CNC machining comes into contact with many metal materials. Today, let's take a look at the characteristics, applicable techniques, and application areas of these metal materials.

Aluminum is the most abundant metal element in the earth's crust. It appeared in the early 18th century and was first introduced for commercial use in the late 19th century. At that time, it was mainly used to make tableware and kitchenware. It has excellent thermal and electrical conductivity.

Aluminum has a relatively small specific gravity. Compared to most metals, aluminum has a smaller mass in the same volume. At the same time, aluminum has excellent thermal and electrical conductivity, and strong plasticity, and can be changed in shape through various mechanical processing.

The experts have developed aluminum foam, which is a sort of foam aluminum alloy material, and it possesses the benefits of low density, strong impact absorption, high-temperature resistance, strong fireproof performance, corrosion resistance, sound insulation, and noise reduction. Owing to the diverse alloy composition contained in the aluminum, the various heating procedures, and the different vaporized powders acquired during the synthesis of the novel material, the ultimately obtained foam aluminum alloy presents different densities, and the pores of the foam are either large or small.

Aluminum foam is both acoustically and thermally insulated, non-toxic, non-flammable, can be sawn and milled, and screws can be driven into it. This novel material, which is lightweight, strong, and not afraid of fire, can be applied to the veneer of elevator doors and the flooring of train and subway cars. The extruded aluminum bubbles utilized in architecture are also a highly unique design element. The bubbles seem to be frozen on these semi-"melted" metal surfaces, and the panels have varying thicknesses and sound absorption effects. The pore size of the aluminum foam can be regulated via process control during the molding process to achieve diverse surface effects.

Aluminum is an opaque, silvery-white metal with no special odor. Common forms of aluminum include wire, powder, profiles, plates, and rods. It is suitable for die casting, extrusion, drawing, mechanical processing, etc. Aluminum has a wide range of applications, such as automotive, marine, and aerospace components, architectural decorations, and cooling equipment.

Stainless steel is a metal material composed of chromium, nickel, and some other metal elements. As the name suggests, its biggest characteristic is that it is not easy to rust. It was patented by the British in 1916 and has since begun large-scale production. Stainless steel has good corrosion resistance, high temperature resistance, and relatively strong rigidity, and can be polished, drawn, electroplated, and other surface treatments. Stainless steel is widely used in applications such as household products, industrial piping, building structures, tools, and harsh environments. Stainless steel is an opaque, reflective, hard metal material with no odor. Common shapes of stainless steel include rods, plates, profiles, and powders. The main applications of stainless steel in daily life include kitchenware, medical equipment, and mechanical manufacturing. There are many types of stainless steel, so we have compiled a table of the compositions of some commonly used stainless steel for your reference.

Material Composition | Carbon (C) | Silicon (Si) | Manganese (Mn) | Phosphorus (P) | Sulfur (S) | Chromium (Cr) | Nickel (Ni) | Molybdenum (Mo) |

304 Stainless Steel | ≤0.08 | ≤1.00 | ≤2.00 | ≤0.035 | ≤0.03 | ≤18.0-20.0 | ≤8.0-11.0 | |

316 Stainless Steel | ≤0.08 | ≤1.00 | ≤2.00 | ≤0.035 | ≤0.03 | ≤16.0-18.5 | ≤10.0-14.0 | 2.0-3.0 |

430 Stainless Steel | ≤0.12 | ≤0.75 | ≤1.00 | ≤0.04 | ≤0.03 | ≤16.0-18.0 | ||

410 Stainless Steel | ≤0.15 | ≤1.00 | ≤1.00 | ≤0.04 | ≤0.03 | ≤11.5-13.5 |

Applications of stainless steel are categorized into four main types, namely austenitic, ferritic, ferritic and austenitic (composite), and martensite. Also, metal framing material made of austenitic stainless steel is largely employed in household products, industrial piping, and building structures. Martensitic stainless steel is primarily utilized for producing knives and turbine blades. Ferritic stainless steel, which features corrosion resistance, is mostly utilized in durable washing machines and boiler parts. Composite stainless steel, with its stronger anti-corrosion properties, thus is frequently used in aggressive environments.

Copper is one of the earliest discovered and applied metal materials by humans, and it was used in the early days to make weapons and tools. It can be mixed with other metal metal materials near me and applied to various complex working environments. It has excellent conductivity and thermal conductivity. Copper is an opaque metal material, reflective, with a shiny surface. It has no peculiar smell. Common shapes of copper include wire materials, steel sheet metal material, bar materials, etc. It is suitable for handicrafts, casting, sheet metal, CNC processing and other technologies. The application directions of copper are mainly manifested in handicrafts, electronic equipment, military industry supplies, chemical fields, pipeline valves, etc.

Copper’s characteristics include good ductility and softness. It also has good electrical and thermal conductivity, being second only to silver among metal monomers at room temperature. It is easy to form various alloys with other metals having different characteristics. It can be recycled many times without losing its mechanical properties. Moreover, it has a very strong bactericidal effect.

Common coppers include white copper, brass, bronze, etc. White Copper, being a copper-based alloy with nickel as the main additive element, is silvery white, has a metallic luster, and is not easily corroded, with a general nickel content of 25 percent. The addition of nickel enhances such aspects as strength, corrosion resistance, and hardness, and reduces the resistivity temperature coefficient. Thus, the mechanical and physical properties of white copper are exceptionally fine, having good ductility, high hardness, beautiful color, and so on. It is widely applied in various fields and is also an important resistance and thermal. The drawback is that the main additive element - nickel - is a scarce and expensive strategic material.

Brass is an alloy of copper and zinc with good mechanical properties and wear resistance, which can be used in making precision instruments, ship parts, and musical instruments. To improve its corrosion resistance, strength, etc., a small amount of other elements are added to form a complex brass. Bronze is the earliest alloy in the history of metal smelting and casting, with special importance and historical significance. It has a low melting point, high hardness, high plasticity, wear resistance, corrosion resistance, and bright color. It also has the characteristic of "heat shrinkage and cold expansion" and was used in various fields in ancient times. In modern times, bronze is used in industrial products like precision bearings, mechanical parts, and various plates, tubes, and rods.

Titanium is named after the mythological god "Titan" and is known as the embodiment of natural forces, indicating that it is a material metal with excellent properties. It has a very light texture but is highly corrosion-resistant and very tough. It is mainly used in aerospace. Titanium has very high strength, excellent corrosion resistance, and stability. The titanium metal has no beautiful luster, no peculiar smell, and is relatively hard. The shapes of titanium mainly include sheet-like, strip-like, powder-like, etc. It is suitable for technologies such as casting, injection molding, cutting, and CNC processing.

During CNC processing, due to the relatively hard titanium metal and the metallic material fabric it forms, the heat generated during processing is relatively high, and the wear on the cutting tools is relatively large, so generally, the cooling treatment will be strengthened to ensure that the product can reach the dimensions marked on the drawing. The application fields of metallic titanium mainly include some components in the engines, and compressors in airplanes, rockets, and missiles. It is also widely used in the medical industry, such as replaceable human bones, and also in daily life, such as golf clubs and tennis rackets.

Zinc takes on a silvery and slight blue-grey color, and within the application scope of non-ferrous metals, it is second only to materials metal like aluminum and copper. At the same time, it is also a necessary trace element in the human body, and it can also form zinc alloys with other metals to suit some special fields. The melting point of zinc is relatively low, with good fluidity and ease of welding, while also having good mechanical properties and wear resistance.

Products made purely of zinc are hard to find in the market, and it is usually a necessary metal material for alloys or coatings. Zinc castings are also common in daily life. Galvanizing refers to covering a layer of zinc alloy on the surface of the steel piece to achieve the effect of being beautiful and rust-proof.

The greatest application of zinc lies in the galvanizing industry, in which a layer of zinc is plated onto the surface of steel alloy materials with blender metal material for the sake of aesthetic appeal and rust prevention. The chief methods employed are hot-dip galvanizing and electro-galvanizing, both of which are extensively utilized in the automotive, construction, marine, and light industrial sectors. The galvanizing process is multifunctional and can be utilized to produce everything ranging from small rivets and screws to tens of meters of structural building components without the requirement for molds, short production cycles, and low costs.

Zinc is a metal casting mold material that is highly desirable. Zinc possesses an extremely low melting point, and it is this particular property that makes casting so excellent, enabling one to readily and rapidly produce fine and complex parts or accessories from zinc. Zinc alloys are the most probable alternative to plastic among metallic materials.

Magnesium is the lightest used metal in the periodic table of elements, with a specific gravity approximately being 1/4 to 2/3 of that of aluminum. The appearance of magnesium has been around for about 100 years. In the past, due to the characteristics of magnesium being easily corroded and having a high price, it could not be widely used and was only used in the aerospace and military industries, so it was called "precious metal". In recent years, with the development of corrosion resistance technology, places such as China have also begun to produce magnesium alloys on a large scale.

Magnesium possesses a set of remarkable characteristics. It has a lower weight compared to other materials, making it highly advantageous in various applications. It exhibits high specific strength and specific stiffness, indicating its exceptional ability to withstand forces and deformations. Additionally, magnesium offers excellent thermal and electrical conductivity, enabling efficient heat transfer and electrical conduction. It also demonstrates good damping and shock absorption properties, providing effective protection and stability. The material possesses good electromagnetic shielding performance, protecting it from electromagnetic interference. Moreover, magnesium is relatively easy to process and shape, allowing for customization and flexibility in its usage. Finally, it is readily recyclable, adding to its eco-friendliness and sustainability.

At present, magnesium and magnesium alloys have emerged as the largest metal engineering materials following steel and aluminum. Magnesium possesses a comparatively light specific gravity, and it also exhibits higher strength and rigidity. It features good thermal and electrical conductivity, along with favorable damping and shock absorption performance, as well as outstanding electromagnetic shielding performance.

Magnesium can be readily processed and formed, and its exterior presents an opaque color accompanied by a lustrous appearance. Magnesium is predominantly utilized in electronic products, product shells, auto parts' shells, brackets, skeletons, and so forth, and it is also employed in the aerospace and military fields for wheels, oil pumps, pipes, and the like. Simultaneously, it also demonstrates a favorable performance in the medical industry, such as for some implantable items. In daily life, magnesium is utilized to manufacture sports goods, LED lights, and spectacle frames, among others.

Cast iron refers to the carbon alloy metal with a carbon content between 2% and 6.67%. Generally, it is made through pig iron and scrap steel, and the performance of the produced cast iron varies depending on the different ratios of melting. The higher the carbon content, the better its fluidity and it is generally believed that the higher the carbon content in cast iron, the better.

There exist various types of cast iron, each having its particular characteristics and applications. The white cast iron largely incorporates carbon in the form of the carburized body (Fe3C), and its fracture presents a white bright color along with a brittle and hard nature and is scarcely employed on its own. The gray cast iron is currently the most extensively utilized type of cast iron in the industry owing to its low cost, outstanding castability, processability, vibration damping, and intermetallic friction. The malleable cast iron is derived through the graphitizing and annealing of a specific composition of the white cast iron, with the graphite assuming the form of flocculent clusters and possessing higher plasticity compared to the gray cast iron. The ductile iron is a high-performance cast iron derived from the spheroidizing and breeding treatment of the white cast iron, and the precipitated graphite is spherical, thereby earning it the name "ductile iron." Compared to other types of cast iron, the plasticity and toughness of ductile iron are significantly enhanced, allowing it to be utilized in certain ranges to substitute for steel. The petroleum cast iron features a worm-like graphite with a more rounded head, and possesses the advantages of higher strength than the gray cast iron, better casting performance than the ductile iron, as well as good heat resistance and fatigue performance.

Cast iron has excellent mobility, wear resistance, and good machinability. Applicable processing methods include casting, cutting, forging, and so on. The surface of cast iron is reflective, opaque, and relatively hard. Cast iron is generally used more in mechanical engineering, such as the bases of some large equipment, and some parts in the railway are also processed with cast iron. At the same time, there is also the presence of cast iron in daily life, such as the common cast iron pot. Although the heat conduction of the cast iron pot is not fast enough, it can be heated evenly to ensure the original flavor of the object, and it is relatively sturdy and durable.

Gold is also one of the earliest discovered metals by humans, and its appearance is even earlier than copper. Because it is very rare, it is called the "king of metals". For centuries, it has been used by people as currency, value storage, and jewelry. Gold has a relatively high density and melting point. However, gold has very good electrical and thermal conductivity. Its hardness is relatively low and relatively soft, which is convenient for processing. It can also be drawn into gold wire and applied to some special industries. The surface of gold is reflective, opaque, and lustrous.

Gold is mainly used as the currency of international reserves and jewelry. The common gold jewelry is divided into gold and platinum, etc. At the same time, because gold has excellent electrical conductivity, it will also be used as a surface coating. Generally, products that require high electrical conductivity will first electroplate a layer of copper base on the surface, and then carry out the gold plating operation with the metal material in a blender so that the electrical conductivity of the product can be greatly increased.

Gold foil refers to a thin sheet of hammered gold. The conventional process of producing gold foil is grounded on gold bars with 99.99% gold content serving as the primary raw material, which undergoes special processing via over ten procedures like chemical cleaning, hammering, and foil cutting, resulting in a golden color, a shiny and soft texture, a lightweight like a feather, and a thinness like a cicada's wing, with a thickness less than 0.12 micron. Gold foil has a broad range of applications, and the traditional gold paste process is primarily employed to decorate palaces and temples; presently, gold foil has been extensively developed and utilized in numerous fields such as food, makeup, architecture, crafts, and decorative lights.

Silver is a soft, lustrous, white transition metal and also a precious metal. It has been discovered and used in ancient times. Silver has high electrical and thermal conductivity. It has high ductility and a relatively soft texture and is not easily corroded. Silver is mainly used in craft collectibles, jewelry, decorations, high-priced tableware, electroplating materials, medical equipment, etc. Silver is reflective, opaque, and lustrous. Common forms include linear, silver foil, sheet, block, etc. It is suitable for manual processing, stamping, electroplating, embossing and other processes.

Silver is mainly applied in the jewelry design industry, and also has a certain application in the photography industry in industry. The composition of silver contains silver ions, and silver ions have the function of killing viruses. In ancient times, it was used to test whether the food contains toxins. Historically, the Phoenicians would employ silver bottles to contain water, wine, and vinegar in order to prevent the liquid from going bad. In the early 20th century, silver coins were also utilized to allow milk to stay fresh for a longer period, within milk to enable it to remain fresh for a longer time. Presently, silver is being utilized as a valuable antimicrobial agent in a broad range of novel applications, such as dental fillings, surgical needles, catheters, the purification of drinking water (like the use of silver-coated water storage containers in spacecraft), and, most extensively, wound healing.

Tin is a silver-white soft metal, with its main source being cassiterite, produced in places such as China and Malaysia. As the industrial use of tin continues to expand and the smelting and processing technologies of tin constantly enhance, the tin industry has been able to develop rapidly. Tin has good ductility, and it is soft and easy to bend. What’s more, it has a low melting point and is not prone to oxidation, yet this type of metal is readily corroded. Tin is reflective, opaque, and has adjustable luster.

Common forms of tin include blocks, tin foil, and solder wire. Tin foil - Tin possesses a remarkably high degree of ductility and has the capability to be extended into extremely thin tin foil. Normally, individuals utilize tin foil to package cigarettes as well as candy in order to prevent the presence of moisture. However, the ductility of tin is rather poor, and once it is pulled, it fails to be transformed into a fine wire. Due to its good stretching features, tin is not readily oxidized in the air and possesses excellent anti-corrosion properties, and is frequently utilized as an anti-corrosion layer for other metals. Tinplate refers to a steel plate coated with tin on both sides, which imparts the plate with extremely good corrosion resistance. Packaging accounts for 90% of the use of tinplate, and it is also employed for simple toys as it is relatively soft compared to other metals. It is less risky because it is softer than other metals.

It is suitable for processing techniques such as casting and welding. Tin is also used in the coating of electroplating, such as tin plating on the surfaces of iron and copper. In daily life, tin is primarily used as a welding material.

>> How to select the appropriate metal materials for your CNC projects?

A considerable number of metal materials have been presented above, so in practical applications, how ought we to select specific materials? There exist numerous types of metal materials, and the selection of metal materials ought to be based on the requirements and forms of our own products. For instance, if we require to process a product with superior conductivity via CNC, we can opt to use aluminum for processing, and then undertake the surface treatment operation of silver plating. In the case of making some relatively large bases, we can choose cast iron for casting in order to reduce the necessary cost. It is also feasible to seek professional processors for consultation.

Bonus Tip! Choose Richconn to be your reliable partner!

Richconn possesses extremely abundant experience in the CNC metal material processing industry. Regardless of whether your product demands processing techniques such as turning, milling, grinding, wire cutting, or sheet metal, Richconn is capable of fulfilling your requirements. It holds a highly professional engineering and technical team, which has the ability to assist your product in rationally selecting the optimal metal materials.

Richconn helps recommend the right material from its extensive selection of metal materials, which come in different colors, fillings and hardness. Every material it uses comes from reputable suppliers and is thoroughly inspected to ensure they can be matched with a variety of manufacturing styles for sheet metal fabrication. Richconn also takes pride in its high-quality service support, featuring professional technical service support ranging from inquiries to after-sales.

Richconn looks forward to your arrival, and by choosing Richconn, your product can be realized more conveniently and rapidly.

In summary, each type of metal material possesses its own unique characteristics and applications. It is precisely because of the availability of so numerous options for metal materials that our life and production can develop efficiently. Why not start a new project today?

What five axes does the five axes machining center have?March 6, 2023Five-axis machining centers have long been important in the aerospace industry, where machined parts follow the aerodynamic form of the aircraft. Some machines move the rotary axis simply to position ...view

What five axes does the five axes machining center have?March 6, 2023Five-axis machining centers have long been important in the aerospace industry, where machined parts follow the aerodynamic form of the aircraft. Some machines move the rotary axis simply to position ...view Waterborne Aluminum Powder Coating on(Nylon+Fiberglass )Composite Materials: The Innovative Path to the FutureAugust 8, 2023Waterborne aluminum powder coating on nylon+fiberglass composite materials is an ingenious technology that combines nylon and fiberglass to give a unique metallic appearance. This innovative coating t...view

Waterborne Aluminum Powder Coating on(Nylon+Fiberglass )Composite Materials: The Innovative Path to the FutureAugust 8, 2023Waterborne aluminum powder coating on nylon+fiberglass composite materials is an ingenious technology that combines nylon and fiberglass to give a unique metallic appearance. This innovative coating t...view 5-Axis CNC Machining: Faster Speeds and Higher PrecisionJuly 27, 2023One of the ambitious goals of the manufacturing industry is to complete processing in one go: putting a piece of material into a machine tool, running a program, and finally obtaining a perfectly Mach...view

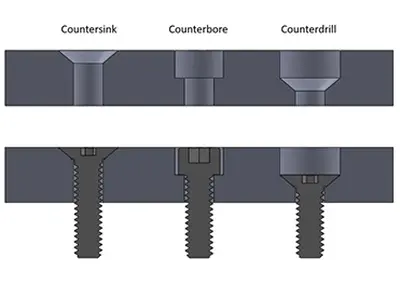

5-Axis CNC Machining: Faster Speeds and Higher PrecisionJuly 27, 2023One of the ambitious goals of the manufacturing industry is to complete processing in one go: putting a piece of material into a machine tool, running a program, and finally obtaining a perfectly Mach...view What is Counter Sink? Your Comprehensive GuideOctober 8, 2023A countersink is a conical hole that is typically drilled or milled into a material, such as wood, metal, or plastic, to allow the head of a screw or fastener to sit flush with or below the surface of the material.view

What is Counter Sink? Your Comprehensive GuideOctober 8, 2023A countersink is a conical hole that is typically drilled or milled into a material, such as wood, metal, or plastic, to allow the head of a screw or fastener to sit flush with or below the surface of the material.view What Is CNC Metal Processing | A Comprehensive GuideJune 4, 2024What is CNC metal processing? What should we pay attention to when choosing a reliable partner for the metal processing project? Here come the answers!view

What Is CNC Metal Processing | A Comprehensive GuideJune 4, 2024What is CNC metal processing? What should we pay attention to when choosing a reliable partner for the metal processing project? Here come the answers!view Do You Know How Anodizing Works?November 4, 2022Anodizing, the process of forming an oxide film on aluminum products (anode) under the action of an applied current under the corresponding electrolyte and specific process conditions of metal or allo...view

Do You Know How Anodizing Works?November 4, 2022Anodizing, the process of forming an oxide film on aluminum products (anode) under the action of an applied current under the corresponding electrolyte and specific process conditions of metal or allo...view