Because of the increasing need for high-performance electronics, advanced devices with fast microprocessors and high transistor densities are being manufactured. This technical modification in such electronic components has resulted in increased heat load during operation. The proper heat sink ensures the best possible performance of electronics.

In this article, we will answer the question: What is a heat sink? what does a heat sink do? We would also explore the importance of a heat sink, the basics of a heat sink design, and how to choose the right heat sink for optimal electronics performance. Let’s get started.

We may ask what is heatsink. A heatsink is a device used to dissipate heat from electronic components, such as processors or graphics cards. It typically consists of a metal or aluminum structure with fins that increase the surface area for better heat dissipation. The heatsink absorbs the heat generated by the component and transfers it to the surrounding air, helping to keep the component cool and prevent overheating.

The proper heat sink ensures the best possible performance of electronics. There are six different types of heat sinks that can be used in an active or passive system. They are usually constructed of aluminum or copper. Some of the main types include:

Bonded Heat Sinks

These heat sinks are made by bonding fins to a base plate using thermal adhesive or epoxy. They can be made of either copper or aluminum or a combination of the two. They are cost-effective and suitable for low to medium-power applications.

Skived Heat Sinks

Skived heat sinks are made by cutting thin fins from a solid block of aluminum or copper. Skived heat sinks have a series of tightly packed fins on a base made of a single piece of metal, resulting in minimum thermal resistance. This manufacturing process allows for high fin density and efficient heat dissipation. Skived heat sinks are commonly used in high-power applications.

Stamped Heat Sinks

Stamped heat sinks are made by stamping or pressing fins into a base plate. The stamped metal fins are held together by one or more zipper fins that run perpendicular to the regular fins and interlock to maintain the distance. They are cost-effective and suitable for low to medium-power applications. However, they have lower fin density compared to skived heat sinks.

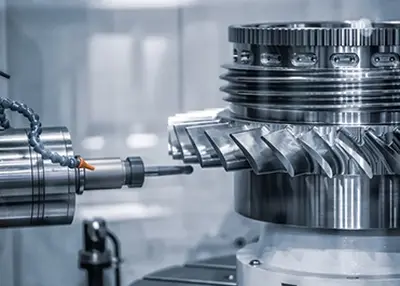

CNC Machined Heat Sinks

CNC-machined heat sinks are made by removing material from a solid block of aluminum or copper using computer-controlled milling machines. This allows for precise customization and complex designs. CNC-machined heat sinks are commonly used in high-performance applications where specific thermal requirements need to be met.

What does heat sink do? Actually, a heat sink is a device used to dissipate and disperse excess heat generated by electronic devices, such as computer processors or power transistors. When electronic devices are in operation, the electrical energy flowing through them is converted into heat energy due to resistive losses and other factors. If the heat produced is not efficiently dissipated, it can result in a temperature rise that exceeds the device's operating limits, leading to reduced performance, instability, or even permanent damage.

Analyzing the thermal performance of each electronic item is a difficult process. It is designed to absorb the heat and transfer it to the surrounding environment, thereby preventing the device from overheating and potentially malfunctioning or getting damaged.

1. Budget

Determine how much you are willing to spend on a heat sink. There are various options available at different price points, so it's important to find a balance between cost and performance.

2. Space Restrictions

We may consider a bigger high-heat sink. A larger heat sink means high thermal management. However, this is only true if the appropriate heat sink is chosen for the application. Heat sinks are frequently confined by the other components surrounding them, therefore a larger heat sink is not always possible. Furthermore, a more efficient heat sink design may have better thermal management than one that is simply larger.

3. Use of Thermal Paste

Thermal paste is required for heat sinks to effectively transfer heat from the component to the heat sink. The thermal resistance between the heat sink and the component increases if it is not used. This will have a negative impact on the heat sink's performance.

4. Features of Heat Sinks

Different heat sinks have various features like fins, heat pipes, or liquid cooling systems. Fins increase the surface area for better heat dissipation, heat pipes help transfer heat more efficiently, and liquid cooling systems can offer even better cooling performance. Consider the specific requirements of your device and choose a heat sink with the appropriate features.

5. Airflow Interaction

Proper airflow is crucial for effective heat dissipation. Consider how the heat sink's design interacts with the available airflow in the system. Ensure that there is sufficient space around and above the heat sink for adequate airflow and that the heat sink's fins or other design elements align with the direction of the airflow.

6. Heat from Surrounding Components

Some electronic components, such as memory modules or power transistors, may also generate heat that can affect the performance of the heat sink. Consider how the heat from surrounding components may impact the heat sink's effectiveness and choose a suitable heat sink that can handle the combined thermal load.

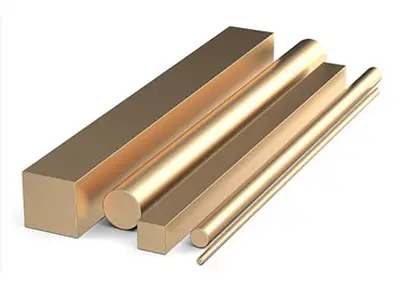

7. Material Composition

Heat sinks are commonly made of aluminum or copper due to their high thermal conductivity. Copper has better thermal conductivity but is more expensive, while aluminum is lightweight and cost-effective. Consider the requirements of your application and choose a material that best suits your needs.

Surface treatment has a significant impact on heat sink performance. The surface of the heat sink must be smooth and free of defects or roughness as these can limit heat transfer. A rough surface can create air pockets and limit the contact area between the heat sink and components, resulting in poor heat transfer and increased temperatures.

Richconn has extensive expertise in surface finishing and the most professional team, delivering the best performance at the most competitive pricing. During the heat sink design process, the following common surface finishing of heat sink that Richiconn can offer:

Heat sinks are of high importance and choosing the proper heat sinks is carefully structured to guarantee effective performance. Therefore, many things must be taken into consideration. This article talks about factors that can help you choose the right one. Do you want the best services of surface finishing on a heat sink at a low price? Contact our support team for surface finishing services on heat sink.

Rivets: 25 Types Of Introduction And User GuideSeptember 26, 2023Rivets are parts that join multiple components and structures together to form a complete body. These parts can be manipulated with some specialized tools. One of the panaceas of manufacturing is rivets. Depending on their design requirements and performance, different types of rivets can be used.view

Rivets: 25 Types Of Introduction And User GuideSeptember 26, 2023Rivets are parts that join multiple components and structures together to form a complete body. These parts can be manipulated with some specialized tools. One of the panaceas of manufacturing is rivets. Depending on their design requirements and performance, different types of rivets can be used.view Cast Aluminum vs Machined Aluminum: Unveiling the Crafting MarvelsNovember 13, 2023In the realm of metal fabrication, the choice between cast aluminum and machined aluminum holds the key to unlocking a world of possibilities. As a CNC machining service provider, we, at Richconn, understand the importance of making informed decisions in the manufacturing process. Let's embark on a journey to explore the nuances of these two techniques, dissecting their processes, comparing their performance, and uncovering their diverse applications.view

Cast Aluminum vs Machined Aluminum: Unveiling the Crafting MarvelsNovember 13, 2023In the realm of metal fabrication, the choice between cast aluminum and machined aluminum holds the key to unlocking a world of possibilities. As a CNC machining service provider, we, at Richconn, understand the importance of making informed decisions in the manufacturing process. Let's embark on a journey to explore the nuances of these two techniques, dissecting their processes, comparing their performance, and uncovering their diverse applications.view Four Requirements for Medical Component ProcessingMay 22, 2023For CNC machining of parts with multiple and complex surfaces, the sequence of CNC machining, heat treatment, and auxiliary processes should be arranged reasonably, and the connection between processe...view

Four Requirements for Medical Component ProcessingMay 22, 2023For CNC machining of parts with multiple and complex surfaces, the sequence of CNC machining, heat treatment, and auxiliary processes should be arranged reasonably, and the connection between processe...view Safety Issues in CNC Turning TechnologyApril 25, 2023Turning is a part of mechanical processing in lathe machining. Lathe machining mainly uses the turning tool to process the rotating workpiece. Lathes are mainly used to process shafts, discs, sleeves,...view

Safety Issues in CNC Turning TechnologyApril 25, 2023Turning is a part of mechanical processing in lathe machining. Lathe machining mainly uses the turning tool to process the rotating workpiece. Lathes are mainly used to process shafts, discs, sleeves,...view Titanium vs Steel: Is Titanium Stronger Than Steel?August 29, 2023Is titanium stronger than steel? Here's a brief guide that compares steel to titanium from different aspects.view

Titanium vs Steel: Is Titanium Stronger Than Steel?August 29, 2023Is titanium stronger than steel? Here's a brief guide that compares steel to titanium from different aspects.view Brass vs Bronze or Brass vs Copper: Which Is Better for Your Project?October 7, 2023This article introduces the difference between brass and bronze and copper, which can help you and your project find the right choice of these metals.view

Brass vs Bronze or Brass vs Copper: Which Is Better for Your Project?October 7, 2023This article introduces the difference between brass and bronze and copper, which can help you and your project find the right choice of these metals.view

EN

EN

ru

ru