The functionality of a part is largely dependent on obvious factors such as shape, size, wall thickness, joints, etc. Less obvious, but equally important, are the properties of the material from which it is injection molded, CNC machined, or 3D printed (cut, bent, formed, etc.).

Design occurs at the macro level, while material properties are usually decided at the molecular level. The earlier in the design process you start thinking about materials and their properties, the more effective and economical your finished design will be. This design tip is designed to help you with that early evaluation. It provides an overview of the four general categories of material properties (metals and plastics), some important considerations when selecting materials for your next part design, and design issues that are often overlooked.

Selecting the right material - be it metal or plastic - is often simple and done almost casually. However, it can also be complex and critical to the performance of a part. Let's say you want to make a case for a piece of equipment designed for indoor use. A majority of plastic cases are not particularly demanding from a thermal or electrical standpoint, do not have extreme mechanical properties, and can therefore be used in relatively undemanding environments. Most of these parts can be made of ABS, polycarbonate (PC) or an ABS/PC blend.

On the other hand, imagine the housing for a motorcycle air filter. This must be opened and closed periodically for filter replacement. This function can be performed by an active hinge joint or an integrated spring clip. The housing must withstand attack from flying debris, engine heat, UV radiation from the sun, moisture from various sources, and chemical exposure to fuel and cleaning chemicals. Determining the right material for this application usually requires research and iterative prototyping.

A motorcycle's air filter is a good example of a component that must balance multiple material properties, such as heat resistance, strength and flexibility

A smartphone's components may pose an even greater challenge. Their functions may include heat dissipation and protection, electrical insulation, selective pass-through and blocking of radio signals; in the case of cases, protection against repeated dropping is added. Each component of this complicated design has very specific requirements, which in turn require specific material properties. Thus, the right material selection is critical.

Effective material selection begins with a clear understanding of the functions of the complete device or assembly. Next, the functions of the individual part in the overall operation must be determined. If there are multiple aspects to consider, prioritize and separate indispensable from desirable but not necessary properties. For example, a smooth, cosmetic surface finishing that is essential in a handheld device may be more secondary if the strength of a fiberglass-reinforced material is needed to meet strength requirements. The list of possible considerations is long. However, they generally fall into one of these four categories: mechanical, physical, thermal and electrical material properties.

For those seeking high-quality CNC machining services, Shenzhen CNC machining offers advanced capabilities to meet diverse needs. When it comes to selecting materials, it's essential to consider both performance and cost. Richconn provides a range of cheap CNC materials that don't compromise on quality, as well as a comprehensive guide on CNC machining materials to help you make the best choice for your project.

Mechanical properties are the characteristics that a material exhibits when various forces are applied. These include characteristics such as tensile and compressive strength, flexibility and hardness.

In the case of plastics. Plastics have widely varying mechanical properties, ranging from flexible polypropylene for an active hinge joint to rigid glass-fiber-reinforced nylon.

For metals. In contrast, all metals are relatively rigid. For example, various types of steel are stiffer than aluminum

Physical properties are the cosmetic characteristics of a material and its response to chemicals and radiation. These include density and resistance to chemical corrosion and UV damage. It also includes cosmetic aspects, such as color and surface texture.

For plastics. The physical properties of plastics vary widely. For example, urethanes are a poor choice for humid environments, while plastics 3D-printed using stereolithography become brittle when exposed to UV light.

For metals. Metals also have varying tolerances to chemical exposure. Stainless steel is an obvious choice among metals for many potentially corrosive environments, but comes off poorly in other areas, such as heat transfer.

Thermal properties are responsible for how a material behaves at different temperatures. Does it deform easily in heat, or is it weakened by heat? Or does it become brittle in response to cold? Does it have good thermal conductivity or good insulating properties? Temperatures that affect the part can either be due to the environment or generated by the assembly in which the part performs its function.

For plastics. Thermal performance can play a large role in the selection of plastics. While silicone is ideal for fireproof tableware, many plastics can be damaged by just the heat in a closed car on a summer day.

For metals. Metals can generally withstand higher heat than most plastics. A nickel-chromium "superalloy," such as Inconel, can withstand temperatures up to 700°C, making it suitable for rocket drive components. In less demanding applications, aluminum may be the ideal material for a heat sink where stainless steel is not an option.

Electrical properties include characteristics such as conductivity, resistivity, and inductance.

For plastics. The electrical properties of plastics vary widely. This is particularly important to consider in compact devices, such as smartphones, in which current and signal must be isolated to avoid deformation, or in medical devices in which high currents or magnetic fields are used for diagnostic or treatment purposes.

For metals. Conductivity also varies widely among metals. Copper is usually our first choice when good conductivity is important. However, aluminum is also a good electrical conductor and, to boot, is inexpensive and particularly corrosion resistant when conductivity is not a critical factor.

Many designers have a few favorite materials that they always use unless they have obvious weaknesses. That's fine if the material meets the needs and the price is right. But in some cases, this means you're giving up advantages of another material that you might come across with a little research. It can also slow down your development process if you run into problems with a prototype that you could have anticipated ahead of time if you had researched the material properties. You may also find that you are already meeting requirements at a lower cost, which can pay off over a long production run. Here are a few examples:

* You may think that heat or UV damage to a product is irrelevant for indoor use. But what if it's left outside in the sun or in a closed car?

* Have you thought about all kinds of chemical exposure? Even if you warn against certain chemicals in the fine print, a resilient material can prevent users from being dissatisfied with your product.

* Have you considered all conditions of use? A car part may be protected from UV radiation under the hood but exposed to congested heat, while a similar part on a motorcycle will find the exact opposite conditions.

* How well will the part age? Is it disposable? Is it replaceable? Is it permanently installed?

* Does density matter? Some moving parts can benefit from light weight, while others need to be heavy to function properly.

* Size and strength can be interchangeable. A thinner part made of a sturdier material can save space. Material savings can offset higher unit costs.

* Surface quality is not just an aesthetic issue. Factors such as texture can be critical to ergonomics.

* The right material can help solve design problems. For example, an integrated spring clip or active hinge joints can eliminate the need for connectors.

* Heat can be a problem with many products. A well-designed heat sink made of the right metal or plastic can effectively dissipate heat from critical areas.

If you need additional assistance, please contact and by phone at +86-0755-28025755 or by email at sales@richconn.com.cn. To get your next design project rolling today, simply upload a 3D CAD model. You will receive an interactive quote within a few hours.

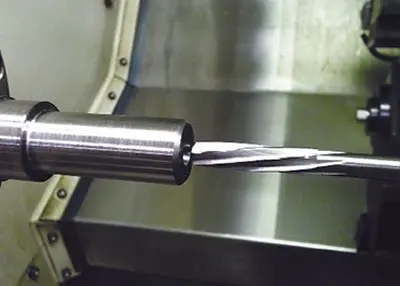

Turning Cylindrical PartsOctober 16, 2023In the past, everything was simple: round parts were turned on lathes, while non-round parts were machined on mills. With the advent of CNC machining centers that effortlessly insert round part features, the dividing line between the two machining processes became blurred.view

Turning Cylindrical PartsOctober 16, 2023In the past, everything was simple: round parts were turned on lathes, while non-round parts were machined on mills. With the advent of CNC machining centers that effortlessly insert round part features, the dividing line between the two machining processes became blurred.view Everything You Need to Know About CNC Machine ShopSeptember 13, 2023Are you looking to find a CNC machine shop in China? This article covers the information you need to know and helps you choose the best partner.view

Everything You Need to Know About CNC Machine ShopSeptember 13, 2023Are you looking to find a CNC machine shop in China? This article covers the information you need to know and helps you choose the best partner.view How to remove chrome plating from sheet metal?November 24, 2023Chrome plating is a common metal finish that improves the wear resistance, corrosion resistance, aesthetics and hardness of the metal.view

How to remove chrome plating from sheet metal?November 24, 2023Chrome plating is a common metal finish that improves the wear resistance, corrosion resistance, aesthetics and hardness of the metal.view An Ultimate Guide to Medical Device ManufacturingMarch 13, 2024Nowadays, manufacturing medical devices is becoming more and more important. This article will let you know more about medical device manufacturing.view

An Ultimate Guide to Medical Device ManufacturingMarch 13, 2024Nowadays, manufacturing medical devices is becoming more and more important. This article will let you know more about medical device manufacturing.view Unveiling the World of Helical Machined Springs: A Comprehensive ExplorationNovember 15, 2023Embarking on a journey through the intricate world of helical machined springs is more than just an exploration of engineering marvels – it's a pathway to unlocking innovation, efficiency, and reliability in diverse industries. In this article, I'll guide you through the essential aspects of helical machined springs, from their fundamental workings to practical applications and market trends.view

Unveiling the World of Helical Machined Springs: A Comprehensive ExplorationNovember 15, 2023Embarking on a journey through the intricate world of helical machined springs is more than just an exploration of engineering marvels – it's a pathway to unlocking innovation, efficiency, and reliability in diverse industries. In this article, I'll guide you through the essential aspects of helical machined springs, from their fundamental workings to practical applications and market trends.view Luxury carbon fiber: NTPTTM ultra-high performance prepreg carbon fiber full resolutionSeptember 25, 2023With the improvement of people's living standards, the luxury market is booming. Many luxury goods use specialized high-tech materials in their design and manufacturing processes to ensure that th...view

Luxury carbon fiber: NTPTTM ultra-high performance prepreg carbon fiber full resolutionSeptember 25, 2023With the improvement of people's living standards, the luxury market is booming. Many luxury goods use specialized high-tech materials in their design and manufacturing processes to ensure that th...view

EN

EN

ru

ru