Unlocking the Secrets of Machined Eye Bolts for Precision and Durability

When it comes to precision engineering and safety, there's no room for compromise. Whether you are involved in industrial operations, construction, aerospace, or recreational equipment, the quality of your components is paramount. Enter Machined Eye Bolts, the unsung heroes that bear the weight of your projects, ensuring safety and performance.

In this comprehensive guide, I'm here to shed light on Machined Eye Bolts, unraveling their significance, manufacturing processes, diverse applications, and how to make informed choices. Richconn, the name synonymous with quality and precision, is at your service to provide you with the best solutions in the industry.

Defining Excellence in Engineering

Machined Eye Bolts are the backbone of numerous industrial, construction, and recreational applications. These small but mighty components are designed to withstand substantial loads while ensuring secure attachment points. They're the unsung heroes that keep things together when it matters most.

Machined Eye Bolts are typically made from materials such as carbon steel, stainless steel, or other high-strength alloys. These materials are chosen for their durability, corrosion resistance, and load-bearing capabilities.

Crafting Quality with Precision

Selecting the Right Materials

Precision starts with material selection. High-quality steel, stainless steel, and other materials ensure the longevity and performance of Machined Eye Bolts. The table below provides a comparative overview of the most common materials used for Machined Eye Bolts:

| Material | Properties | Applications |

|---|---|---|

| Carbon Steel | High strength, cost-effective | General industrial use |

| Stainless Steel | Corrosion-resistant, ideal for wet environments | Marine and food industry |

| Alloy Steel | Exceptional strength and durability | Heavy machinery |

Each material offers specific advantages, so choosing the right one depends on your application's requirements.

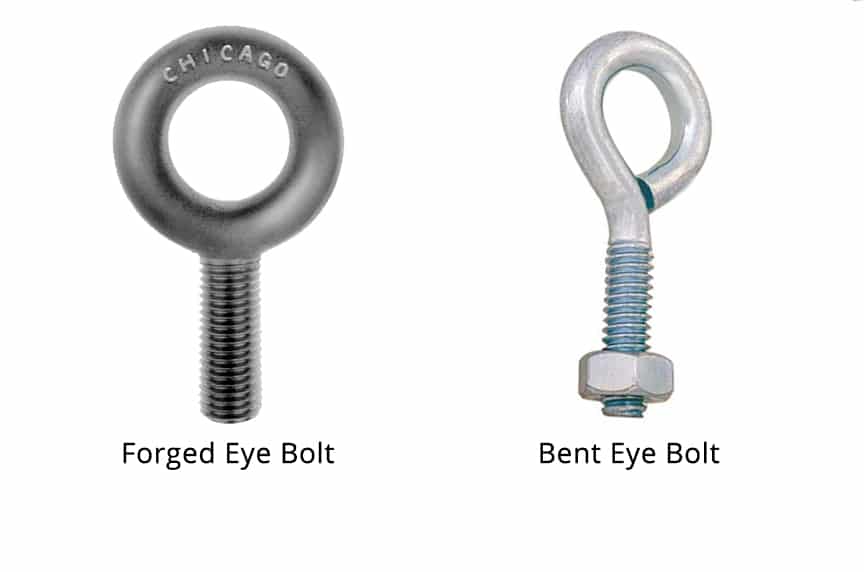

The Machining Process

Dive into the intricacies of the manufacturing process. CNC machining and forging techniques create precise threads, smooth surfaces, and consistent quality. The following table outlines the key steps involved in machining Machined Eye Bolts:

| Manufacturing Step | Description |

|---|---|

| Material Selection | Choose the appropriate material for the Eye Bolts. |

| CNC Machining | Precision cutting and shaping of the Eye Bolts. |

| Forging | Forming Eye Bolts through heating and shaping metal. |

| Threading | Creating threads on the Eye Bolts for attachments. |

| Surface Finishing | Applying coatings or treatments for corrosion resistance. |

The combination of these steps results in Machined Eye Bolts that meet stringent quality standards.

Quality Control Matters

We'll explore the stringent quality control measures that guarantee Machined Eye Bolts meet or exceed industry standards. Rigorous testing for load capacity, material integrity, and dimensional accuracy ensures that each Eye Bolt is reliable and safe for use.

Certification and Compliance

Understand the importance of certifications and compliance with industry regulations to ensure safety and reliability. Many Eye Bolts come with certifications, such as CE or ANSI/ASME standards compliance, indicating that they meet specific safety and performance requirements.

The Versatility of Machined Eye Bolts

Industrial Applications

Machined Eye Bolts are workhorses in various industrial applications. Their reliability and load-bearing capacity make them essential for heavy machinery, material handling, and other industrial processes. These Eye Bolts are used for lifting, securing loads, and creating anchor points in manufacturing facilities. Here are some specific use cases in the industrial sector:

| Application | Description |

|---|---|

| Lifting and Rigging | Eye Bolts are integral components for lifting heavy loads securely. |

| Conveyor Systems | Used for creating attachment points in conveyor systems. |

| Equipment Suspension | Suspension systems in factories often rely on Eye Bolts. |

| Machinery Installation | Eye Bolts play a vital role in securing machinery during installation. |

Construction and Building Projects

In the construction industry, safety is paramount. Machined Eye Bolts contribute to the stability of structures, ensuring that buildings, bridges, and other construction projects meet safety standards. These applications include:

| Application | Description |

|---|---|

| Concrete Formwork | Eye Bolts are used to secure formwork during concrete pouring. |

| Scaffolding | They serve as anchor points for securing scaffolding. |

| Fall Arrest Systems | Eye Bolts are part of fall arrest systems, protecting workers at height. |

| Roofing and Truss Systems | Securing roofing materials and trusses for structural integrity. |

Aerospace and Automotive Industries

Precision and reliability are non-negotiable in the aerospace and automotive sectors. Machined Eye Bolts are integral to the assembly, maintenance, and safety of aircraft and vehicles. Key applications include:

| Application | Description |

|---|---|

| Aircraft Maintenance | Eye Bolts are used for securing components during maintenance. |

| Vehicle Towing and Recovery | Used for attachment points in towing and recovery systems. |

| Aerospace Manufacturing | Essential for assembling aircraft components securely. |

| Vehicle Manufacturing | Eye Bolts assist in the assembly and secure transportation of vehicles. |

Sports and Recreation Equipment

Even in leisure and recreation, safety remains essential. Machined Eye Bolts find their place in various sports and recreational equipment, ensuring the well-being of users. Notable applications include:

| Application | Description |

|---|---|

| Climbing and Mountaineering | Used in climbing anchors and harness systems. |

| Swing and Playground Sets | Eye Bolts secure swings, zip lines, and other play equipment. |

| Water Sports Equipment | Essential for watercraft anchoring and safety systems. |

| Gymnastic Equipment | Used in gymnastic equipment setups for stability. |

These applications showcase the versatility and importance of Machined Eye Bolts in diverse industries. They provide the stability and reliability required for various operations, ensuring the safety and performance of equipment and structures.

Tailoring Your Selection to Your Needs

Considering Purpose and Environment

When choosing Machined Eye Bolts, it's essential to consider the specific purpose and the environment in which they will be used. Different applications and environments require different features and materials. Here are some considerations to keep in mind:

Indoor vs. Outdoor Use: If the Eye Bolts will be exposed to the elements, consider materials with excellent corrosion resistance, such as stainless steel.

Chemical Exposure: In environments with chemicals or corrosive substances, select materials that can withstand chemical exposure without degradation.

High Moisture Areas: Areas with high moisture levels require materials that resist rust and corrosion.

Temperature Extremes: In extreme temperatures, materials with high-temperature resistance may be necessary.

Load Requirements

Understanding the load capacity of Machined Eye Bolts is crucial for safety. Here's how to calculate and select Eye Bolts based on your specific load requirements:

Working Load Limit (WLL): Determine the maximum load that an Eye Bolt can safely handle. Ensure that the WLL of the selected Eye Bolt exceeds the expected load.

Angle of the Load: The angle at which the load is applied affects the load capacity. It's essential to consider this angle when calculating the load.

Number of Eye Bolts: For heavy loads, you may need to use multiple Eye Bolts to distribute the load evenly.

Materials and Specifications

Material selection and sizing guide are critical factors when choosing the right Machined Eye Bolts. Various materials and specifications are available to meet your unique needs. Here's an in-depth look:

| Size (Diameter) | Thread Type | Common Uses |

|---|---|---|

| 1/4" | UNC, UNF | Light-duty applications |

| 3/8" | UNC, UNF | General-purpose use |

| 1/2" | UNC, UNF, metric | Medium-duty applications |

| 5/8" | UNC, UNF, metric | Medium to heavy-duty use |

| 3/4" | UNC, UNF, metric | Heavy-duty applications |

Ensure you select the right size and threading to match your load requirements and intended use.

Materials: As discussed earlier, Eye Bolts are commonly made from carbon steel, stainless steel, and alloy steel. Stainless steel is particularly suitable for applications requiring corrosion resistance, while alloy steel provides exceptional strength.

Sizing and Threads: Eye Bolts come in various sizes and thread types. The size and threading must match your specific application. The table below offers a quick reference to standard sizing:

Choosing the right Machined Eye Bolts is vital for safety, performance, and the longevity of your equipment or structures. Each application may have specific needs, so it's crucial to tailor your selection to meet those requirements.

Preserving Precision and Security

Safety Guidelines

Safety should always be a top priority when using Machined Eye Bolts. Here are some essential safety guidelines to follow:

The correct installation of Machined Eye Bolts is crucial for their performance and safety. Follow these installation guidelines:

Thread Engagement: Ensure that at least 1.5 times the bolt diameter engages the threads in the receiving hole.

Torque Values: Tighten the Eye Bolt to the manufacturer's specified torque values. Over-tightening can damage the threads and under-tightening can lead to inadequate load capacity.

Use Washers: If recommended, use washers under the nut to prevent surface damage.

Alignment: The Eye Bolt should be properly aligned with the direction of the load. Misalignment can reduce load capacity and lead to failure.

Inspect Regularly: Before each use, inspect the Eye Bolts for any visible signs of damage or wear. If you notice any issues, do not use them.

Working Load Limits: Always ensure that the load applied to the Eye Bolts does not exceed their Working Load Limit (WLL). Exceeding this limit can result in failure.

Correct Angle: Ensure that the load is applied at the correct angle. Misalignment can reduce the Eye Bolt's capacity.

Never Side Load: Avoid side loading, as it can weaken the Eye Bolt and reduce its capacity.

No Overloading: Do not overload the Eye Bolts. Use multiple Eye Bolts if necessary to distribute the load evenly.

Proper Installation Methods

Common Issues and Solutions

While using Machined Eye Bolts, you may encounter common issues. Here are some of these issues and practical solutions:

Corrosion: If you notice signs of corrosion, consider using stainless steel Eye Bolts in corrosive environments. Regularly clean and lubricate the Eye Bolts to prevent rust.

Wear and Tear: Over time, Eye Bolts can wear. Replace any Eye Bolts showing signs of wear or damage to maintain safety.

Misalignment: If the Eye Bolt is misaligned during installation, remove it and reinstall it correctly to ensure it can carry the load effectively.

Improper Torque: If the Eye Bolt was not tightened to the manufacturer's specified torque values during installation, adjust it to the correct torque.

Regular Maintenance and Inspection

To extend the life of your Machined Eye Bolts and ensure ongoing safety, it's essential to perform regular maintenance and inspections. Here's what you should do:

Regular Inspection: Continuously inspect the Eye Bolts for signs of wear, damage, or corrosion.

Lubrication: Lubricate the threads and moving parts to prevent rust and ensure smooth operation.

Retorquing: Periodically retorque the Eye Bolts to the manufacturer's specifications.

Replacement: If an Eye Bolt shows signs of damage or wear that cannot be resolved through maintenance, replace it immediately.

Safety and maintenance are paramount when it comes to Machined Eye Bolts. Following these guidelines and being diligent in inspections and maintenance will ensure that your Eye Bolts maintain their reliability and safety over time.

Navigating the Market

Market Price Trends

Understanding the market price trends for Machined Eye Bolts can help you make informed decisions. Prices can vary based on factors such as material, size, and the supplier. It's essential to stay updated with the latest trends. The table below provides a general overview of the price range for Machined Eye Bolts:

| Material | Size | Price Range |

|---|---|---|

| Carbon Steel | 1/4" - 3/4" | $2 - $15 per unit |

| Stainless Steel | 1/4" - 3/4" | $5 - $25 per unit |

| Alloy Steel | 1/4" - 3/4" | $8 - $30 per unit |

These prices are approximate and may vary depending on market conditions, quantity, and supplier.

Comparing Different Suppliers

When selecting a supplier for your Machined Eye Bolts, it's important to consider factors beyond just price. Here's what to look for when comparing different suppliers:

Quality and Certification: Ensure the supplier provides high-quality Eye Bolts that meet or exceed industry standards. Look for certifications and compliance with relevant regulations.

Variety and Customization: Choose a supplier that offers a wide range of sizes, materials, and customization options to meet your specific needs.

Reputation and Reviews: Research the supplier's reputation in the industry and read customer reviews to gauge their reliability and customer service.

Lead Times: Consider the supplier's lead times and availability. Timely delivery is essential for your projects.

Customer Support: A supplier with excellent customer support can provide guidance, answer your questions, and assist with any issues that may arise.

Real-World Applications

Case Studies

Real-world case studies provide insights into how Machined Eye Bolts have been used in various industries to solve specific challenges. Let's explore a couple of examples:

In a heavy manufacturing facility, the use of stainless steel Machined Eye Bolts played a pivotal role in ensuring the safe and efficient lifting of large machinery components. These Eye Bolts not only withstood the weight but also provided resistance to the corrosive environment of the facility.

A construction project required the secure attachment of formwork for a concrete pour. Machined Eye Bolts were used to anchor the formwork, ensuring that it stayed in place during the concrete placement, resulting in a structurally sound building.

Case Study 2: Construction Excellence

Case Study 1: Industrial Strength

Customer Satisfaction and Feedback

Hearing from satisfied customers can offer valuable insights into the benefits of using Machined Eye Bolts. Here are some testimonials:

John, Industrial Project Manager: "We've been using Richconn's stainless steel Eye Bolts for years, and they've never let us down. Their quality and customer support are top-notch."

Sarah, Construction Supervisor: "The versatility of Machined Eye Bolts has been a game-changer for our construction projects. We've improved safety and efficiency thanks to these reliable components."

Mike, Aerospace Engineer: "In aerospace, precision is paramount. Richconn's Eye Bolts have consistently met our high standards, ensuring the safety and performance of our aircraft."

Richconn's Success Projects

Richconn is known for its commitment to excellence and innovation. Here are a few successful projects that demonstrate our capabilities:

Richconn collaborated with a leading aerospace company to provide customized Eye Bolts that met their unique requirements. The success of this project led to an ongoing partnership.

Richconn's Eye Bolts were instrumental in enhancing safety on a major construction site. By providing secure anchoring solutions, Richconn helped reduce accidents and improve project efficiency.

In the sports and recreation industry, Richconn's expertise led to the development of innovative Eye Bolts that improved the safety and performance of recreational equipment.

Project 3: Sports Equipment Reinvention

Project 2: Construction Site Safety

Project 1: Custom Aerospace Solutions

Why Choose Richconn?

Richconn's Professional Services

Richconn stands out as a trusted provider of Machined Eye Bolts. Our commitment to quality, precision, and safety is unwavering. Our team of experts is dedicated to helping you find the ideal solution for your projects.

Customization Options

We understand that every project is unique. That's why we offer a wide range of sizes, materials, and customization options to tailor our Eye Bolts to your specific needs.

How to Get in Touch

If you're ready to explore the benefits of Machined Eye Bolts for your projects, don't hesitate to reach out to us. Our team is available to answer your questions, provide guidance, and assist you in selecting the right components.

Getting Your Questions Answered

Common Questions Answered

Many individuals have questions about Machined Eye Bolts. Here are answers to some of the most frequently asked questions:

A: Yes, many Machined Eye Bolts are designed for lifting applications. However, it's crucial to follow safety guidelines and choose the right Eye Bolt for your specific lifting needs.

A: Yes, stainless steel Eye Bolts are corrosion-resistant and are ideal for outdoor use, even in wet or marine environments.

A: The load capacity varies depending on the size, material, and design of the Eye Bolts. It's essential to check the manufacturer's specifications for each product.

Q: What is the load capacity of Machined Eye Bolts?

Q: Are stainless steel Eye Bolts suitable for outdoor use?

Q: Can I use Eye Bolts for overhead lifting?

Choosing the Right Eye Bolts

To help you select the ideal Eye Bolts for your applications, we've prepared a step-by-step guide. Follow these steps to ensure you make the right choice:

Step 1: Identify the Purpose: Determine the specific use for the Eye Bolts in your project.

Step 2: Consider the Environment: Take into account the environmental conditions, including exposure to moisture, chemicals, or extreme temperatures.

Step 3: Calculate the Load: Calculate the expected load to ensure that the Eye Bolts meet the necessary load capacity.

Step 4: Select the Right Material: Choose the appropriate material based on your project's requirements.

Step 5: Review Sizing and Threads: Make sure the size and threading of the Eye Bolts match your application.

Richconn's Customer Support

At Richconn, we take pride in providing exceptional customer support. Our team is ready to assist you with any questions, concerns, or custom requirements you may have. Your satisfaction is our priority.

Your Journey Begins Here

With this comprehensive guide, you are now equipped with the knowledge to make informed decisions about Machined Eye Bolts. Whether you need them for industrial, construction, aerospace, or recreational applications, Richconn is here to provide you with precision, quality, and safety. Contact us today to take the first step toward precision engineering and excellence. Your projects deserve nothing less.

Explore the possibilities and unlock the potential of Machined Eye Bolts with Richconn. Your journey to precision engineering and safety begins now.

The Application of CNC Machining in Mechanical Equipment - SheetMay 7, 2024Let’s explore the world of sheet in mechanical equipment! Read this article to discover its importance, applications, manufacturing processes, and more.view

The Application of CNC Machining in Mechanical Equipment - SheetMay 7, 2024Let’s explore the world of sheet in mechanical equipment! Read this article to discover its importance, applications, manufacturing processes, and more.view Unlocking the Secrets of Spline Machining: A Comprehensive GuideNovember 15, 2023In the intricate world of manufacturing, the precision required for creating components like splines demands a deep understanding of machining processes. In this comprehensive guide, we embark on a detailed exploration of the art and science behind spline machining, unraveling its complexities and unveiling the techniques that shape these vital engineering elements.view

Unlocking the Secrets of Spline Machining: A Comprehensive GuideNovember 15, 2023In the intricate world of manufacturing, the precision required for creating components like splines demands a deep understanding of machining processes. In this comprehensive guide, we embark on a detailed exploration of the art and science behind spline machining, unraveling its complexities and unveiling the techniques that shape these vital engineering elements.view Machining Tolerances 101: A Complete Guide to CNC Machining TolerancesApril 24, 2024No CNC machine is 100% accurate. That’s the reason why you need to leave spaces for errors in every design of your project. This is where the CNC machining tolerances come in.view

Machining Tolerances 101: A Complete Guide to CNC Machining TolerancesApril 24, 2024No CNC machine is 100% accurate. That’s the reason why you need to leave spaces for errors in every design of your project. This is where the CNC machining tolerances come in.view The Complete Guide to Aerospace Fasteners 2023August 24, 2023The aerospace fastener is an essential part of aerospace equipment which is the core product of modern aviation industry. The main function of air fasteners is to ensure the safety and stability of ai...view

The Complete Guide to Aerospace Fasteners 2023August 24, 2023The aerospace fastener is an essential part of aerospace equipment which is the core product of modern aviation industry. The main function of air fasteners is to ensure the safety and stability of ai...view What is face milling?November 22, 2023Face milling is a metalworking process that is widely used in manufacturing and machining. It is a process in which the surface of a workpiece is cut by a milling cutter on a milling machine to obtain the desired shape, size and surface quality. Face milling can be used to process a variety of metallic and non-metallic materials, including steel, aluminum, copper, plastics and so on.view

What is face milling?November 22, 2023Face milling is a metalworking process that is widely used in manufacturing and machining. It is a process in which the surface of a workpiece is cut by a milling cutter on a milling machine to obtain the desired shape, size and surface quality. Face milling can be used to process a variety of metallic and non-metallic materials, including steel, aluminum, copper, plastics and so on.view From Start-up to Llarge ManufacturerOctober 10, 2023As a manufacturing startup, your success story starts with proving that your product is marketable. When you prepare for large-scale production, it determines the success or failure of the company, because it is in this situation that you have to invest a lot of money and determine the future direction.view

From Start-up to Llarge ManufacturerOctober 10, 2023As a manufacturing startup, your success story starts with proving that your product is marketable. When you prepare for large-scale production, it determines the success or failure of the company, because it is in this situation that you have to invest a lot of money and determine the future direction.view