Steel is one of the most widely used materials in various industries, such as construction, automotive, aerospace, and manufacturing. However, steel is also susceptible to corrosion and rust when exposed to moisture and oxygen. Therefore, steel often needs a protective coating or a heat treatment to enhance its durability and performance. Two common types of steel are 1018 and 4140, which both belong to the category of carbon steel. However, these two types of steel have different characteristics and applications, which may affect your choice of steel for your project. In this article, we will compare 1018 and 4140 steel in terms of their production process, composition, properties, and uses.

1018 and 4140 steel are both produced by a cold drawing process, which involves pulling the steel through a die or a series of dies to reduce its diameter and increase its strength. However, the difference lies in the final step of the process. 1018 steel is left in the cold drawn state, while 4140 steel undergoes a heat treatment to achieve the desired mechanical properties. The heat treatment of 4140 steel consists of three stages: annealing, quenching, and tempering. Annealing is the process of heating the steel to a high temperature and then cooling it slowly, which softens the steel and makes it more ductile and workable. Quenching is the process of cooling the steel rapidly in water or oil, which hardens the steel and increases its strength and wear resistance. Tempering is the process of reheating the steel to a lower temperature and then cooling it slowly, which reduces the brittleness and improves the toughness and ductility of the steel. This additional heat treatment step changes the structure and composition of the steel, resulting in different properties and appearance of the steel.

1018 and 4140 steel have different chemical compositions that affect their performance and suitability for various applications. The main difference is the carbon content, which determines the hardness and hardenability of the steel. 1018 steel has a low carbon content of 0.18%, while 4140 steel has a medium carbon content of 0.40%. This means that 1018 steel is softer and more easily machined than 4140 steel, but also less hardenable and less resistant to wear. 4140 steel, on the other hand, is harder and more difficult to machine than 1018 steel, but also more hardenable and more resistant to wear. In addition, 4140 steel contains small amounts of chromium and molybdenum, which are alloying elements that improve the strength, toughness, and corrosion resistance of the steel. 1018 steel, on the other hand, does not contain any alloying elements, making it a plain carbon steel. The table below summarizes the chemical compositions of both types of steel.

| Element | 1018 Steel | 4140 Steel |

|---|---|---|

| Iron | 98.81-99.26% | 96.79-97.78% |

| Carbon | 0.18% | 0.40% |

| Manganese | 0.60-0.90% | 0.75-1.00% |

| Phosphorus (max) | 0.04% | 0.035% |

| Sulfur (max) | 0.05% | 0.040% |

| Chromium | - | 0.80-1.10% |

| Molybdenum | - | 0.15-0.25% |

1018 and 4140 steel have different physical and mechanical properties that affect their performance and suitability for various applications. Some of the main properties are:

• Hardness: Hardness is the measure of the resistance of a material to indentation or abrasion. Hardness is usually expressed in terms of the Rockwell or Brinell scales, which use different methods and units to measure the hardness of a material. 4140 steel has a higher hardness than 1018 steel, as the higher carbon content and the alloying elements make it harder and more resistant to wear. The typical hardness values of 4140 steel in the annealed state are 197 Brinell or 13 Rockwell C, while the typical hardness values of 1018 steel in the cold drawn state are 126 Brinell or 71 Rockwell B.

• Strength: Strength is the measure of the ability of a material to withstand an applied force without breaking or deforming. Strength is usually expressed in terms of the ultimate tensile strength, which is the maximum stress that a material can withstand before failure, or the yield strength, which is the stress that causes a material to deform permanently. 4140 steel has a higher strength than 1018 steel, as the higher carbon content and the heat treatment make it stronger and more resistant to deformation. The typical ultimate tensile strength and yield strength of 4140 steel in the annealed state are 655 MPa and 415 MPa, respectively, while the typical ultimate tensile strength and yield strength of 1018 steel in the cold drawn state are 440 MPa and 370 MPa, respectively.

• Toughness: Toughness is the measure of the ability of a material to absorb energy and resist fracture. Toughness is usually expressed in terms of the impact strength, which is the amount of energy that a material can absorb before breaking under an impact load, or the fracture toughness, which is the resistance of a material to crack propagation. 4140 steel has a higher toughness than 1018 steel, as the alloying elements and the heat treatment make it more ductile and more resistant to fracture. The typical impact strength of 4140 steel in the annealed state is 54 J, while the typical impact strength of 1018 steel in the cold drawn state is 27 J. The typical fracture toughness of 4140 steel in the annealed state is 50 MPa√m, while the typical fracture toughness of 1018 steel in the cold drawn state is 25 MPa√m.

• Machinability: Machinability is the measure of the ease of cutting, shaping, and drilling a material using a machine tool. Machinability is usually expressed in terms of the cutting speed, which is the rate at which a material can be machined without excessive tool wear or surface damage, or the machinability rating, which is a relative index that compares the machinability of a material to a standard material. 1018 steel has a higher machinability than 4140 steel, as the lower carbon content and the simpler composition make it easier to machine without excessive tool wear or surface damage. The typical cutting speed of 1018 steel in the cold drawn state is 76 m/min, while the typical cutting speed of 4140 steel in the annealed state is 66 m/min. The machinability rating of 1018 steel in the cold drawn state is 70%, while the machinability rating of 4140 steel in the annealed state is 66%.

• Weldability: Weldability is the measure of the ability of a material to be joined by welding without compromising the quality and strength of the weld. Weldability is usually affected by factors such as the carbon content, the alloying elements, the heat treatment, and the preheating and post-welding treatments of the material. 1018 steel has a higher weldability than 4140 steel, as the lower carbon content and the absence of alloying elements make it easier to weld without the risk of cracking, embrittlement, or distortion. 1018 steel can be welded by various methods, such as gas metal arc welding, gas tungsten arc welding, shielded metal arc welding, and resistance welding, without the need for preheating or post-welding treatments. 4140 steel, on the other hand, requires careful attention to the welding parameters, such as the preheating temperature, the interpass temperature, the cooling rate, and the post-welding treatments, to avoid cracking, embrittlement, or distortion. 4140 steel can be welded by gas metal arc welding, gas tungsten arc welding, and shielded metal arc welding, but it requires preheating to 150-260°C, maintaining the interpass temperature below 315°C, and tempering the weld at 540-650°C.

1018 and 4140 steel have different uses depending on their properties and appearance. Some of the typical uses of both types of steel are:

• 1018 steel: 1018 steel is widely used for low-stress applications that require good machinability and weldability, such as bolts, screws, shafts, gears, and general-purpose parts. 1018 steel is also suitable for cold forming processes, such as swaging, crimping, and bending, where the steel can be shaped and bent without the need for extensive heating. 1018 steel is also cost-effective, making it a popular option for

low-cost and high-volume production.

• 4140 steel: 4140 steel is widely used for high-stress applications that require high strength, toughness, and wear resistance, such as axles, gears, shafts, pistons, and crankshafts. 4140 steel is also suitable for heat treatment processes, such as hardening, tempering, and annealing, where the steel can be modified to achieve the desired mechanical properties. 4140 steel is also versatile, making it a popular option for various industries, such as automotive, aerospace, oil and gas, and defense.

1018 and 4140 steel are both types of carbon steel that are produced by a cold drawing process. However, they have different production processes, compositions, properties, and uses, which may affect your choice of steel for your project. 1018 steel has a low carbon content of 0.18%, while 4140 steel has a medium carbon content of 0.40%. This means that 1018 steel is softer and more easily machined than 4140 steel, but also less hardenable and less resistant to wear. 4140 steel, on the other hand, is harder and more difficult to machine than 1018 steel, but also more hardenable and more resistant to wear. In addition, 4140 steel contains small amounts of chromium and molybdenum, which are alloying elements that improve the strength, toughness, and corrosion resistance of the steel. 1018 steel, on the other hand, does not contain any alloying elements, making it a plain carbon steel. 1018 steel is widely used for low-stress applications that require good machinability and weldability, while 4140 steel is widely used for high-stress applications that require high strength, toughness, and wear resistance.

If you are looking for a reliable and professional service for your steel fabrication needs, I recommend you to check out Richconn's CNC machining service. Richconn is a leading machining manufacturer that offers high-quality and cost-effective CNC machining solutions for various materials, including steel, aluminum, brass, copper, and plastic. Richconn has a team of experienced and skilled engineers and technicians who can handle any design and specification you may have. Richconn also has a fast turnaround time and a strict quality control system that ensures your satisfaction and success. To learn more about Richconn's CNC machining service, please visit their website or contact them today.

Different Types of Bearings: Their Distinctive Features and Diverse UsesMay 28, 2024Learn about the importance of mechanical bearings, different types, and how to choose the right one for your needs. Explore applications in various fields and factors to consider for smooth and precise motions.view

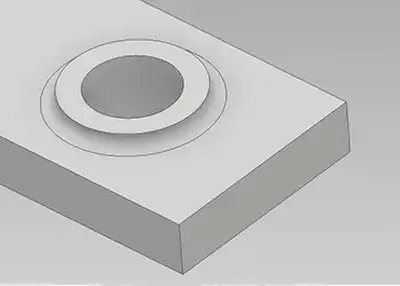

Different Types of Bearings: Their Distinctive Features and Diverse UsesMay 28, 2024Learn about the importance of mechanical bearings, different types, and how to choose the right one for your needs. Explore applications in various fields and factors to consider for smooth and precise motions.view What is a Machined Boss: A Comprehensive GuideNovember 8, 2023In the world of precision engineering, the term machined boss may not be a household name, but it is undoubtedly a crucial element that underpins countless industries. Whether you're a novice looking to expand your knowledge or a seasoned professional seeking in-depth insights, this article will serve as your comprehensive guide to understanding what a machined boss is, how it works, and why it matters.view

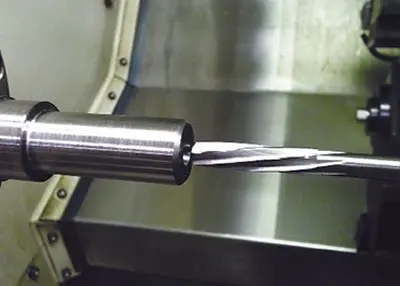

What is a Machined Boss: A Comprehensive GuideNovember 8, 2023In the world of precision engineering, the term machined boss may not be a household name, but it is undoubtedly a crucial element that underpins countless industries. Whether you're a novice looking to expand your knowledge or a seasoned professional seeking in-depth insights, this article will serve as your comprehensive guide to understanding what a machined boss is, how it works, and why it matters.view Turning Cylindrical PartsOctober 16, 2023In the past, everything was simple: round parts were turned on lathes, while non-round parts were machined on mills. With the advent of CNC machining centers that effortlessly insert round part features, the dividing line between the two machining processes became blurred.view

Turning Cylindrical PartsOctober 16, 2023In the past, everything was simple: round parts were turned on lathes, while non-round parts were machined on mills. With the advent of CNC machining centers that effortlessly insert round part features, the dividing line between the two machining processes became blurred.view How to remove chrome plating from sheet metal?November 24, 2023Chrome plating is a common metal finish that improves the wear resistance, corrosion resistance, aesthetics and hardness of the metal.view

How to remove chrome plating from sheet metal?November 24, 2023Chrome plating is a common metal finish that improves the wear resistance, corrosion resistance, aesthetics and hardness of the metal.view What Are Machined Rotors?November 8, 2023Welcome to the world of precision engineering, where the subtle details can make a world of difference. In the realm of CNC machining and automotive components, 'Machined Rotors' emerge as a pivotal player, quietly ensuring your safety and vehicle performance.view

What Are Machined Rotors?November 8, 2023Welcome to the world of precision engineering, where the subtle details can make a world of difference. In the realm of CNC machining and automotive components, 'Machined Rotors' emerge as a pivotal player, quietly ensuring your safety and vehicle performance.view Extrusion Blow Molding: A Guide to the Process, Materials, and ApplicationsDecember 5, 2023Extrusion blow molding is a process of forming hollow plastic parts by extruding a molten tube of polymer and inflating it with air inside a mold. It is one of the most common and versatile methods of producing plastic containers, such as bottles, jars, jugs, and drums.view

Extrusion Blow Molding: A Guide to the Process, Materials, and ApplicationsDecember 5, 2023Extrusion blow molding is a process of forming hollow plastic parts by extruding a molten tube of polymer and inflating it with air inside a mold. It is one of the most common and versatile methods of producing plastic containers, such as bottles, jars, jugs, and drums.view

EN

EN

ru

ru