Have you ever imagined that with just a few clicks, you can turn your ideas into reality? 3D printing, this amazing technology, is changing our lives. From healthcare to aerospace, from fashion to architecture, its applications are everywhere. Wondering how 3D printing works and what its astonishing advantages are? Let's explore the mysteries of 3D printing together!

3D printing, which is also called additive manufacturing, refers to the process of creating a 3D object based on a digital design. In contrast to traditional subtractive methods, 3D printing is an additive one. It begins with a solid object and then modifies it to reach the desired design. Fundamentally, the 3D printer utilizes a digital plan to shape a physical product. Take some 3D printers for example, they use a heated material, such as plastic, to generate layers that are placed one on top of another, and these layers ultimately build up in three-dimensional space to form an object. 3D printing was first brought in the late 1980s, but it didn't attract significant attention until the 1990s. Just like any other new technology, at first, many people considered 3D printing to be something that could only exist in science fiction. But now, 3D printing has gained momentum and is being incorporated into various industries.

There are various materials that a 3D printer utilizes to reproduce an object to the best of its ability. Here are some examples of 3D printing materials: Acrylonitrile Butadiene Styrene (ABS), a plastic material that is easy to mold and hard to break, the same material that LEGOs are made of. Carbon Fiber Filaments are used to create objects that need to be strong and extremely lightweight. Conductive Filaments, these printable materials are still in the experimental stage and can be used to print electrical circuits without the need for wires, making them useful for wearable technology. Flexible Filaments produce prints that are flexible yet tough, and can be used to print anything from wristwatches to phone cases. Metal Filaments, which are made of finely ground metals and polymer glue, and can be available in steel, brass, bronze, and copper to give the true appearance and feel of a metal object. Wood Filament, these filaments contain finely ground wood powder mixed with polymer glue and are obviously used to print objects that look like wood and can appear as light or dark wood depending on the temperature of the printer.

3D printing has many advantages. It can not only make the process of manufacturing complex parts more efficient but also relatively affordable. It can also quickly make product prototypes and can use various special materials to meet different needs. Let's take a look.

3D printers are relatively inexpensive. Thanks to software programming, 3D printing can make the manufacturing process of complex parts more efficient, which often makes it a more cost-effective option in some industries. Additionally, the materials used in 3D printing are relatively inexpensive, such as low-cost plastics and concrete that are readily available. Moreover, since there is no need for a mold in 3D printing, this is another cost-saving factor. 3D printers are speedy.

3D printing is perfect for quickly prototyping products, as it can be done in-house in small batches. This enables manufacturers to identify and fix problems and make adjustments to products more quickly than in a typical production process. Changes to products can be easily made via CAD while the manufacturing cost remains the same.

3D printers can work with specialized materials. Despite the common use of plastics and metals in the 3D printing industry, there are many other options available. This advantage means that specialized parts and products can be made using specific materials, such as water-absorbing plastic, nitinol, gold, and carbon fiber. Specialized materials like these offer properties such as high heat resistance, water repellency, and strength.

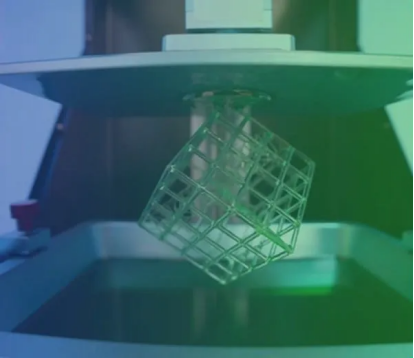

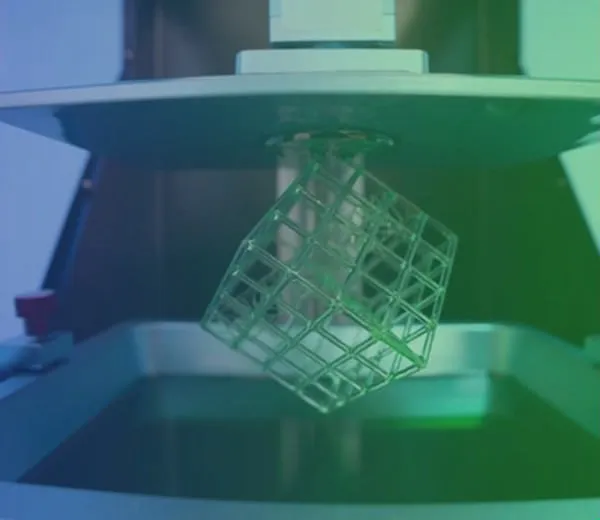

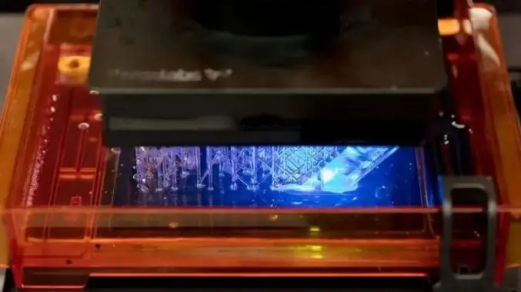

There are various types of 3D printers, each with its unique features. Fused Deposition Modeling (FDM) is widely used for manufacturing prototypes and models with plastic. Stereolithography (SLA) is suitable for intricate details and uses an ultraviolet laser. Digital Light Processing (DLP) is one of the oldest forms and uses lamps for faster printing. Continuous Liquid Interface Production (CLIP) is a faster process that utilizes Vat Photopolymerisation and Digital Light Synthesis technology. Material Jetting applies droplets of material layer by layer and is hardened by UV light. Binder Jetting uses a powder base material and a liquid binder.

Fused Deposition Modeling (FDM), also known as Fused Filament Fabrication (FFF), unwinds a plastic filament through a heated nozzle. Selective Laser Sintering (SLS) is a form of Powder Bed Fusion that fuses powder particles with a high-power laser. Multi-Jet Fusion (MJF) is another form of Powder Bed Fusion that uses a sweeping arm and an inkjet-equipped arm. Direct Metal Laser Sintering (DMLS) uses the same process as metal powder. Sheet Lamination binds material in sheets through external force and welding. Directed Energy Deposition is common in the metal industry and uses a 3D printing apparatus attached to a multi-axis robotic arm with a nozzle for applying metal powder, which is then melted to form a solid object.

3D printing has a wide range of applications. In prototyping, it is exceptionally useful due to its speed and low setup costs, allowing for fast production of parts with great unit economics. For printing production parts, its design freedom and customization capabilities are exploited. In aerospace and aviation, it helps create strong, lightweight parts, including jigs, fixtures, and detailed prototypes.

Various 3D printing technologies are used. 3D printing is also beneficial in industrial machinery, where it is used for prototyping, low-volume production, and creating specialized jigs and fixtures. In consumer electronics, it is used for creating prototypes and durable housings. In the medical field, 3D printing used for surgical guides, implants, prosthetics, and patient-specific replicas is normal. The automotive industry uses 3D printing for testing, jigs, and complex parts. 3D printing is also used in jewelry making, allowing for highly customizable designs.

Here are some tips for successful 3D printing. Firstly, choose the right print settings by adjusting parameters like layer height, print speed, and infill density to optimize print quality and strength. Secondly, ensure proper bed adhesion by keeping the print bed clean and level, and using adhesion aids if needed. Thirdly, support structures are important for objects with overhangs or complex geometries, and most slicing software can generate them automatically. Fourthly, consider the print orientation to find the best balance between strength and aesthetics. Lastly, practice good filament management by storing filaments properly in airtight containers with desiccant packs to prevent moisture absorption and maintain their quality. By following these tips, you can improve the success rate of your 3D prints.

Our local 3D printing shops adhere to the GB 1804-2000 standard, applying and inspecting with a coarse accuracy level (Class C) for linear dimensions that are printed without specified tolerances. For shape and position dimensions not noted tolerance, we follow the GB 1804-2000 L level for implementation and testing. Please refer to the following table:

Basic Size | |

Linear Dimensions | ±0.2 to ±4 mm |

Fillet Radius and Chamfer Height Dimensions | ± 0.4 to ± 4 mm |

Angular Dimensions | ±1°30' to ±10' |

Basic Length | |

Straightness and Flatness | 0.1 to 1.6 mm |

Verticality Tolerance | 0.5 to 2 mm |

The Degree of Symmetry | 0.6 to 2 mm |

Circular Runout Tolerance | 0.5 mm |

3D printed tooling for molds is a process that utilizes 3D printing technology to create molds, jigs, and fixtures for production. It is ideal for making complex shapes that are hard to produce with traditional methods. To create 3D printing molds, a 3D CAD model of the part is made first. This model is then converted into a G-code, which the 3D printer can read. The G-code file is sent to the printer to print the mold. Once the 3D printed mold is ready, it is tested and used in production by filling it with materials like plastic and metal. As the material cools and hardens, it takes the shape of the mold. This 3D printing process is faster and more effective than traditional mold making methods that use CNC machining or manual fabrication. It also allows for more customization and eliminates the need for expensive machining processes to make tooling components.

Richconn is a leading company in the field of 3D printing. We provide custom 3D model printing services to meet diverse needs. We can deliver high-quality 3D prints within days, whether it's a single prototype or thousands of parts, ensuring they align with the specific requirements of our clients' projects.

We offer an online quotation platform. For concept models, our 3D printed injection molds streamline the iterative process, reducing costs and time, and facilitating faster design revisions and prototyping.

In the rapid 3d printing prototyping stage, 3D printing quickly creates new iterations and multiple functional prototypes, addressing challenges in prototype development and ensuring smoother project execution.

Our on-demand production allows clients to 3D print as needed. We use advanced 3D printers that can handle larger batch sizes and various materials beyond polymers, efficiently handling inventory management and production scalability issues.

3D printing uses various materials to create objects. It has advantages like affordability, speed, and using specialized materials. Different processes and techniques are used in different applications. Tips for successful 3D printing include print settings, bed adhesion, support structures, print orientation, and filament management. Richconn provides excellent custom 3D printing services, delivering high-quality prints quickly and offering an online quotation platform. Their 3D printed injection molds streamline the iterative process, and on-demand production handles inventory and scalability.

Why is Titanium Alloy a Difficult Material to Process?October 23, 2023Why do we think titanium alloy is a kind of difficult to machine material? Because of the lack of deep understanding of the processing mechanism and phenomena. However, the material characteristics of titanium alloys make it a challenge for many precision machine shop, and many engineers are searching for suitable solutions for this material. At Richconn, we have a wealth of experience in titanium CNC machining, choose our titanium CNC machining service, we can do it to your satisfaction.view

Why is Titanium Alloy a Difficult Material to Process?October 23, 2023Why do we think titanium alloy is a kind of difficult to machine material? Because of the lack of deep understanding of the processing mechanism and phenomena. However, the material characteristics of titanium alloys make it a challenge for many precision machine shop, and many engineers are searching for suitable solutions for this material. At Richconn, we have a wealth of experience in titanium CNC machining, choose our titanium CNC machining service, we can do it to your satisfaction.view Four Requirements for Medical Component ProcessingMay 22, 2023For CNC machining of parts with multiple and complex surfaces, the sequence of CNC machining, heat treatment, and auxiliary processes should be arranged reasonably, and the connection between processe...view

Four Requirements for Medical Component ProcessingMay 22, 2023For CNC machining of parts with multiple and complex surfaces, the sequence of CNC machining, heat treatment, and auxiliary processes should be arranged reasonably, and the connection between processe...view The Role of CNC Automotive Parts in Automotive IndustryJune 17, 2024CNC machining is often used for complex designs, small products and parts. With CNC machine tools, a wide range of parts can be processed more accurately.With the rapid development of the automotive i...view

The Role of CNC Automotive Parts in Automotive IndustryJune 17, 2024CNC machining is often used for complex designs, small products and parts. With CNC machine tools, a wide range of parts can be processed more accurately.With the rapid development of the automotive i...view All About CNC Production Machining: Types, Benefits, ApplicationsJuly 11, 2024Enhance your understanding of CNC production machining with our comprehensive insights. Discover the world of CNC production machining: its types, benefits, and must-know points for outsourcing.view

All About CNC Production Machining: Types, Benefits, ApplicationsJuly 11, 2024Enhance your understanding of CNC production machining with our comprehensive insights. Discover the world of CNC production machining: its types, benefits, and must-know points for outsourcing.view Key Points in Precision Mold Processing TechnologyJuly 21, 2023Precision mold making is a crucial process that requires specialized skills, knowledge, and tools. It involves the creation of tools that are used to produce other parts or products. The quality of th...view

Key Points in Precision Mold Processing TechnologyJuly 21, 2023Precision mold making is a crucial process that requires specialized skills, knowledge, and tools. It involves the creation of tools that are used to produce other parts or products. The quality of th...view What is Metal Machining?November 3, 2023When it comes to shaping the world around us, few processes play as pivotal a role as metal machining. Whether you're a curious enthusiast or an industry professional seeking deeper insights, this article is your ultimate guide to understanding the essence of metal machining.view

What is Metal Machining?November 3, 2023When it comes to shaping the world around us, few processes play as pivotal a role as metal machining. Whether you're a curious enthusiast or an industry professional seeking deeper insights, this article is your ultimate guide to understanding the essence of metal machining.view

EN

EN

ru

ru