Chrome plating is a common metal finish that improves the wear resistance, corrosion resistance, aesthetics and hardness of the metal. However, sometimes chrome plating needs to be removed in order to repair, replace or refinish the metal. So, how do you remove chrome plating? In this article, we will introduce what is chrome plating layer, why do we need to remove chrome plating layer, and several methods of how to remove chrome plating layer, which we hope will be helpful to you.

Chrome plating is a process of covering a metal surface with a thin layer of chromium by electroplating or chemical plating. The purpose of chrome plating is to improve the wear resistance, corrosion resistance, aesthetics and hardness of the metal. The thickness of the chrome plating layer is generally between a few microns and tens of microns, and can be classified as decorative chrome plating and hard chrome plating depending on its use and requirements.

Decorative chrome plating refers to plating a layer of chromium with a thickness of less than 0.5 microns on the metal surface, which is mainly used to improve the luster and aesthetics of the metal, such as chrome-plated parts of automobiles, bicycles, furniture, and so on. The chromium layer of decorative chromium plating is generally applied on top of a layer of nickel to increase its adhesion and corrosion resistance.

Hard chrome plating refers to the plating of a layer of chromium with a thickness of 10 microns or more on the surface of a metal, which is mainly used to improve the abrasion resistance and hardness of the metal, such as chrome-plated parts for machinery, tools, molds and so on. The chromium layer of hard chrome plating is usually applied directly to the metal substrate to increase its strength and stiffness.

Although chrome plating has many advantages, it also has some disadvantages and sometimes it is necessary to remove the chrome plating for several reasons:

- The chrome layer is damaged or worn, affecting the appearance and performance of the metal, and needs to be removed and re-chromed or repainted.

- Peeling or oxidation between the chrome layer and the metal substrate, resulting in corrosion or discoloration of the metal, which needs to be removed and then repaired or replaced.

- The thickness or quality of the chrome plating layer does not meet the requirements, affecting the size or accuracy of the metal, requiring readjustment or machining after removal.

- The composition or nature of the chromium plating layer is not suitable for certain applications or environments, e.g. it is harmful to human body or the environment, and needs to be replaced or processed after removal.

There are many ways to remove chrome plating, which can be categorized into the following three depending on their principles and effects:

Mechanical removal method refers to the method of removing the chrome layer by grinding or scraping the metal surface using mechanical force, such as grinding wheels, wire brushes, sandpaper, and so on. The advantages of the mechanical removal method are that it is easy to operate, fast, low cost and does not produce toxic waste liquid. The disadvantage of the mechanical removal method is that it may damage the metal substrate, reduce the surface quality and precision of the metal, and is not suitable for removing complex or fine chrome-plated parts.

Chemical removal method refers to the use of chemical reactions, such as acid and alkali, redox, etc., to corrode or dissolve the metal surface, so as to remove the chrome layer. The advantages of the chemical removal method are that it can remove chrome-plated parts of any shape or size without damaging the metal substrate, and that the speed and depth of removal can be controlled. The disadvantages of chemical removal are that it is complicated to operate, requires the use of specialized equipment and medicines, and produces toxic waste liquids, which are hazardous to human beings and the environment.

Electrolytic removal method refers to the use of electric current, so that the metal surface electrochemical reaction, so as to remove the chrome layer. The principle of the electrolytic removal method is to use the chromium-plated part as the cathode, connect it with the anode (e.g., copper plate), put it into an electrolytic solution (e.g., sulphate solution), and pass it through direct current, so that the chromium layer is detached from the cathode and deposited on the anode. The advantages of the electrolytic removal method are that it can remove chromium-plated parts of any shape or size without damaging the metal substrate, and that the chromium layer can be recovered, reducing contamination. The disadvantages of electrolytic removal are that it is complicated to operate, requires the use of specialized equipment and power supplies, and generates a certain amount of heat and gas.

The need of removing chrome layer does not only occur in mass production requirements, sometimes we also have the need of removing chrome layer ourselves in our home life, but it is too costly to go to a professional organization for our personal needs, so removing the chrome layer can also be done at home, here is the video where we share how to remove chrome layer at home by ourselves:

Chrome plating layer is a common metal surface finishing that improves wear resistance, corrosion resistance, aesthetics, and hardness of the metal. However, sometimes it is necessary to remove the chrome plating for several reasons: the chrome plating is damaged or worn, the chrome plating peels or oxidizes between the chrome plating and the metal substrate, the thickness or quality of the chrome plating does not meet the requirements, and the composition or nature of the chrome plating is unsuitable for certain applications or environments. There are many methods for removing chrome plating, which can be categorized into the following three depending on their principles and effects: mechanical removal, chemical removal, and electrolytic removal. Each method has its advantages and disadvantages, and it is necessary to choose the appropriate method according to the specific situation and requirements in order to achieve the best results.

Features Of CNC MillingJune 21, 2022CNC milling is generally a metal fabrication process; however, plastics can also be machined. CNC milling uses a computer to control the tool. The cutting tool then cuts the material from the workpiec...view

Features Of CNC MillingJune 21, 2022CNC milling is generally a metal fabrication process; however, plastics can also be machined. CNC milling uses a computer to control the tool. The cutting tool then cuts the material from the workpiec...view Material Properties in More DetailOctober 18, 2023The functionality of a part is largely dependent on obvious factors such as shape, size, wall thickness, joints, etc. Less obvious, but equally important, are the properties of the material from which it is injection molded, CNC machined, or 3D printed (cut, bent, formed, etc.).view

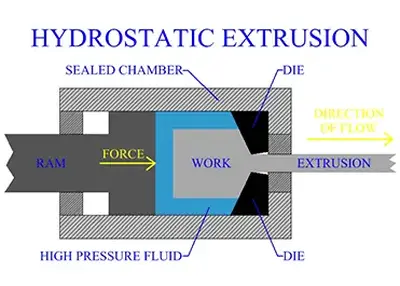

Material Properties in More DetailOctober 18, 2023The functionality of a part is largely dependent on obvious factors such as shape, size, wall thickness, joints, etc. Less obvious, but equally important, are the properties of the material from which it is injection molded, CNC machined, or 3D printed (cut, bent, formed, etc.).view Extrusion: A Manufacturing Process for Creating Various Shapes and ProductsNovember 30, 2023what is extrusion?Extrusion is a process of forcing a material through a die or a nozzle to create a continuous shape or product. The material can be solid, liquid, or semi-solid, and it can be metal,...view

Extrusion: A Manufacturing Process for Creating Various Shapes and ProductsNovember 30, 2023what is extrusion?Extrusion is a process of forcing a material through a die or a nozzle to create a continuous shape or product. The material can be solid, liquid, or semi-solid, and it can be metal,...view 6 Avoidable Mistakes When Designing CNC PartsOctober 13, 2023A common mistake is designing parts with surfaces where material removal would actually be unnecessary. Unnecessary machining contributes to longer machining times, and that greatly impacts the final production cost.view

6 Avoidable Mistakes When Designing CNC PartsOctober 13, 2023A common mistake is designing parts with surfaces where material removal would actually be unnecessary. Unnecessary machining contributes to longer machining times, and that greatly impacts the final production cost.view Common Impact Resistant Plastics.October 17, 2023Tough. Unbreakable. Resistant to punctures and cracks from impact. That's how some people describe impact-resistant plastic. However, as you will see, this term is ambiguous. Just because a piece of chewing gum doesn't break in half when you hit it with a hammer doesn't mean it's impact resistant. Put the same gum in the freezer for a while and then hit it. Only splinters.view

Common Impact Resistant Plastics.October 17, 2023Tough. Unbreakable. Resistant to punctures and cracks from impact. That's how some people describe impact-resistant plastic. However, as you will see, this term is ambiguous. Just because a piece of chewing gum doesn't break in half when you hit it with a hammer doesn't mean it's impact resistant. Put the same gum in the freezer for a while and then hit it. Only splinters.view PVD Surface Treatment: Achieving Durability and AestheticsAugust 14, 2023PVD (Physical Vapor Deposition) surface treatment process is usually used to create hard, durable and beautiful surfaces. It involves applying a thin layer of metal or ceramic coating onto an object t...view

PVD Surface Treatment: Achieving Durability and AestheticsAugust 14, 2023PVD (Physical Vapor Deposition) surface treatment process is usually used to create hard, durable and beautiful surfaces. It involves applying a thin layer of metal or ceramic coating onto an object t...view

EN

EN

ru

ru