Steel is one of the most widely used materials in the world, thanks to its strength, durability, and versatility. However, not all steel grades are the same. Depending on the chemical composition and the heat treatment, different steel grades can have different properties and applications. One of the most popular and useful steel grades is 4140 steel.

4140 steel is a low alloy steel that contains chromium, molybdenum, and manganese. These elements give 4140 steel some advantages over other types of steel, such as higher hardenability, better toughness, and more resistance to wear and corrosion. 4140 steel is also easy to machine and weld, making it a common choice for many industries.

4140 steel has a high fatigue strength, which means it can withstand repeated stress and strain without breaking. It also has a high torsional strength, which means it can resist twisting and bending forces. Moreover, 4140 steel has a high impact strength, which means it can absorb shocks and impacts without cracking or deforming. These characteristics make 4140 steel ideal for applications that require high performance and reliability.

The chemical composition of 4140 steel is shown in the table below. The percentages of carbon, manganese, silicon, chromium, and molybdenum are the main factors that determine the properties of 4140 steel. The carbon content affects the strength and hardenability of the steel, while the manganese and silicon improve the toughness and ductility. The chromium and molybdenum increase the resistance to high temperature, oxidation, and wear.

| Element | Percentage |

|---|---|

| Carbon | 0.38-0.43 |

| Manganese | 0.75-1.00 |

| Silicon | 0.15-0.35 |

| Chromium | 0.80-1.10 |

| Molybdenum | 0.15-0.25 |

| Iron | Balance |

The density of 4140 steel is 7.85 g/cm3, slightly higher than the density of plain carbon steel, which is 7.8 g/cm3.

The hardness and yield strength of 4140 steel depend on the heat treatment process. The heat treatment methods include annealing, normalizing, quenching, and tempering. Annealing is the process of heating the steel to a certain temperature and then slowly cooling it, to reduce the hardness and brittleness, and increase the toughness and ductility. Normalizing is the process of heating the steel to a certain temperature and then rapidly cooling it, to increase the hardness and strength, and reduce the toughness and ductility. Quenching is the process of heating the steel to a certain temperature and then quickly immersing it in water or oil, to form a martensitic structure, which gives the steel the highest hardness and strength. Tempering is the process of heating the steel to a lower temperature than quenching, and then holding it for a period of time, to reduce the internal stress and brittleness, and increase the toughness and ductility.

The table below shows the hardness and yield strength of 4140 steel under different heat treatment conditions. The hardness is measured by the Brinell scale, and the yield strength is the stress at which the steel begins to deform permanently.

| Heat Treatment | Hardness (HB) | Yield Strength (MPa) |

|---|---|---|

| Annealing | 197 | 655 |

| Normalizing | 269 | 855 |

| Quenching | 536 | 1570 |

| Tempering | 321-388 | 930-1080 |

As can be seen from the table, the hardness and yield strength of 4140 steel vary with the heat treatment method. Generally, the higher the hardness, the higher the yield strength, but the lower the toughness. Therefore, choosing the appropriate heat treatment method depends on the different application requirements and conditions.

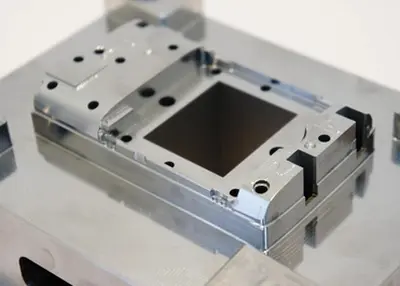

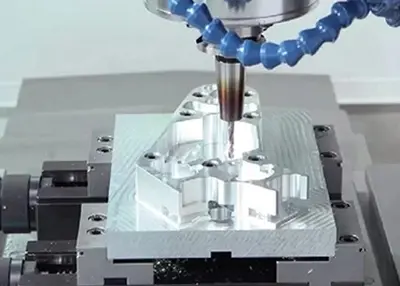

The machinability and weldability of 4140 steel are also related to the heat treatment method. The machinability refers to the performance of the steel in cutting, drilling, milling, and other machining processes. The weldability refers to the performance of the steel in welding, brazing, soldering, and other joining processes. Generally, the machinability and weldability of 4140 steel decrease with the increase of hardness. Therefore, to improve the machinability and weldability of 4140 steel, it is usually necessary to anneal or normalize the steel before machining or welding, to reduce the hardness and strength of the steel. After machining or welding, it is also necessary to quench or temper the steel, to increase the hardness and strength of the steel.

4140 steel is a versatile alloy steel that has a wide range of applications in many industries. The uses of 4140 steel depend on its properties and characteristics, as well as the different working environments and conditions.

Some of the common applications of 4140 steel are as follows:

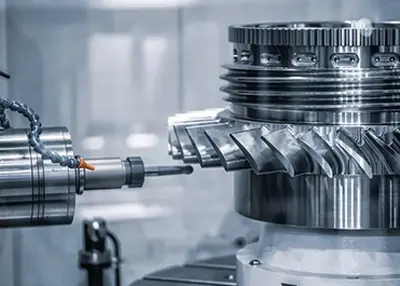

4140 steel is an excellent material for mechanical engineering, as it can be used to manufacture various mechanical parts, such as shafts, gears, couplings, crankshafts, cams, bolts, nuts, pins, springs, etc. 4140 steel has high strength, toughness, wear resistance, and corrosion resistance, which can withstand high loads, speeds, temperatures, and pressures, as well as various frictions, impacts, and vibrations. 4140 steel also has good machinability and weldability, which can be processed by cutting, drilling, milling, grinding, turning, etc., and joined by welding, brazing, soldering, etc., to produce the desired shapes and sizes.

4140 steel is a common material for automotive manufacturing, as it can be used to manufacture various components of automobiles, such as engines, transmissions, differentials, drive shafts, steering systems, suspension systems, braking systems, hubs, tires, etc. 4140 steel has high strength, toughness, wear resistance, and corrosion resistance, which can ensure the performance, safety, durability, and comfort of automobiles. 4140 steel also has good machinability and weldability, which can be processed and joined by various methods, to produce components that meet the standards and specifications of automobiles.

4140 steel is an important material for oil and gas extraction, as it can be used to manufacture oil and gas drilling, transportation, storage, and processing equipment, such as drill rods, drill bits, casings, valves, pumps, pipes, tanks, compressors, etc. 4140 steel has high strength, toughness, wear resistance, and corrosion resistance, which can resist high pressures, temperatures, humidity, salinity, acidity, hydrogen sulfide, and other harsh environmental conditions, as well as various wear, corrosion, cracks, fatigue, and other damages. 4140 steel also has good machinability and weldability, which can be processed and joined by various methods, to produce equipment that meets the requirements and standards of the oil and gas industry.

4140 steel is a high-end material for military and aerospace manufacturing, as it can be used to manufacture various weapons, equipment, aircraft, rockets, satellites, missiles, etc. 4140 steel has high strength, toughness, wear resistance, and corrosion resistance, which can withstand high impacts, explosions, collisions, penetrations, shears, twists, and other forces, as well as high temperatures, pressures, speeds, accelerations, and other conditions, as well as various corrosion, oxidation, combustion, and other phenomena. 4140 steel also has good machinability and weldability, which can be processed and joined by various methods, to produce weapons, equipment, aircraft, rockets, satellites, missiles, etc., that have high precision, performance, reliability, security, and safety.

In this article, we have learned about 4140 steel, a versatile alloy steel that has excellent properties and uses. 4140 steel is a low alloy steel that contains chromium, molybdenum, and manganese, which give it higher hardenability, better toughness, and more resistance to wear and corrosion than other types of steel. 4140 steel is also easy to machine and weld, making it a common choice for many industries.Looking for professional 4140 steel CNC machining services? Choose Richconn, we focus on high-quality 4140 steel processing, provide professional technology and excellent services, and ensure that your processing needs are met.

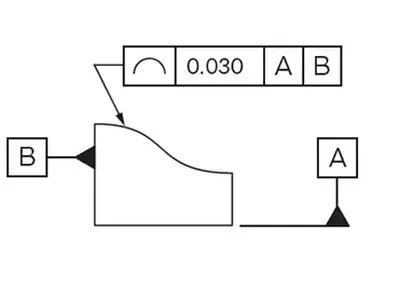

Unveiling the Precision: The Line Profile UnraveledNovember 21, 2023In the vast realm of engineering and manufacturing, the significance of line profiles cannot be overstated. These seemingly simple geometric elements play a pivotal role in ensuring precision, guiding us through the intricacies of design and production.view

Unveiling the Precision: The Line Profile UnraveledNovember 21, 2023In the vast realm of engineering and manufacturing, the significance of line profiles cannot be overstated. These seemingly simple geometric elements play a pivotal role in ensuring precision, guiding us through the intricacies of design and production.view What Is a Shaft?October 30, 2023A shaft is basically a rotating part of any machine, having a circular cross-section, which is used to transmit power from one part to another or from a power generating machine to a power absorbing machine. To transmit power, one end of the shaft is connected to the power source and the other end is connected to the machine. Shafts can be solid or hollow as per requirement, hollow shafts help in reducing weight and provide advantages.view

What Is a Shaft?October 30, 2023A shaft is basically a rotating part of any machine, having a circular cross-section, which is used to transmit power from one part to another or from a power generating machine to a power absorbing machine. To transmit power, one end of the shaft is connected to the power source and the other end is connected to the machine. Shafts can be solid or hollow as per requirement, hollow shafts help in reducing weight and provide advantages.view Aluminium Extrusion: A Versatile and Innovative Manufacturing ProcessNovember 30, 2023Aluminium extrusion is a process of forcing aluminium alloy material through a die to create a continuous shape or product. The material can be solid, liquid, or semi-solid, and it can be metal, plastic, ceramic, or food.view

Aluminium Extrusion: A Versatile and Innovative Manufacturing ProcessNovember 30, 2023Aluminium extrusion is a process of forcing aluminium alloy material through a die to create a continuous shape or product. The material can be solid, liquid, or semi-solid, and it can be metal, plastic, ceramic, or food.view Anodized Aluminum: How Much Do You Know?April 4, 2023Anodized aluminum refers to a layer of dense aluminum oxide plated on the surface of aluminum and aluminum alloy in order to prevent further oxidation, with chemical properties that are the same as th...view

Anodized Aluminum: How Much Do You Know?April 4, 2023Anodized aluminum refers to a layer of dense aluminum oxide plated on the surface of aluminum and aluminum alloy in order to prevent further oxidation, with chemical properties that are the same as th...view Rubber mold customization:know everything about design, material selection and manufacturingDecember 18, 2023Introduction:Custom rubber mold making is a complex process that involves issues such as design, materials, manufacturing, inspection, production, maintenance, and so on. The aim of this article is to...view

Rubber mold customization:know everything about design, material selection and manufacturingDecember 18, 2023Introduction:Custom rubber mold making is a complex process that involves issues such as design, materials, manufacturing, inspection, production, maintenance, and so on. The aim of this article is to...view Five Axis CNC Machining Features and AdvantagesNovember 4, 2022Five-axis machining machines to quickly and efficiently manufacture complex milled parts in small batches from a variety of materials. Using five-axis precision machining is often a more efficient way...view

Five Axis CNC Machining Features and AdvantagesNovember 4, 2022Five-axis machining machines to quickly and efficiently manufacture complex milled parts in small batches from a variety of materials. Using five-axis precision machining is often a more efficient way...view

EN

EN

ru

ru