In a tank filled with metal powder, a computer-controlled high-power carbon dioxide laser selectively sweeps the surface of the metal powder. Wherever the laser goes, the metal powder on the surface is completely melted and bonded together, and the powdery state remains where it is not illuminated. The whole process needs to be carried out in a sealed chamber filled with inert gas.

Selective laser sintering CNC metal machining is that the SLS method uses infrared lasers as energy sources, and the modeling materials used are mostly powder materials. When processing, the powder is first preheated to a temperature slightly lower than its melting point, and then the powder is flattened under the action of a leveling stick; the laser beam is selectively sintered according to the layered section information under computer control, and one layer is completed. Then the next layer of sintering is carried out. After all the sintering is completed, the excess powder is removed, and the sintered parts can be obtained. At present, the mature process materials are wax powder and plastic powder, and the process of sintering with metal powder or ceramic powder is still under study.

Similar to "squeeze cream" style fused deposition, but instead sprays metal powder. While spraying metal powder materials, the nozzle also provides high-power laser and inert gas protection. This will not be limited by the size of the metal powder box, and can directly manufacture larger-volume parts, and it is also very suitable for repairing partially damaged precision parts.

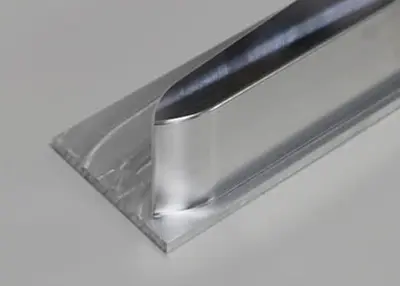

The metalworking roll forming method uses a series of continuous stands to roll stainless steel into complex shapes. The sequence of rolls is designed so that the roll profile of each stand continuously deforms the metal until the desired final shape is obtained. If the shape of the part is complex, up to thirty-six racks can be used, but for the simple-shaped part, three or four racks are sufficient.

Die forging refers to a forging CNC metal machining method that uses a die to form a blank on a special die forging equipment to obtain a forging. The forgings produced by this method are accurate in size, small in machining allowance, complex in structure and high in productivity.

That is, the blanking process, the film formed in the previous process is positioned on the male die of the punching die, the excess material is removed by clamping the die, and the 3D shape of the product is retained to match the die cavity.

In the die cutting process, the film panel or circuit is positioned on the bottom plate, the die die is fixed on the template on the machine, and the force provided by the machine's downward pressure is used to control the blade to cut the material. The difference between it and the punching die is that the incision is smoother; at the same time, by adjusting the cutting pressure and depth, the effects of indentation and half-break can be punched out. At the same time, the low-cost operation of CNC metal machining molds is more convenient, safe and fast.

What Is Galvanized Sheet Metal? The Complete Basics to Get StartedOctober 12, 2023Galvanized sheet metal is one of the most cost-effective and popular types of metal in the market. Here are the complete basics about it for you to get started.view

What Is Galvanized Sheet Metal? The Complete Basics to Get StartedOctober 12, 2023Galvanized sheet metal is one of the most cost-effective and popular types of metal in the market. Here are the complete basics about it for you to get started.view How to Define Fits: Different Types of Fits in EngineeringMarch 5, 2024This article will shade some light on “fits”. To know more about “what is fits” will help you succeed in doing your projects. So let’s check it out.view

How to Define Fits: Different Types of Fits in EngineeringMarch 5, 2024This article will shade some light on “fits”. To know more about “what is fits” will help you succeed in doing your projects. So let’s check it out.view Key Points in Precision Mold Processing TechnologyJuly 21, 2023Precision mold making is a crucial process that requires specialized skills, knowledge, and tools. It involves the creation of tools that are used to produce other parts or products. The quality of th...view

Key Points in Precision Mold Processing TechnologyJuly 21, 2023Precision mold making is a crucial process that requires specialized skills, knowledge, and tools. It involves the creation of tools that are used to produce other parts or products. The quality of th...view What Are the Types of Metal Surface Finish?September 16, 2022Machining surface finishing is an important processing procedure in machining. Machining surface finish can play an important role in protecting and beautifying the workpiece. In machining, there are ...view

What Are the Types of Metal Surface Finish?September 16, 2022Machining surface finishing is an important processing procedure in machining. Machining surface finish can play an important role in protecting and beautifying the workpiece. In machining, there are ...view Tips On How to Find Low Cost CNC Milling ServicesOctober 24, 2023CNC milling services are not cheap. The more accurate the design you need, the more money you can expect to spend. Reliable machine shops employ professional operators who use state-of-the-art equipment to fulfill orders. As a result, you can't afford to ignore your budget in order to shorten lead times or gain a competitive edge.view

Tips On How to Find Low Cost CNC Milling ServicesOctober 24, 2023CNC milling services are not cheap. The more accurate the design you need, the more money you can expect to spend. Reliable machine shops employ professional operators who use state-of-the-art equipment to fulfill orders. As a result, you can't afford to ignore your budget in order to shorten lead times or gain a competitive edge.view Spray Paint or Powder Coating? The Ultimate Showdown for Surface Treatment of Machined Parts to Find the Best Solution!July 12, 2023IntroductionIn past communications with customers, we often encounter these situations:1. The customer's drawings only specify the color, without specific requirements. 2. The customer's techn...view

Spray Paint or Powder Coating? The Ultimate Showdown for Surface Treatment of Machined Parts to Find the Best Solution!July 12, 2023IntroductionIn past communications with customers, we often encounter these situations:1. The customer's drawings only specify the color, without specific requirements. 2. The customer's techn...view

EN

EN

ru

ru