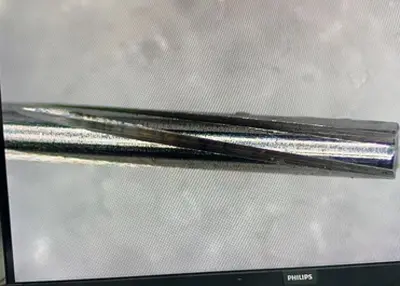

The Basics of Engineering Drawing and Tips for NewcomersApril 7, 2024The article gives some useful tips on how to make engineering drawings easily to help you better communicate your ideas clearly.view Case Study 2023: Improving the Yield of Precision Mandrel Parts ProductsDecember 22, 2023Key production process design and high-quality processing give us the basic characteristics that customers like, and we can also provide you with the services you need.view

Case Study 2023: Improving the Yield of Precision Mandrel Parts ProductsDecember 22, 2023Key production process design and high-quality processing give us the basic characteristics that customers like, and we can also provide you with the services you need.view The Importance of Material Science in Component Interaction.October 18, 2023Even a perfectly designed injection molded part can potentially disappoint if it is made from the wrong material. It is often difficult to select the right materials from hundreds of thermoplastics and elastomers to meet the requirements of the application. A variety of factors, such as mechanical strength, UV resistance, lubricity, wear resistance, and chemical and UV resistance should be carefully considered when selecting materials for injection molding.view

The Importance of Material Science in Component Interaction.October 18, 2023Even a perfectly designed injection molded part can potentially disappoint if it is made from the wrong material. It is often difficult to select the right materials from hundreds of thermoplastics and elastomers to meet the requirements of the application. A variety of factors, such as mechanical strength, UV resistance, lubricity, wear resistance, and chemical and UV resistance should be carefully considered when selecting materials for injection molding.view Welding vs. Riveting: Differences, Advantages and DisadvantagesNovember 28, 2023Metal joining is a process of attaching or combining two or more metal pieces or parts together. Metal joining is essential for various industries, such as construction, automotive, aerospace, and manufacturing.view

Welding vs. Riveting: Differences, Advantages and DisadvantagesNovember 28, 2023Metal joining is a process of attaching or combining two or more metal pieces or parts together. Metal joining is essential for various industries, such as construction, automotive, aerospace, and manufacturing.view Introduction to MetalworkingOctober 24, 2023Humans have developed many methods of metal fabrication, which is the processing of metal into various shape types. Here we will introduce some of the concepts and processes of this metal working method.view

Introduction to MetalworkingOctober 24, 2023Humans have developed many methods of metal fabrication, which is the processing of metal into various shape types. Here we will introduce some of the concepts and processes of this metal working method.view

EN

EN

ru

ru