Over the past few years, CNC machining technology has advanced from basic machine tools to more complex ones. Nowadays one of the most cutting-edge techniques accessible is 5-axis CNC machining. It uses subtractive machining to give part production a limitless range of options. This kind of technique makes workpieces cut into the proper shapes and sizes by using cutting tools that operate on five axes. Increased accuracy, efficiency, precision, and dependability are all benefits of 5-axis CNC machining. Want to know some basic knowledge of 5-axis CNC machining? Here we go!

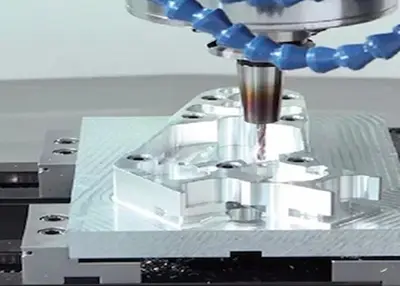

During the process, it can move on three linear axes and two rotational axes at the same time to produce complicated pieces. This usually increases the tilt of the work surface or tool spindle, which can realize the multi-directional machining of the workpiece. Machinists can create 5 faces with a single operation when using a fifth axis, which allows for the quick and easy creation of intricate structures and features and ensures high precision and efficiency.

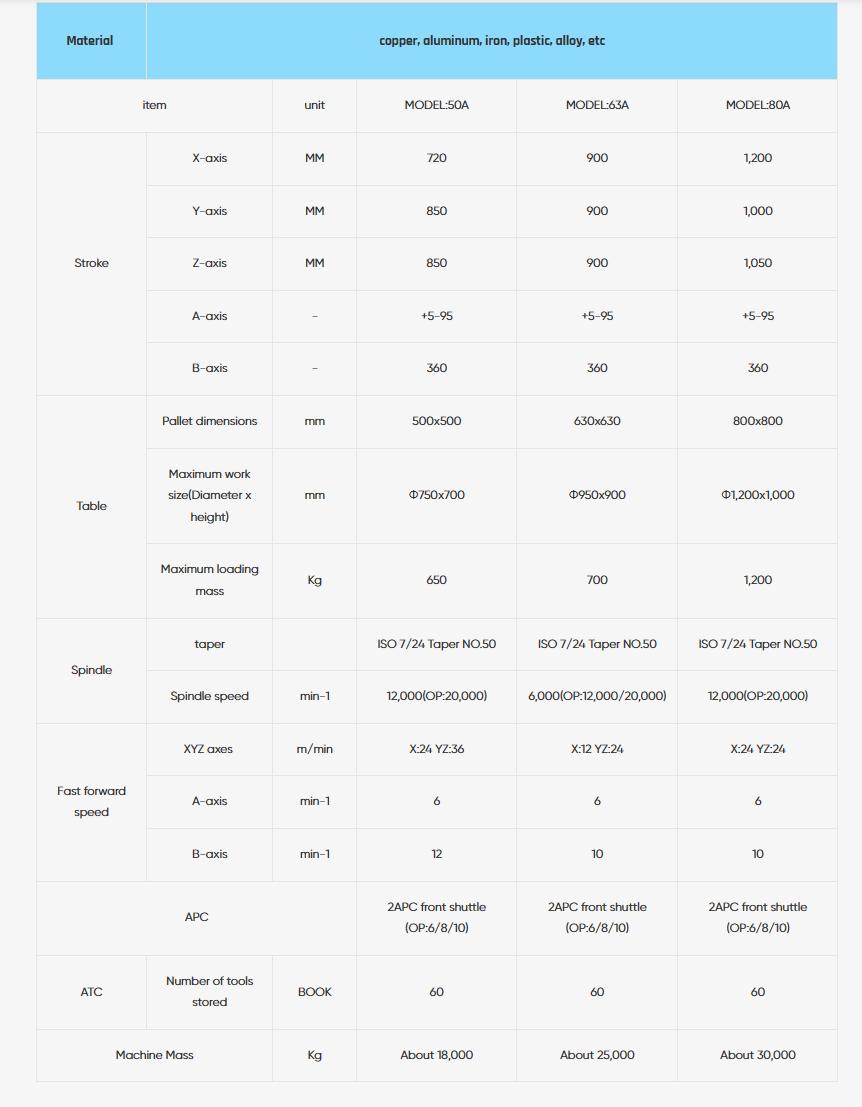

The motion axes of 5-axis CNC machine tools include X-axis, Y-axis, Z-axis, A-axis and B-axis. Among them, the X-axis is the linear axis that moves horizontally while the Y-axis is the linear axis that moves vertically. Besides, the Z-axis is the linear axis that moves up and down. The A-axis and B axis are the rotation axes around the X axis and Y axis.

Through the combined movement of the five axes, the 5-axis CNC machine tool can be machined in multiple directions at the same time, which greatly improves the machining efficiency and accuracy.

No matter large or small 5 axis CNC machine, they all follow computer instructions, just like many other CNC machines. The machine's preset instructions control how the cutting tool and workpiece move. First of all, we need to create a 3D model, and then import the model into CAM software which will turn the model into a computer program. The CNC machine's instructions can be found in it. Besides, it also involves the path of the cutting tool that are made by using the workpiece's geometries. Cutting tool motions along the X-axis, Y-axis, Z-axis, are governed by the instructions. Meanwhile, it can regulate the worktable's direction through A-axis and B-axis so that we can produce the necessary part.

5-axis CNC machine tool is a kind of mechanical equipment with high precision and efficiency and this technology is growing more important for various industries. In order to satisfy different needs of the manufacturing sector, there are numerous types of 5-axis CNC machine. Here, we will introduce three main categories of 5-axis CNC machines.

For this kind of machine, rotational axes are situated in the head. The workpiece is kept in place by its 5-axis apex, which is on a platform that slides through a stationary worktable. As a result, the cutting tool on the head of the machine will not interfere with this process.

This machine is appropriate for manufacturing big, heavy parts because the apex has a larger likelihood of moving around a workpiece. Heavy loads may be supported by the worktable without affecting the accuracy.

There is one rotational axis located in the head of the machine, and the other in the rotary table. The range of the rotational axis located at the head is limited while the axis of rotation located on the workbench is wider. Such a setting has its advantages as well as its limitations. On the one hand, it can continuously rotate the desired parts. On the other hand, the amount of workpiece produced is limited for the reason that it stays on the axis of rotation.

The rotating axes of Table/Table machines are positioned inside the workbench. As a result, the head of the machine won't move, and only the worktable moves. The weakness is that the machine is not proper for processing large or heavy parts because the table cannot bear too much weight. However, it also has its advantages. The operator can easily see how the cutting works due to the fact that the head doesn't move.

5-axis CNC machine plays an extremely important part in manufacturing industry. Here are some advantages of it:

High-precision machining: the 5-axis CNC machine tool has the ability of high-precision motion control, which can realize the high-precision machining of parts and the simulation machining of complex surfaces to ensure the precision and quality of the products.

High machining efficiency: the 5-axis CNC machine tool has the ability of multi-axis simultaneous machining, which can complete the machining of multiple surfaces at one time and thus greatly improves the machining efficiency.

Process innovation: 5-axis CNC machine tools can realize the machining of parts with more complex shapes, which provides more space for process innovation. Through the reasonable optimization of process parameters, more diversified product design and processing can be achieved to meet the needs of different industries and customers.

Reduce labor costs: 5-axis CNC machine tools have a high degree of automation, which can not only shorten the processing cycle, but also reduce manual operation and reduce labor costs. Although 5-axis CNC technology has many advantages, it is not suitable for some applications. Some challenges are as follows.

High cost: the cost of this kind of machine tool is high. Not all small and medium-sized enterprises can afford it.

High skills for operators: 5-axis CNC machine tools have higher requirements for operators who need to have a good command of NC programming and operation skills.

High requirements for the environment: five-axis CNC machine tools also have high requirements for the environment, which requires a stable power supply and suitable working conditions.

Five-axis machining has been widely applied in industries with high accuracy and precision, intricate parts shape and small tolerance.

In the manufacture of aircraft structures, it is necessary to process complex surfaces. The 5-axis CNC machine tool can be accurately machined according to the curved surface profile of the parts to ensure its quality and strength and improve the safety of the aircraft. Because aerospace components are distinctive and geometrically complex, 5-axis machining is the best available technology.

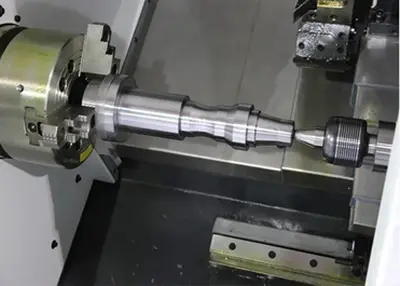

Automobile parts usually need to be processed with complex and high precision to ensure the performance and safety of the car. The 5-axis CNC machine tool can realize the high-precision machining of moving parts, engine parts and other complex parts.

H3: 3. Medical Device Manufacturing

When it comes to creating medical equipment, quality and accuracy are vital. The majority of the parts are tiny and complex. 5-axis CNC machine tools can produce a variety of complex medical device parts to ensure their appropriate size and function. The production of these parts can be done effectively and affordably with the use of 5-axis CNC machine.

Richconn has years of experience in the CNC machining industry and is one of the most skilled 5-axis CNC machining suppliers in China. It offers customized 5-axis CNC machining solutions to meet your specific needs and competitive prices without affecting the quality of the products. When it comes to 5 axis CNC machine price, Richconn is definitely a cost-effective option for your investment in 5-axis CNC.

Don't hesitate to get your OEM CNC machining parts NOW!

(Below is the guidance for 5-axis CNC machining design by Richconn⬇)

5-axis CNC machine tool has become an indispensable important equipment in modern manufacturing industry due to its advantages such as high precision machining, high efficiency, process innovation and flexibility. It has a wide range of applications, and it can meet the processing needs of various industries. What’s more, it provides enterprises with more opportunities for development and innovation. With the continuous progress of science and technology and the deepening of application, 5-axis CNC machine tools will continue to promote the manufacturing industry to a higher level. Quickly start your custom project!

What Workpieces Are Mainly Used for 4-axis CNC Machining?August 10, 2022The continuous improvement of the automation degree of 4-axis CNC machining and the development of mechanized systems make the process scope continue to expand. 4-axis CNC machining maximizes the cont...view

What Workpieces Are Mainly Used for 4-axis CNC Machining?August 10, 2022The continuous improvement of the automation degree of 4-axis CNC machining and the development of mechanized systems make the process scope continue to expand. 4-axis CNC machining maximizes the cont...view Extrusion Blow Molding: A Guide to the Process, Materials, and ApplicationsDecember 5, 2023Extrusion blow molding is a process of forming hollow plastic parts by extruding a molten tube of polymer and inflating it with air inside a mold. It is one of the most common and versatile methods of producing plastic containers, such as bottles, jars, jugs, and drums.view

Extrusion Blow Molding: A Guide to the Process, Materials, and ApplicationsDecember 5, 2023Extrusion blow molding is a process of forming hollow plastic parts by extruding a molten tube of polymer and inflating it with air inside a mold. It is one of the most common and versatile methods of producing plastic containers, such as bottles, jars, jugs, and drums.view Complete List of Machined Hardware Product TypesOctober 19, 2023Hardware: traditional hardware products, also known as "small hardware". Refers to gold, silver, copper, iron, tin five kinds of metal. Artificial processing can be made into knives, swords and other works of art or metal devices. In modern society, hardware is more extensive, such as hardware tools, hardware parts, daily-use hardware, construction hardware and security products. Most of the small hardware products are not final consumer goods.view

Complete List of Machined Hardware Product TypesOctober 19, 2023Hardware: traditional hardware products, also known as "small hardware". Refers to gold, silver, copper, iron, tin five kinds of metal. Artificial processing can be made into knives, swords and other works of art or metal devices. In modern society, hardware is more extensive, such as hardware tools, hardware parts, daily-use hardware, construction hardware and security products. Most of the small hardware products are not final consumer goods.view Metal Plating Finishes: Picking the Best for Your Custom PartsMay 16, 2024What are metal plating finishes? How are they applied? What are their benefits and drawbacks? Find out in this guide to metal plating finishes.view

Metal Plating Finishes: Picking the Best for Your Custom PartsMay 16, 2024What are metal plating finishes? How are they applied? What are their benefits and drawbacks? Find out in this guide to metal plating finishes.view Anodized Aluminum: A Durable and Versatile MaterialJuly 27, 2023Anodized aluminum is a metal with widespread use and advantages. It is a process of treating metal with electricity to create an oxide protective layer on the surface. This layer helps to protect alum...view

Anodized Aluminum: A Durable and Versatile MaterialJuly 27, 2023Anodized aluminum is a metal with widespread use and advantages. It is a process of treating metal with electricity to create an oxide protective layer on the surface. This layer helps to protect alum...view Six Key Points of CNC MachiningApril 4, 2023Many manufacturers know that in the process of CNC machining center, it is crucial to avoid collisions when programming and operating the machine tool. After all, CNC machining centers are not cheap, ...view

Six Key Points of CNC MachiningApril 4, 2023Many manufacturers know that in the process of CNC machining center, it is crucial to avoid collisions when programming and operating the machine tool. After all, CNC machining centers are not cheap, ...view

EN

EN

ru

ru