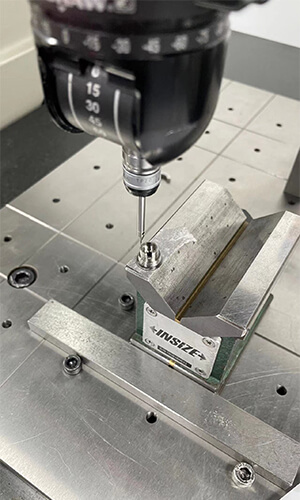

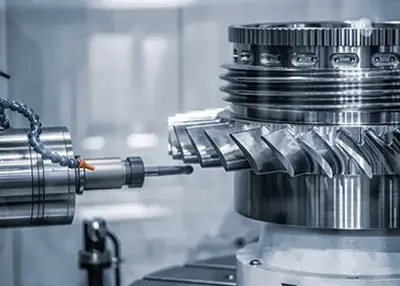

Having advanced five-axis machining centres, Richconn would love to share with you the method of machining titanium alloy special-shaped parts using a five-axis machining centre and the key points of titanium alloy machining.

Titanium alloy processing requires the use of special cooling fluids, which can effectively reduce temperature, reduce wear, and maintain stable machining quality. At the same time, we need to choose special tools suitable for titanium alloy processing to ensure cutting quality and tool life.

When writing machining programs, it is necessary to detail the parameters of each machining step, including cutting speed, feed speed, cutting depth, and feed depth. When machining special-shaped parts, it is especially important to design the cutting path to avoid cutting too deep or too shallow.

In practical machining, it is necessary to adjust the parameters flexibly according to the actual situation to obtain the best machining effect. Generally, titanium alloy processing speed is slower, cutting depth is shallower, and the cutting path needs to be more complex to ensure machining quality and stability.

In addition to the above basic points, the following are some specific numbers and tips for your reference:

Selection of Cooling Fluid

In titanium alloy processing, the selection of cooling fluid is very important. Generally, you can choose titanium alloy special cooling fluids, which have better cooling performance, can effectively reduce tool wear and temperature, and improve processing quality and efficiency.

Cutting Speed and Feed Speed

When machining titanium alloy special-shaped parts, the cutting speed and feed speed need to be adjusted according to specific situations. Generally, the cutting speed is around 60-90m/min, and the feed speed is around 1000-3000mm/min.

Selection of Tools

When choosing titanium alloy tools, it is necessary to consider factors such as tool hardness, wear resistance, and high temperature resistance. Generally, coated tools and alloy tools can be selected, which have better hardness and wear resistance.

Design of Cutting Path

When designing the cutting path, it is necessary to consider the properties of titanium alloy to avoid problems such as cutting too deep or too shallow. Generally, progressive cutting and equal division cutting technologies should be adopted to reduce thermal deformation of titanium alloy and stress concentration during cutting.

Accuracy Requirements

The machining accuracy of titanium alloy special-shaped parts is relatively high, generally requiring about ±0.005mm. During machining, it is necessary to control the cutting depth and feed speed, as well as the wear of the tool.

In summary, titanium alloy machining is a high-tech machining process that requires professional knowledge and experience. During OEM precision CNC machining, attention needs to be paid to key points such as cooling fluid, tools, and programming parameters, and parameters that need to be adjusted flexibly according to specific conditions to obtain the best machining effect and precision.

Surface Finishing Process What Are the Different Products Suitable For What Process?October 24, 2023The whole process of processing, in the selection of the appropriate processing method CNC processing or 3D printing, after the completion of processing, most of them need surface treatment. Meet the corrosion resistance, abrasion resistance, decoration or other special functional requirements of the product.view

Surface Finishing Process What Are the Different Products Suitable For What Process?October 24, 2023The whole process of processing, in the selection of the appropriate processing method CNC processing or 3D printing, after the completion of processing, most of them need surface treatment. Meet the corrosion resistance, abrasion resistance, decoration or other special functional requirements of the product.view 4140 vs 4130 Steel: A Comparison of Two Common Alloy SteelsNovember 27, 2023Steel is one of the most widely used materials in various industries, such as construction, automotive, aerospace, and manufacturing. Steel has many types and grades, each with different chemical compositions and mechanical properties.view

4140 vs 4130 Steel: A Comparison of Two Common Alloy SteelsNovember 27, 2023Steel is one of the most widely used materials in various industries, such as construction, automotive, aerospace, and manufacturing. Steel has many types and grades, each with different chemical compositions and mechanical properties.view Galvanneal vs Galvanized: Which Sheet Metal Material Is Right for Your Manufacturing Needs?March 22, 2024Galvannealed and galvanized steel are distinct types of sheet metal, produced through different processes and possessing unique properties. Read on to find out more!view

Galvanneal vs Galvanized: Which Sheet Metal Material Is Right for Your Manufacturing Needs?March 22, 2024Galvannealed and galvanized steel are distinct types of sheet metal, produced through different processes and possessing unique properties. Read on to find out more!view How to DIY CNC Machine?November 2, 2023Are you ready to unlock the world of CNC machining from the comfort of your own workshop? In this article, I will guide you through the process of creating your very own DIY CNC machine, step by step. Whether you're a seasoned DIY enthusiast or just starting out, this article will equip you with the knowledge and skills you need to build, operate, and maintain your CNC machine.view

How to DIY CNC Machine?November 2, 2023Are you ready to unlock the world of CNC machining from the comfort of your own workshop? In this article, I will guide you through the process of creating your very own DIY CNC machine, step by step. Whether you're a seasoned DIY enthusiast or just starting out, this article will equip you with the knowledge and skills you need to build, operate, and maintain your CNC machine.view Top 6 Types of Rivets and Their Common UsesAugust 11, 2023Rivets hold a unique position in the history of engineering and construction. These seemingly small fasteners have played a critical role in joining materials together. Based on their properties and d...view

Top 6 Types of Rivets and Their Common UsesAugust 11, 2023Rivets hold a unique position in the history of engineering and construction. These seemingly small fasteners have played a critical role in joining materials together. Based on their properties and d...view Challenge the Production of Mirror Discharge Mold Parts with H2 Grade Machining AccuracyMarch 2, 2023Challenge time: February 2023Challenge location: Longhua, Shenzhen, ChinaCustomer information: Singaporean high-quality mold vendorsNo nonsense, first upload the customer photo:Customer physical photo...view

Challenge the Production of Mirror Discharge Mold Parts with H2 Grade Machining AccuracyMarch 2, 2023Challenge time: February 2023Challenge location: Longhua, Shenzhen, ChinaCustomer information: Singaporean high-quality mold vendorsNo nonsense, first upload the customer photo:Customer physical photo...view

EN

EN

ru

ru