Welcome to the world of precision engineering, where every turn counts. As a CNC machining enthusiast, I invite you on a journey to uncover the subtleties between internal turning and external turning - two pivotal techniques shaping the art of machining.

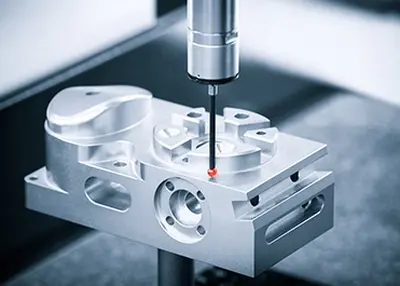

Internal turning stands as the cornerstone of precise machining, a technique that delves deep into the heart of workpieces, sculpting their inner intricacies with finesse. Unlike external turning, this method involves maneuvering cutting tools within the confines of the workpiece, shaping internal features to meticulous specifications. The precision achieved in internal turning is unparalleled, catering to industries demanding utmost accuracy in components, from automotive cylinders to aerospace components.

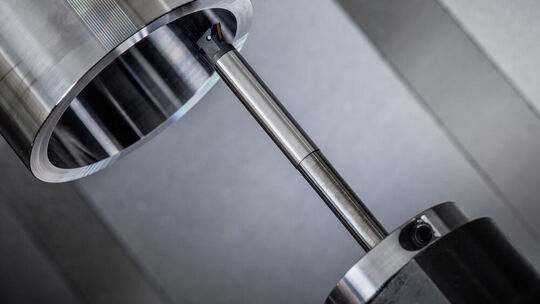

External turning, on the other hand, epitomizes precision that meets the eye. It revolves around the outer contours of workpieces, refining surfaces and shaping the exterior with precision. By employing cutting tools on the outer surface of the workpiece, external turning crafts the foundational form and structure of components, ensuring dimensional accuracy and surface finish. This technique finds extensive use across industries, contributing significantly to the production of shafts, cylinders, and various structural elements.

Internal turning demands specialized tooling and techniques, navigating the confined spaces within workpieces. The tools maneuver with precision, sculpting intricate features like holes, bores, and internal threads. Its unique challenges involve tool accessibility and chip evacuation, requiring tailored solutions for each workpiece's internal contours. Achieving optimal cutting angles and tool stability is crucial to ensuring the desired precision.

In external turning, the focus lies on the workpiece's exterior surfaces. The cutting tools, positioned outside the workpiece, sculpt the outer contours, ensuring dimensional accuracy and surface finish. Challenges here include managing tool wear and optimizing cutting speeds to achieve consistent results across varied materials and geometries.

The precision achieved in internal turning is a testament to its meticulous approach. This technique excels in achieving tight tolerances and intricate details within workpieces, ensuring the internal features meet exacting specifications. Surface finish and dimensional accuracy are meticulously controlled, catering to industries where microns matter.

External turning, while focusing on the exterior, maintains stringent standards in surface quality. Achieving smooth finishes and precise dimensions on outer surfaces is critical. Techniques like tool selection, feed rates, and cutting parameters significantly impact the final surface quality, influencing the functional and aesthetic aspects of the components.

Internal turning finds its niche in industries demanding intricate components, such as aerospace and medical devices. In aerospace, it's instrumental in crafting engine components, ensuring high-precision internal features critical for optimal performance. Similarly, in the medical sector, internal turning aids in creating precise implants and surgical instruments, where accuracy is paramount.

With advancements in materials like superalloys and composite materials, internal turning has evolved to handle the challenges posed by these cutting-edge materials. Its adaptability to diverse materials positions it as a key player in the manufacturing of components in modern industries.

External turning serves as the backbone of manufacturing, catering to a wide array of components across industries. From turning shafts in automotive applications to creating structural elements in construction, its versatility shines. External turning plays a pivotal role in producing components that form the backbone of various systems.

In high-volume production scenarios, external turning’s efficiency and precision stand out. It ensures consistency in producing large quantities of components with uniform dimensions and surface finish. This efficiency makes it indispensable in industries demanding mass production without compromising quality.

Achieving mastery in internal turning demands a meticulous approach. Optimizing cutting parameters, tool selection, and coolant usage significantly impact performance. Strategies like adaptive machining and toolpath optimization enhance efficiency while ensuring precision in complex internal geometries.

Addressing challenges like chip evacuation and tool accessibility requires innovative solutions. Specialized tool designs, such as slim shank tools and customized inserts, mitigate challenges associated with limited space, enabling smoother operations within confined areas.

External turning efficiency hinges on optimizing cutting speeds, feed rates, and tool geometries. Employing precision tooling and advanced machining strategies, such as high speed machining, maximizes efficiency while maintaining quality.

Embracing technological advancements like real-time monitoring and adaptive tooling elevates external turning's capabilities. Predictive maintenance and AI-driven machining optimize tool life and machining accuracy, enhancing the overall process efficiency.

At Richconn, our proficiency in internal turning is showcased through tailored solutions and a track record of delivering precision-crafted components. Our specialized tooling and expertise in maneuvering within confined spaces ensure superior quality and accuracy.

In external turning, Richconn's prowess is evident in our ability to handle diverse components across industries. Our precision tooling, optimized machining strategies, and commitment to quality underscore our excellence in delivering superior external turning solutions.

Richconn stands as a testament to precision and expertise in CNC machining. With a commitment to innovation and a track record of delivering superior solutions in both internal and external turning, we strive to be your trusted partner in achieving precision-driven excellence.

How to Go About Choosing an Aluminum Alloy Mechanical Keyboard Shell Processing Manufacturer?October 26, 2023For computer enthusiasts, the mechanical keyboard's metal texture and the sound of that mechanical equipment is a keyboard users a kind of enjoyment, mechanical keyboard bezel styling design is one of my favorite hardware configurations, especially glazed, computer typing is very indulgent.view

How to Go About Choosing an Aluminum Alloy Mechanical Keyboard Shell Processing Manufacturer?October 26, 2023For computer enthusiasts, the mechanical keyboard's metal texture and the sound of that mechanical equipment is a keyboard users a kind of enjoyment, mechanical keyboard bezel styling design is one of my favorite hardware configurations, especially glazed, computer typing is very indulgent.view Unveiling the Precision World of Machined Gears: A Richconn PerspectiveNovember 10, 2023In the intricate tapestry of mechanical engineering, machined gears stand as the unsung heroes, translating rotational motion with unparalleled precision. These gears are meticulously crafted to meet the demanding requirements of various industries, ensuring seamless operation in complex machinery.view

Unveiling the Precision World of Machined Gears: A Richconn PerspectiveNovember 10, 2023In the intricate tapestry of mechanical engineering, machined gears stand as the unsung heroes, translating rotational motion with unparalleled precision. These gears are meticulously crafted to meet the demanding requirements of various industries, ensuring seamless operation in complex machinery.view CNC Machining Aerospace Parts: The Manufacturing Key to High-precision EngineeringSeptember 22, 2023As an avid fan of aerospace technology, I'm excited to take you into the world of CNC machining of aerospace parts, where precision meets innovation.view

CNC Machining Aerospace Parts: The Manufacturing Key to High-precision EngineeringSeptember 22, 2023As an avid fan of aerospace technology, I'm excited to take you into the world of CNC machining of aerospace parts, where precision meets innovation.view Can Titanium Be Machined: Comprehensive analysis of CNC machining of titanium materialsNovember 10, 2023Greetings, machining enthusiasts! Have you ever wondered if titanium, that resilient and lightweight metal, can truly be harnessed through CNC machining? I'm here to not only answer your burning question but to delve into the intricacies, challenges, and best practices associated with machining titanium. As Richconn, your go-to precision machine shop, let's unlock the full potential of this extraordinary material together.view

Can Titanium Be Machined: Comprehensive analysis of CNC machining of titanium materialsNovember 10, 2023Greetings, machining enthusiasts! Have you ever wondered if titanium, that resilient and lightweight metal, can truly be harnessed through CNC machining? I'm here to not only answer your burning question but to delve into the intricacies, challenges, and best practices associated with machining titanium. As Richconn, your go-to precision machine shop, let's unlock the full potential of this extraordinary material together.view DESIGN TIP: Thermoplastics and Thermosets in ComparisonOctober 18, 2023There are two main categories of plastic materials: thermoplastics and thermosets, which differ in their behavior under heat. In this design tip, we present a few considerations to keep in mind when using these materials.view

DESIGN TIP: Thermoplastics and Thermosets in ComparisonOctober 18, 2023There are two main categories of plastic materials: thermoplastics and thermosets, which differ in their behavior under heat. In this design tip, we present a few considerations to keep in mind when using these materials.view Beyond Aesthetics: The Practical Benefits of Blackening Surface TreatmentDecember 4, 2023When it comes to surface treatments for various metal components, one often thinks about aesthetics and corrosion resistance as the primary goals. However, there is another important surface treatment...view

Beyond Aesthetics: The Practical Benefits of Blackening Surface TreatmentDecember 4, 2023When it comes to surface treatments for various metal components, one often thinks about aesthetics and corrosion resistance as the primary goals. However, there is another important surface treatment...view

EN

EN

ru

ru