Anodizing, the process of forming an oxide film on aluminum products (anode) under the action of an applied current under the corresponding electrolyte and specific process conditions of metal or alloy electrochemical alumina and its alloys. Anodizing usually refers to sulfuric acid anodizing unless otherwise specified. In order to overcome the defects of surface hardness and wear resistance of aluminum alloy, expand the scope of application and prolong the service life, surface treatment technology has become an indispensable part of the use of aluminum alloy, and anodizing technology is the most widely used and most successful.

The so-called anodization of aluminum is an electrolytic oxidation process, in which the surface of aluminum and aluminum alloys is usually transformed into an oxide film, which has protective, decorative and some other functional properties. The anodization of aluminum from this definition only includes the part of the process of forming an anodized film.

A metal or alloy product is used as an anode, and an oxide film is formed on the surface by electrolysis. Metal oxide films change the surface state and properties, such as surface coloration, improve corrosion resistance, enhance wear resistance and hardness, and protect metal surfaces. For example, aluminum anodization, aluminum and its alloys are placed in a corresponding electrolyte (such as sulfuric acid, chromic acid, oxalic acid, etc.) as an anode, and electrolysis is carried out under specific conditions and the action of an applied current. The aluminum of the anode or its alloy is oxidized, and a thin layer of aluminum oxide is formed on the surface, the thickness of which is 5-30 microns, and the hard anodic oxide film can reach 25-150 microns. Anodized aluminum or its alloy improves its hardness and wear resistance, up to 250-500 kg/mm2, good heat resistance, hard anodized film melting point up to 2320K, excellent insulation, shock resistance The breakdown voltage is as high as 2000V, which enhances the corrosion resistance and does not corrode for thousands of hours in ω=0.03NaCl salt spray. There are a lot of micropores in the thin oxide film layer, which can adsorb various lubricants. CNC anodized aluminum is suitable for the manufacture of engine cylinders or other wear-resistant parts; the film micropores have strong adsorption capacity and can be colored into various beautiful and bright colors. Non-ferrous metals or their alloys (such as aluminum, magnesium and their alloys) can be anodized. This method is widely used in mechanical parts, aircraft and auto parts, precision instruments and radio equipment, daily necessities and architectural decoration.

Generally speaking, the anode is made of aluminum or aluminum alloy as the anode, and the cathode is selected from the lead plate, and the aluminum and lead plate are placed in an aqueous solution, which contains sulfuric acid, oxalic acid, chromic acid, etc. An oxide film is formed on the surface. Of these acids, the most widespread is anodizing with sulfuric acid.

Choosing a Heat Resistant PlasticOctober 17, 2023If you've ever left a food container in the microwave for too long, you know that some plastics don't tolerate high temperatures very well. Depending on the type of container, you might be storing the food from the night before in polypropylene (PP), polycarbonate (PC) or polyethylene (PE), none of which excel at heat resistance.view

Choosing a Heat Resistant PlasticOctober 17, 2023If you've ever left a food container in the microwave for too long, you know that some plastics don't tolerate high temperatures very well. Depending on the type of container, you might be storing the food from the night before in polypropylene (PP), polycarbonate (PC) or polyethylene (PE), none of which excel at heat resistance.view Luxury carbon fiber: NTPTTM ultra-high performance prepreg carbon fiber full resolutionSeptember 25, 2023With the improvement of people's living standards, the luxury market is booming. Many luxury goods use specialized high-tech materials in their design and manufacturing processes to ensure that th...view

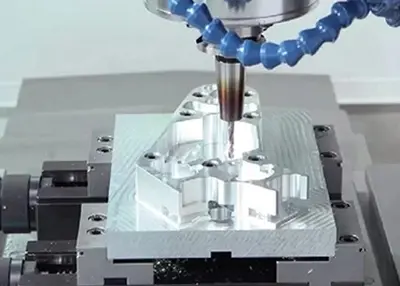

Luxury carbon fiber: NTPTTM ultra-high performance prepreg carbon fiber full resolutionSeptember 25, 2023With the improvement of people's living standards, the luxury market is booming. Many luxury goods use specialized high-tech materials in their design and manufacturing processes to ensure that th...view Understanding machining tools: types, uses and selectionNovember 1, 2023Machining tools are vital tools in manufacturing, used to cut, chip, grind and shape a wide range of materials, from metals to plastics to wood. Different tool types are used for different processes and materials to meet a variety of machining needs. Below are five common types of machining tools that are used in a wide range of manufacturing and processing applications.view

Understanding machining tools: types, uses and selectionNovember 1, 2023Machining tools are vital tools in manufacturing, used to cut, chip, grind and shape a wide range of materials, from metals to plastics to wood. Different tool types are used for different processes and materials to meet a variety of machining needs. Below are five common types of machining tools that are used in a wide range of manufacturing and processing applications.view CNC Water Jet Cutter: Precision in Cutting TechnologySeptember 28, 2023Have you ever dreamed of achieving flawless precision in cutting materials, from metal to delicate fabrics, with utmost efficiency and accuracy? Your dream can become a reality with the marvel of technology known as the CNC Water Jet Cutter.view

CNC Water Jet Cutter: Precision in Cutting TechnologySeptember 28, 2023Have you ever dreamed of achieving flawless precision in cutting materials, from metal to delicate fabrics, with utmost efficiency and accuracy? Your dream can become a reality with the marvel of technology known as the CNC Water Jet Cutter.view Five Axis CNC Machining Features and AdvantagesNovember 4, 2022Five-axis machining machines to quickly and efficiently manufacture complex milled parts in small batches from a variety of materials. Using five-axis precision machining is often a more efficient way...view

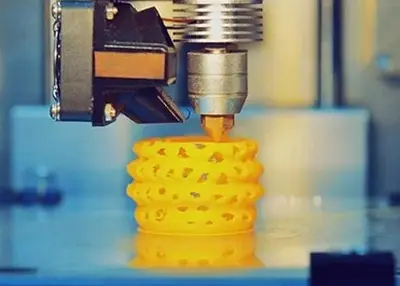

Five Axis CNC Machining Features and AdvantagesNovember 4, 2022Five-axis machining machines to quickly and efficiently manufacture complex milled parts in small batches from a variety of materials. Using five-axis precision machining is often a more efficient way...view What Is Prototype Manufacturing? Process, Benefits, and Vital TipsOctober 25, 2023A good understanding of prototype manufacturing will help you make the best choice for your project. Learn more about it from this passage.view

What Is Prototype Manufacturing? Process, Benefits, and Vital TipsOctober 25, 2023A good understanding of prototype manufacturing will help you make the best choice for your project. Learn more about it from this passage.view

EN

EN

ru

ru