Iron is a highly versatile and widely used metal with various types and forms. Several different types of iron are utilized to create diverse products and materials, like wrought iron entry doors, iron gates, and iron railings, among others. The properties of different types of ironing can be altered by how blacksmiths work with the raw iron, enabling the production of various types of iron. Let’s dive into their introduction, properties and uses.

Pure iron comes from an electric arc furnace with high temperatures to melt the iron. Called "butter iron", it is nearly 99.8% pure with a small amount of carbon and manganese. Trace elements exist, some adding properties. It is widely used in producing special alloy steels and in various industries. Also, it's used in making magnets, gaskets, etc. Pure iron is too soft and reactive for real use, so the "iron" we use for daily purposes is actually iron alloy mixed with carbon to make stronger forms like steel. There are different types of irons and steel with varying amounts of alloying elements.

The basic raw iron is referred to as pig iron since it is produced in the form of chunky molded blocks that are known as pigs. Pig iron is produced by heating an iron ore within a blast furnace, which is an enormous industrial fireplace shaped like a cylinder, and into which huge drafts of hot air are introduced in regular "blasts". The iron produced in a blast furnace is an alloy that contains approximately 90–95 percent iron, 3–4 percent carbon, and traces of other elements like silicon, manganese, and phosphorus, depending on the ore utilized. Pig iron is considerably harder than 100 percent pure iron, yet it is still too weak for most everyday applications.

Wrought iron is one of the first iron metals created by blacksmiths, which is made by heating iron in a furnace till reaching the desired temperature. Then, the blacksmith hammers and shapes the iron into different shapes based on the produced product. It represents a pure form of iron metals with extremely low carbon content and its characteristic lies in the fibrous and grainy look. Wrought iron is well-known for its strength, malleability, and corrosion resistance, and was historically used for decorative purposes like gates, railings, and ornamental work.

Wrought iron can be reheated as required, allowing it to be bent, shaped, and hammered further. Unlike other types of iron, it is mostly pure iron with very little carbon and other materials. Consequently, wrought iron is highly durable, making it perfect for wrought iron doors, gates, and railings. Moreover, before the invention of steel, it was a popular building material for support beams. Nowadays, Wrought iron is mainly applied to doors, gates, railings, and for decorative purposes.

Cast iron is a type of iron which has a higher carbon content in comparison with wrought iron. It is brittle and has a coarse-grained structure. Cast iron is recognized for its superb heat retention and even heat distribution features, making it appropriate for applications such as cookware, engine blocks, pipes, and construction materials.

There are different types of cast iron. Presently, the common classification scheme divides cast irons into four basic types: white cast iron, gray cast iron, ductile cast iron, and malleable cast iron. White cast iron results from metastable solidification and has a characteristic white crystalline fracture surface. Gray cast iron shows a gray fracture surface with ferrite and dispersed graphite flakes, appearing gray due to the exposed graphite. Ductile cast iron is called so because it exhibits measurable ductility in the as-cast form, also known as nodular or spheroidal graphite cast iron, while neither white nor gray iron shows significant ductility in a standard tensile test. Malleable cast iron is cast as white cast iron and then 'malleabilized'. Its micro structure consists of ferrite and particles of free graphite, including a form of graphite called temper carbon.

Stainless steel is an iron alloy that combines with chromium as well as other elements like nickel and molybdenum. It presents a high resistance to corrosion, which makes it applicable in areas where durability and corrosion resistance are crucial, such as kitchen utensils, appliances, surgical instruments, and architectural structures.

Carbon steel is an alloy composed of iron along with a small quantity of carbon. It is one of the common types of ironing and is more potent and harder compared to iron as a result of the elevated carbon content. Carbon steel is extensively employed in numerous industries, encompassing construction, automotive, and machinery. It can be further categorized into diverse iron types in accordance with the carbon content, like low carbon steel, medium carbon steel, and high carbon steel.

Alloy steels are made up of types of iron metals and carbon as well as one or more other elements, such as chromium, copper, manganese, nickel, silicon, or vanadium. The additional elements in alloy steels give them some important advantages and improved properties compared to ordinary carbon steels. Alloy steels are generally stronger, harder, tougher, and more durable than carbon steels.

Tool steels are exceptionally hard alloy steels that are employed to create tools, dies, and machine components. They are composed of iron and carbon along with added elements like nickel, molybdenum, or tungsten to impart additional hardness and resistance to wear. Moreover, tool steels are also strengthened through a process known as tempering, wherein the steel is initially heated to a high temperature, subsequently cooled extremely rapidly, and then reheated to a lower temperature.

H2: Conclusion

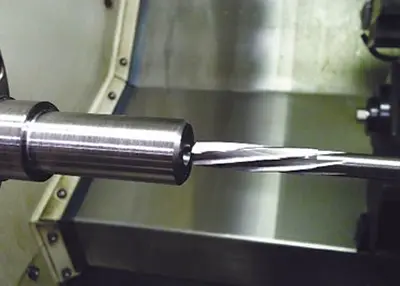

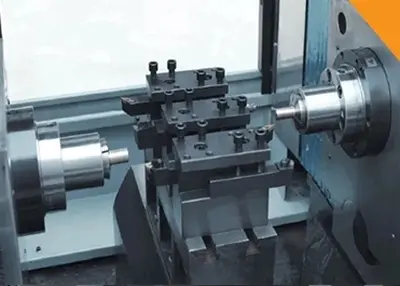

Different types of iron are widely used in CNC. Selecting the proper cast iron for your application demands an understanding of all the potential benefits each type can provide.

By collaborating with the seasoned team of Richconn, you can be sure that the right material will be selected for your CNC machining project. Regarding the CNC machining of cast iron parts, Richconn Works is unrivaled. With many years of presence in the industry, they have refined their process through extensive experience and cumulative expertise. The team of machinists at Richconn is one of the most knowledgeable and understands the best ways to turn intricate designs into reality and to help customers optimize their finished products. Coupled with ultra-modern equipment, you can obtain unbeatable accuracy and outstanding quality - guaranteed.

How to Reduce the Cost of CNC Machined Parts Through Structural DesignOctober 20, 2023CNC machined parts, i.e. parts processed by CNC equipment, CNC machining, usually refers to the precision machining method digitally controlled by a computer, which has become a common method of machining in nowadays.view

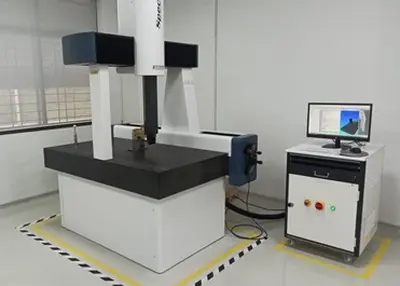

How to Reduce the Cost of CNC Machined Parts Through Structural DesignOctober 20, 2023CNC machined parts, i.e. parts processed by CNC equipment, CNC machining, usually refers to the precision machining method digitally controlled by a computer, which has become a common method of machining in nowadays.view What Is a CMM Machine: Components, Uses, and BenefitsMarch 15, 2024Here is a thorough introduction to CMM machines from components, uses to benefits. Let’s have a deeper look and choose the best CMM service for your projects.view

What Is a CMM Machine: Components, Uses, and BenefitsMarch 15, 2024Here is a thorough introduction to CMM machines from components, uses to benefits. Let’s have a deeper look and choose the best CMM service for your projects.view CNC Cutting Aluminum Sheets for Electronics EnclosuresFebruary 29, 2024Elevating Electronics Enclosures with CNC PrecisionIn today's fast-paced technological landscape, where precision and efficiency are critical, the manufacturing of electronics enclosures demands i...view

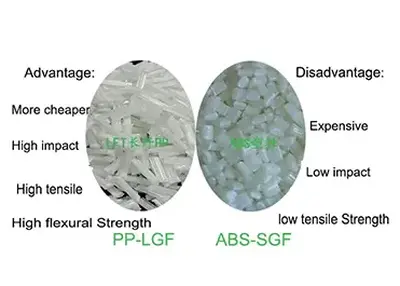

CNC Cutting Aluminum Sheets for Electronics EnclosuresFebruary 29, 2024Elevating Electronics Enclosures with CNC PrecisionIn today's fast-paced technological landscape, where precision and efficiency are critical, the manufacturing of electronics enclosures demands i...view ABS vs. Polypropylene (PP): A Comparison of Two Common PlasticsNovember 28, 2023Plastics are widely used materials in various industries, such as packaging, automotive, medical, and consumer products. Plastics are synthetic or semi-synthetic polymers that can be molded or shaped into different forms and products. There are many types and grades of plastics, each with different chemical compositions and physical properties.view

ABS vs. Polypropylene (PP): A Comparison of Two Common PlasticsNovember 28, 2023Plastics are widely used materials in various industries, such as packaging, automotive, medical, and consumer products. Plastics are synthetic or semi-synthetic polymers that can be molded or shaped into different forms and products. There are many types and grades of plastics, each with different chemical compositions and physical properties.view Demystifying CNC Lathe Machining – Unveiling the Precision PowerhouseNovember 3, 2023In the heart of precision manufacturing, CNC (Computer Numerical Control) lathe machining stands as a true marvel. It's a technology that has transformed the way we create parts and components across various industries.view

Demystifying CNC Lathe Machining – Unveiling the Precision PowerhouseNovember 3, 2023In the heart of precision manufacturing, CNC (Computer Numerical Control) lathe machining stands as a true marvel. It's a technology that has transformed the way we create parts and components across various industries.view The Importance of Using CNC Processing for Medical Precision PartsDecember 30, 2022Medical device components are impacted by rising health costs and technological advancements brought about by the growing aging population. Medical equipment helps to improve the progress of basic med...view

The Importance of Using CNC Processing for Medical Precision PartsDecember 30, 2022Medical device components are impacted by rising health costs and technological advancements brought about by the growing aging population. Medical equipment helps to improve the progress of basic med...view

EN

EN

ru

ru