Welcome to the world of Machined Bearings, where precision engineering meets mechanical efficiency. If you're here, you're probably as curious as I was when I first delved into this field. You're in for a treat because we've crafted a comprehensive guide to take you on a journey through Machined Bearings, from the basics to advanced applications.

Machined Bearings are fundamental components of mechanical systems, designed to facilitate the smooth, low-friction movement of rotating parts. They come in various shapes and sizes, each with a unique purpose. To better understand these essential components, let's take a closer look at some common types of Machined Bearings:

Ball Bearings: These are perhaps the most recognized type of Machined Bearings. They consist of small, spherical balls that distribute the load evenly and reduce friction. Ball bearings are used in a wide range of applications, from bicycles to industrial machinery.

Roller Bearings: Roller bearings, including cylindrical and tapered roller bearings, utilize cylindrical rolling elements instead of balls. They are known for their high load-carrying capacity and are often used in heavy-duty applications, such as conveyor systems.

Thrust Bearings: These bearings are engineered to support axial loads, making them ideal for applications like propeller shafts in ships and thrust reversers in aircraft.

Radial Bearings: Radial bearings are designed to handle perpendicular loads and are commonly used in applications where the load is primarily radial, like electric motors.

The working principles of Machined Bearings are based on reducing friction and enabling the smooth rotation of machinery. Here's a detailed breakdown of their functionality:

Friction Reduction: Machined Bearings are strategically placed between moving parts to minimize friction. This not only reduces wear and tear but also conserves energy and ensures the machinery operates more efficiently.

Load Distribution: Bearings distribute the load evenly across their contact surfaces, preventing localized stress concentrations. This even distribution of force ensures the longevity of both the bearing and the machinery.

Rotation Support: As machinery rotates, the bearings provide stable support, allowing components to move with minimal resistance. This is crucial in applications where precise movement is required.

Axial and Radial Support: Different types of bearings offer specific support for axial (along the axis of rotation) and radial (perpendicular to the axis of rotation) loads. This versatility allows for the efficient operation of various mechanical systems.

Lubrication: Proper lubrication is essential for Machined Bearings to function optimally. It reduces friction, dissipates heat, and prevents premature wear. Regular maintenance includes monitoring and replenishing lubricants as needed.

Understanding how Machined Bearings operate is vital in selecting the right type of bearing for a specific application and maintaining machinery for long-term reliability.

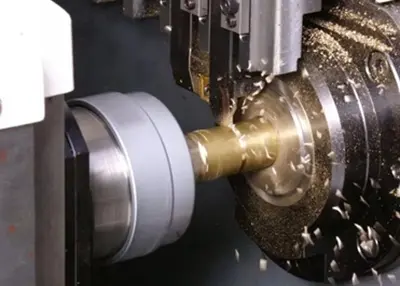

The quality and performance of Machined Bearings depend on precise manufacturing processes. Let's delve deeper into how these essential components are made:

Material Selection: Bearings are typically crafted from materials with excellent wear resistance and load-bearing capacity, such as chrome steel, stainless steel, or ceramic. The choice of material depends on the specific application's requirements.

Machining Processes: Bearing manufacturers employ advanced machining techniques to create the intricate shapes and surfaces required for smooth operation. This involves processes like turning, grinding, and superfinishing to achieve the desired tolerances and surface finishes.

Quality Control: Stringent quality control measures are taken at every step of the manufacturing process. Bearings are subject to various tests to ensure they meet industry standards. These tests include dimensional checks, noise level measurements, and dynamic load ratings.

Precision Assembly: Assembling Machined Bearings is a highly precise process. The inner and outer rings, rolling elements, and cages are meticulously fitted together to create a functional bearing unit.

Lubrication: Some bearings are pre-lubricated during the manufacturing process to ensure they are ready for use upon installation. Others may require on-site lubrication to suit the specific application.

By understanding the material selection, machining processes, quality control, and lubrication methods, you can appreciate the craftsmanship behind these small yet critical components that keep machinery running smoothly.

Machined Bearings find utility in an array of industries, each with its unique demands and requirements. Here's a closer look at their applications:

Automotive Industry: In the automotive world, Machined Bearings play a pivotal role in wheels, engines, transmissions, and suspension systems. They contribute to the smooth and efficient operation of vehicles, reducing friction and wear.

Aerospace and Aviation: The aerospace industry demands reliability and precision. Bearings are used in aircraft engines, landing gear, control systems, and more. They must withstand extreme conditions and maintain performance under high loads and speeds.

Industrial Machinery: From conveyor belts to manufacturing equipment, industrial machinery relies on bearings for uninterrupted operation. High load-carrying capacity and low friction are key factors in this sector.

Renewable Energy: Wind turbines and solar trackers harness renewable energy sources to generate electricity. Bearings support the rotational mechanisms, ensuring efficient energy production.

Medical Devices: In the medical field, precision is paramount. Bearings are used in surgical tools, imaging equipment, and even in prosthetic joints to provide smooth, accurate movement.

Heavy Equipment: Construction and mining equipment, as well as agricultural machinery, benefit from the rugged nature of Machined Bearings. They endure harsh conditions while ensuring mechanical efficiency.

Selecting the right type of bearing is essential to optimize performance in a given application. Let's dive deeper into the comparison of various Machined Bearings:

Ball Bearings vs. Roller Bearings: Ball bearings excel in applications requiring high speeds and low friction, whereas roller bearings offer superior load-carrying capacity, making them suitable for heavy-duty applications.

Thrust Bearings vs. Radial Bearings: Thrust bearings are engineered to support axial loads, while radial bearings are designed for perpendicular loads. Understanding the type of load your application experiences is crucial for the right choice.

Custom Bearings: In some cases, standard bearings may not meet the unique demands of a specific application. Custom bearings can be designed to exact specifications, ensuring an optimal fit and performance.

Factors to Consider: When selecting a bearing, factors like load type, speed, temperature, and lubrication requirements are paramount. We'll delve into the specifics of each factor to guide you in your decision-making process.

Part Three: Troubleshooting, Maintenance, and Richconn CNC Machining Services

While Machined Bearings are built to last, they may encounter issues over time. This section delves into common problems and their solutions:

Common Bearing Issues: We'll explore issues such as noise, vibration, overheating, and premature wear and provide guidance on how to diagnose and address these problems.

Proactive Maintenance: Regular maintenance is the key to extending bearing life. Learn about best practices for lubrication, cleaning, and inspections to keep your machinery in top shape.

Increasing Lifespan: Discover tips and tricks to maximize the lifespan of your bearings, ultimately reducing maintenance costs and downtime.

At Richconn CNC Machining Services, we pride ourselves on being a reliable supplier of Machined Bearings. This section offers insights into why you should consider us for your bearing needs:

Company Overview: Learn about our history, expertise, and commitment to quality. Our dedication to precision machining services ensures that you receive top-tier Machined Bearings.

Why Choose Richconn: We'll outline the advantages of working with us, including our responsive customer service, on-time delivery, and competitive pricing.

Custom Bearing Capabilities: If your application requires specialized bearings, we have the expertise and equipment to create custom solutions tailored to your unique requirements.

Success Stories: Explore real-world examples of how Richconn CNC Machining Services has delivered high-quality bearings and contributed to the success of our clients.

Quality Assurance: Quality is the cornerstone of our service. We'll detail our rigorous quality control procedures to ensure that every bearing we produce meets the highest standards.

State-of-the-Art Equipment: Richconn invests in cutting-edge machining technology, enabling us to manufacture bearings with exceptional precision and consistency.

Custom Solutions: For applications with unique demands, we offer custom bearing solutions. Learn about our design and engineering capabilities to address your specific requirements.

Timely Delivery: We understand the importance of prompt delivery to minimize downtime in your operations. Discover our commitment to on-time deliveries.

As we conclude this comprehensive guide to Machined Bearings, it's crucial to recap what we've covered:

You now have a firm understanding of what Machined Bearings are and how they work, including the various types available.

We've explored their applications across different industries, emphasizing their importance in keeping machinery running smoothly.

Choosing the right bearing for your specific application is critical, and we've delved into the factors to consider.

Maintenance and troubleshooting insights have been shared to help you ensure the longevity of your bearings.

Lastly, we've introduced Richconn CNC Machining Services as your trusted supplier, highlighting our capabilities and commitment to quality.

In the world of machinery, every component plays a crucial role, and Machined Bearings are no exception. By making informed decisions about these components, you can optimize the performance and longevity of your machinery.

To continue your journey into the world of Machined Bearings, you can take the following steps:

Identify Your Needs: Consider the specific requirements of your application, including load types, speeds, and environmental conditions.

Select the Right Bearing: With a better understanding of bearing types and factors to consider, choose the most suitable bearing for your machinery.

Implement Regular Maintenance: Follow best practices for lubrication, cleaning, and inspections to keep your bearings in top condition.

Consider Custom Solutions: If your application demands unique bearings, explore custom solutions with Richconn CNC Machining Services.

Contact Richconn: Reach out to us to discuss your bearing requirements and experience the quality and reliability that we offer.

By taking these steps, you can ensure the smooth operation of your machinery, minimize downtime, and optimize the performance of your equipment.

Thank you for accompanying us on this journey through the world of Machined Bearings. We hope this comprehensive guide has provided you with the knowledge and insights needed to make informed decisions in your field. If you have any further questions or require additional information, please don't hesitate to reach out to us. We look forward to assisting you in all your Machined Bearing needs.

What Is CNC Machining?April 4, 2023Definition of CNC MachiningCNC machining refers to the machining process conducted by a control system that controls the tools to perform various movements that meet the technical and processing requi...view

What Is CNC Machining?April 4, 2023Definition of CNC MachiningCNC machining refers to the machining process conducted by a control system that controls the tools to perform various movements that meet the technical and processing requi...view CNC Machining Surface FinishingOctober 23, 2023The surface finishing process is the final step in CNC machining. Different techniques eliminate surface irregularities, improve part appearance, and add strength and resistance for increased functionality. The finishing technique you use depends on specific requirements, such as industry standards, the application of the part, and the materials you are working with.view

CNC Machining Surface FinishingOctober 23, 2023The surface finishing process is the final step in CNC machining. Different techniques eliminate surface irregularities, improve part appearance, and add strength and resistance for increased functionality. The finishing technique you use depends on specific requirements, such as industry standards, the application of the part, and the materials you are working with.view Precision Engineered CNC Turning PartsSeptember 22, 2023CNC turned parts are a type of mechanical part that is manufactured through numerical control (Computer Numerical Control, CNC) technology.view

Precision Engineered CNC Turning PartsSeptember 22, 2023CNC turned parts are a type of mechanical part that is manufactured through numerical control (Computer Numerical Control, CNC) technology.view Carbon Steel: The Ultimate Guide - Types, Properties & PriceSeptember 8, 2023Carbon steel is one of the most common types of steel, as it is cheap, abundant, and versatile. Carbon steel found in countless products and structures, plays an indispensable role in various industri...view

Carbon Steel: The Ultimate Guide - Types, Properties & PriceSeptember 8, 2023Carbon steel is one of the most common types of steel, as it is cheap, abundant, and versatile. Carbon steel found in countless products and structures, plays an indispensable role in various industri...view Hot Rolled vs Cold Rolled: Which One Is Right for Your Project?February 26, 2024To optimize the properties of steel for specific applications, it is necessary to consider factors beyond its chemical composition. Hot rolling or cold rolling is a process employed to enhance the sha...view

Hot Rolled vs Cold Rolled: Which One Is Right for Your Project?February 26, 2024To optimize the properties of steel for specific applications, it is necessary to consider factors beyond its chemical composition. Hot rolling or cold rolling is a process employed to enhance the sha...view Plastics Solutions: Choosing the Right Materials for Your PartsOctober 18, 2023There are more than 85,000 commercial options for plastics listed in materials databases. Among them, there are 45 polymer families that can be roughly divided into two categories: Thermosets and Thermoplastics. We focus primarily on the latter category, offering hundreds of engineering thermoplastics through our Express Injection Molding service (see Figure 1). In addition to our in-stock plastics, we can handle many other plastics provided by our customers.view

Plastics Solutions: Choosing the Right Materials for Your PartsOctober 18, 2023There are more than 85,000 commercial options for plastics listed in materials databases. Among them, there are 45 polymer families that can be roughly divided into two categories: Thermosets and Thermoplastics. We focus primarily on the latter category, offering hundreds of engineering thermoplastics through our Express Injection Molding service (see Figure 1). In addition to our in-stock plastics, we can handle many other plastics provided by our customers.view