In the heart of precision manufacturing, CNC (Computer Numerical Control) lathe machining stands as a true marvel. It's a technology that has transformed the way we create parts and components across various industries.

CNC lathes are automated machines that use computer programming to control the movement and operation of the cutting tools. The primary objective is to achieve precise and repetitive machining, something that manual machining can't compete with.

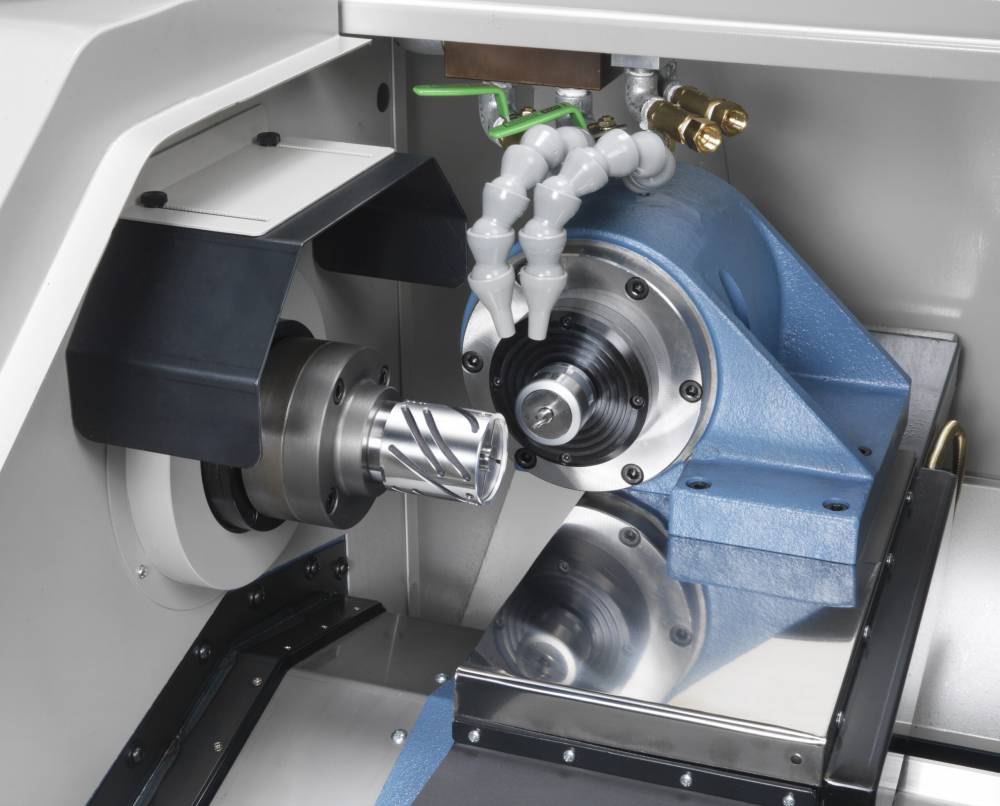

CNC Lathe Definition: CNC lathe machines are automated precision tools used for shaping materials, primarily metal, into desired forms.

History of CNC Lathes: The journey from manual lathes to CNC precision.

Key Components: Understand the critical elements of a CNC lathe machine.

CNC Lathe Operation: How a CNC lathe machine functions in detail.

Precision Manufacturing: The primary objective of CNC lathes.

Benefits Over Manual Machining: Exploring the advantages of CNC lathe machining.

Automated Efficiency: How automation improves productivity and reduces human error.

Versatility in Material and Shape: The ability to work with diverse materials and complex geometries.

Material Compatibility: Metals, plastics, and more.

Application Range: Aerospace, automotive, medical, electronics, and more.

Complex Geometries: Detailed components and intricate designs.

High-Speed Machining: Efficient production processes.

One of the first things to understand is the difference between CNC and traditional machining methods.

Precision and repeatability are the hallmarks.

Automated and controlled by computer programming.

Ideal for complex geometries and intricate designs.

Less human intervention reduces errors and increases efficiency.

Manual control by skilled machinists.

Suitable for simple and small-scale operations.

High skill level required, leading to variations in quality.

Limited in terms of speed and complexity.

| Aspect | CNC Machining | Traditional Machining |

|---|---|---|

| Precision and Accuracy | Exceptional precision | Depends on the skill of machinist |

| Automation | Controlled by computer | Manual operation by machinist |

| Complexity | Ideal for intricate designs | Limited to simple operations |

| Efficiency | Reduced human errors | Skill-dependent quality control |

| Speed | Faster production cycles | Slower production rates |

Understanding the needs of your project.

Evaluating cost-effectiveness.

Balancing precision, time, and skill requirements.

CNC lathe machining is a powerhouse that finds applications in a wide range of industries. Let's explore some key areas where it plays a crucial role:

Mass production of components and parts.

Consistent quality and accuracy.

Enhanced production rates.

Manufacturing engine parts, shafts, and gears.

High precision for optimal vehicle performance.

Enhanced safety and reliability.

Crafting complex and lightweight components.

Meeting strict industry regulations.

Reducing weight for fuel efficiency.

| Industry | Key Applications |

|---|---|

| Manufacturing | Mass production, precision parts |

| Automotive | Engine components, precision gears |

| Aerospace | Complex lightweight parts, regulatory compliance |

Creating intricate and sterile components.

Precision for life-saving equipment.

Compliance with medical standards.

Crafting microelectronic components.

Precision for high-speed data transmission.

Miniaturization and efficiency.

In the world of precision machining, CNC lathes have emerged as the preferred choice for several compelling reasons:

CNC lathes offer unmatched precision, ensuring that each component meets the required specifications.

High repeatability, reducing variations in parts.

Ideal for applications demanding precise tolerances.

Automation eliminates manual labor, resulting in quicker production cycles and reduced lead times.

Higher spindle speeds and rapid tool changes enhance productivity.

Consistent quality leads to fewer reworks and delays.

CNC lathes can handle a wide variety of materials, shapes, and sizes, making them suitable for diverse applications.

Quick adaptability to different tasks through reprogramming.

Reduced setup time for changeovers.

Consistency is guaranteed, reducing the chances of defects and ensuring that each piece matches the previous one perfectly.

Lower scrap rates, leading to cost savings.

Ideal for long production runs.

Easily reprogrammed for different tasks, making them a versatile solution for dynamic industries.

Rapid adaptation to design changes.

Facilitates continuous improvement and innovation.

When it comes to harnessing the power of CNC machining, one name that stands out is Richconn. As a leading precision machine works, Richconn offers an array of advantages for your manufacturing needs:

Richconn employs the latest CNC machining technology, ensuring the highest level of precision and efficiency.

State-of-the-art machinery and software for unmatched results.

Investment in innovation for continuous improvement.

From small intricate components to large-scale production, Richconn caters to a wide range of industries and needs.

Customizable solutions to meet unique project requirements.

A vast portfolio of successful projects across various sectors.

Numerous satisfied clients vouch for Richconn's commitment to quality and exceptional customer service.

Success stories and case studies showcasing their capabilities.

Reputation for reliability and timely deliveries.

Ready to experience the excellence of CNC machining? Contact Richconn today to explore their services and how they can meet your unique requirements.

Consultation services to assess your project and provide tailored solutions.

Transparent communication and collaboration to ensure project success.

CNC lathe machining is a revolutionary technology that has transformed the manufacturing landscape. Its precision, efficiency, and adaptability make it the preferred choice for various industries. If you're ready to take your manufacturing to the next level, explore the CNC machining services offered by Richconn and witness the future of precision manufacturing in action. Your journey towards excellence begins now!

Take the first step towards precision and efficiency in manufacturing.

Contact Richconn for a consultation tailored to your project needs.

Experience the benefits of CNC lathe machining firsthand.

Elevate your production capabilities with cutting-edge technology.

The Intersection of Chameleon PVD Coating and GadgetsJanuary 5, 2024Innovations in technology have paved the way for stunning advancements in the gadget industry. One such breakthrough that mesmerizes tech enthusiasts is the thrilling use of Chameleon PVD coating. Wit...view

The Intersection of Chameleon PVD Coating and GadgetsJanuary 5, 2024Innovations in technology have paved the way for stunning advancements in the gadget industry. One such breakthrough that mesmerizes tech enthusiasts is the thrilling use of Chameleon PVD coating. Wit...view What Is Titanium? (Definition and Guide)February 26, 2024How to choose titanium for your project? Familiarize yourself with the various titanium grades and learn how to choose the most suitable grade for your needs.view

What Is Titanium? (Definition and Guide)February 26, 2024How to choose titanium for your project? Familiarize yourself with the various titanium grades and learn how to choose the most suitable grade for your needs.view All the Information You Need to Know About Polishing Surface FinishMarch 1, 2024Here is all the information. Learn more about the necessary details to guarantee your project's success. Check it out.view

All the Information You Need to Know About Polishing Surface FinishMarch 1, 2024Here is all the information. Learn more about the necessary details to guarantee your project's success. Check it out.view CNC Automotive Parts: A Complete Analysis of Manufacturing and ApplicationsSeptember 22, 2023CNC auto parts, known as Computer Numerical Control (CNC) auto parts, are one of the key components in the automotive manufacturing and repair process.view

CNC Automotive Parts: A Complete Analysis of Manufacturing and ApplicationsSeptember 22, 2023CNC auto parts, known as Computer Numerical Control (CNC) auto parts, are one of the key components in the automotive manufacturing and repair process.view Boring Machining Process GuideNovember 22, 2023In CNC machining, boring technology is used as a precision machining process with a spindle mounted sleeve. Boring is a machining process in which the internal surface of a workpiece is cut by a rotating tool on a boring machine to determine the precise hole diameter and surface quality.view

Boring Machining Process GuideNovember 22, 2023In CNC machining, boring technology is used as a precision machining process with a spindle mounted sleeve. Boring is a machining process in which the internal surface of a workpiece is cut by a rotating tool on a boring machine to determine the precise hole diameter and surface quality.view Implant Abutment Materials and SelectionOctober 24, 2023Commonly used implant abutment materials can be divided into five categories: titanium (precision machining, polished, laser etched), surgical grade stainless steel, cast gold alloys, zirconium oxide, and polyether ether ketone (PEEK).view

Implant Abutment Materials and SelectionOctober 24, 2023Commonly used implant abutment materials can be divided into five categories: titanium (precision machining, polished, laser etched), surgical grade stainless steel, cast gold alloys, zirconium oxide, and polyether ether ketone (PEEK).view

EN

EN

ru

ru