3D printing is a prevalent and multifunctional technique accompanied by a profusion of applications and advantages. The term is equivalent to additive manufacturing, which serves as an overarching term for all 3D printing types. Additive manufacturing units construct any part one layer by one layer and present a lengthy list of advantages. All the different types of 3D printing techniques enable you to select among material types and obtain the proper combination of surface finish, durability, speed, and cost.

This comprehensive guide will explain different types of 3D printers, the materials they use, and more to help you better choose the right process for your project.

Additive manufacturing refers to all 3D printing approaches, using CAD designs to build forms layer by layer. It's more advanced than traditional technology, which requires removing extra materials. Initially, only specific thermoplastics were suitable for 3D printing, limiting its application. Over time, diverse techniques allow the use of different types of 3D printing filament like metals, ceramics, and organic materials, yet thermoplastics remain popular, with ABS, PLA, PC, and PVA being common in various industries due to their multifunctionality and suitable characteristics.

The types of additive manufacturing can be divided according to what they produce or the type of material they use, but in order to apply the structure to the technology worldwide, the International Standards Organization (ISO) divided them into several general types.

Binding jetting

Binder Jetting is a metal 3D print process that can also do sandstone 3D printing. It deposits a binding agent on powder in a powder bed. It's a hybrid of SLS and material jetting and can create full-color models for sand 3D printing. It's less expensive but less accurate, making it suitable for full-color 3D printing and can produce strong metal parts. Its applications include metal parts, models, and sand-casting molds.

Vat Polymerization

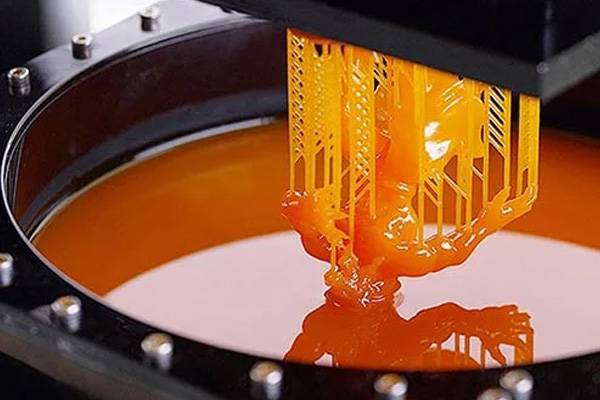

Vat Polymerization is a 3D printing procedure using a light source to solidify photopolymer resin. It has various types and an excellent surface finish, enabling complex geometries. Many other forms are under research, adding to their application and versatility. Its light source differs among types and is integral to the solidification process. It has common applications like injection molds, etc.

Material jetting

Material jetting is a common 3D printing option that uses liquidized material droplets to build layers. It can use various materials on one object to create parts with mixed colors and textures. Photopolymer resin is a feasible material, presenting a detailed and good surface finish but with weak and brittle parts not suitable for mechanical applications. It has applications like aesthetic prototypes and medical models.

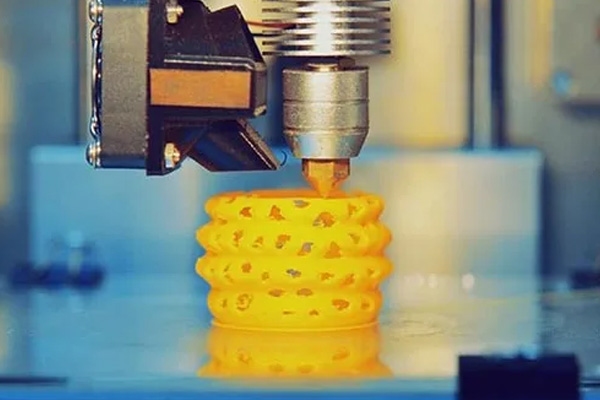

Material Extrusion

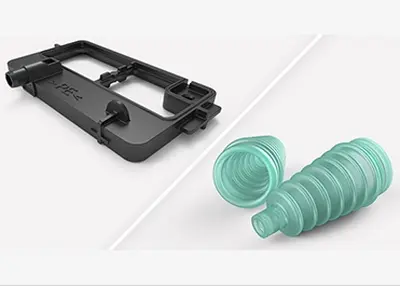

Extrusion is a common industrial process, and the 3D printing technique operates on the same principle. It mostly uses plastics and composite filaments like PLA, ABS, etc. Materials are propelled through a heated nozzle and deposited on a path to form a layer, which is repeated till the part is complete. Material extrusion is the lowest-cost technique with decent accuracy and versatility and is commonly used in domestic 3D printers. Its common applications include electronic housings, form-fitting, fixtures, and investment casting patterns.

Sheet Lamination

Some printers employ paper and plastic as the build material in order to reduce the cost of printing. In this technique, a number of layers of adhesive plastic, paper, or metal laminates are continuously joined together and cut to shape by means of a laser cutter or knife.

The layer resolution can be determined by the material feedstock. Normally, it varies between one and a few sheets of copy paper. This process can be applied to produce large parts, but the dimensional accuracy of the final product will be considerably lower than that of stereolithography.

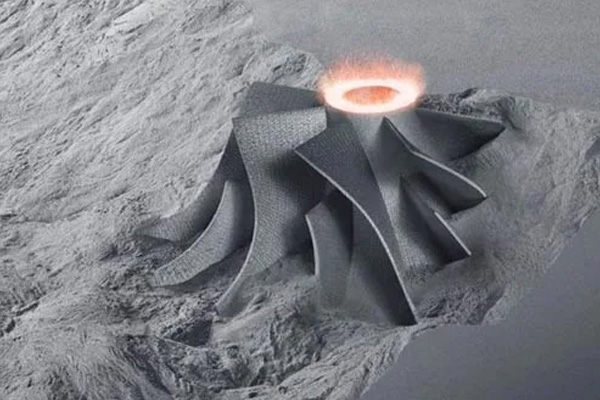

Powder Bed Fusion

This is among the most advanced types of 3D printing with much potential in many high-end apps. Powder bed fusion works by focusing a thermal source on a small area to induce fusion between material layers in powder form. For instance, it operates on most thermoplastics, ceramics, and metals to achieve an excellent dimensional accuracy of 0.3%. Some common 3D printing procs like SLS, SLM, EBM, DMLS, and MJF, etc. are included.For illustration, here are some common applications based on the powder bed fusion technique, such as: functional metal parts,low-volume production,hollow designs.

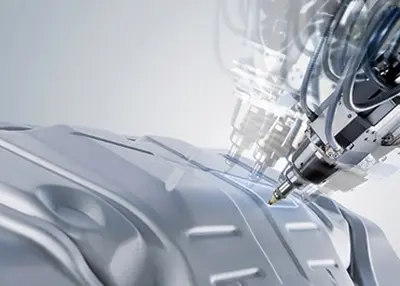

Direct Energy Deposition

The directed energy deposition technique is largely utilized in the high-tech metal industry and rapid manufacturing. This procedure encompasses a printing device that is fitted with a nozzle attached to a multi-axis robotic arm. The metal powder is deposited by the Nozzle onto the build platform, and then it is melted by using a laser, plasma, or electron beam to shape a solid object.

There are different types of 3D printers as well as different types of 3D printer filament. Consumer 3D printers are not restricted to ABS and PLA filaments anymore. The popularity of additive manufacturing technology has brought about the inflow of a lot of engineering plastics. Though ABS and PLA are still popular, many 3D printing enthusiasts have made the switch to newer materials.

Polylactic Acid is like training wheels for 3D printing. It's easy to print with on even the cheapest 3D printers, requiring low print temperatures and maybe not even a heated bed. PLA is good for cosmetic 3D prints, but not for much else. Though it has high tensile strength, it lacks toughness and is brittle and prone to cracking. Its low-temperature printability means poor heat resistance, and it warps in direct sunlight or in-car conditions. PLA's tendency to creep makes it unusable for functional prints that need to bear load or use fasteners. So, once enthusiasts master settings and tuning with PLA, they move to other materials.

PETG, similar to the plastic in bottles and containers, is the second filament to challenge after mastering PLA. It's better than PLA in many aspects and suitable for functional 3D printing. Though more difficult to print, it allows learning crucial concepts. It's hygroscopic and requires drying in humid areas. It's a compromise between PLA and ABS filaments, ideal for impact resistance and functional prints.

TPE consists of a number of plastics possessing rubber-like properties, and it is utilized in applications that require flexibility. The common flexible filaments labeled as TPE are available in diverse shore hardness, which serves as a gauge of flexibility. Indeed, TPE encompasses a wide range of filaments, such as the urethane-based TPU, which is somewhat more rigid to facilitate printability. The copolyester-based variant, TPC, features enhanced resistance to heat, UV, and chemical agents.

ABS, in its injection molded form, can be found in various consumer products, and due to its familiarity, price, and availability, it has become the preferred material for the commercial 3D printing industry. It is a terrific material with a good price-to-performance ratio and heat resistance. ABS has good tensile strength and toughness, making it ideal for functional prints and some engineering applications. It can be used in high-temperature applications like 3D printer hot-end components and car interiors. Any engineering scenario requiring resistance to heat, impact, and wear can be met economically with ABS.

ASA is a modified version of ABS, which is simpler to print and has enhanced UV resistance. Large ASA prints are more manageable as they are less prone to warping compared to ABS. Also, most ASA filaments produce fewer VOCs during printing. ASA can be applied in the same ways as ABS, and it additionally offers the flexibility to maintain durability and color integrity even under heavy exposure to sunlight.

Polyamide, also commonly referred to as Nylon, can be found in consumer durables such as gears, hinges, and sliding components - essentially in any application that demands extreme wear resistance, low friction, excellent toughness, and a certain degree of temperature tolerance. PA is essential in the powder-sintered 3D printing processes utilized in commercial SLS 3D printers.

PC serves as one of the most robust 3D printing filaments that can be accessed by consumer 3D printers. May you ask how robust it is? Well, this particular material is employed in the manufacture of everything ranging from bullet-proof glass to fighter jet canopies. PC is capable of withstanding temperatures as high as 110 °C, and some blends even go beyond that astonishing figure.

The three typical 3D printers for plastic parts are SLA, SLS, and FDM. Formlabs provides two professional printing technologies, SLA and SLS, making these powerful and accessible industrial fabrication tools available to professionals worldwide.

Stereolithography, invented in the 1980s, is one of the popular 3D printing technologies for professionals. SLA 3D printers use a laser to cure liquid resin into hardened plastic. They are popular for producing high-accuracy, watertight prototypes and parts in advanced materials. Resin 3D printing is a good choice for detailed prototypes with smooth surfaces and is widely used in various industries. It is ideal for rapid prototyping, functional prototyping, concept modeling, short-run production, dental applications, and jewelry prototyping and casting.

Selective laser sintering (SLS) 3D printers use a laser to sinter polymer powder into a solid structure. It doesn't require dedicated support structures, making it suitable for complex geometries. Parts produced have excellent mechanical characteristics. The common material is nylon, which has good properties. The low cost, high productivity, and established materials make SLS popular for functional prototyping, end-use parts, and limited-run or bridge manufacturing.

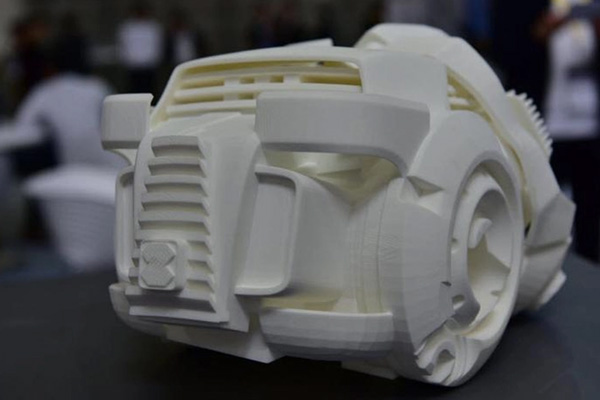

Fused deposition modeling (FDM), also known as FFF, is the most widely used at the consumer level. FDM 3D printers extrude thermoplastic filaments through a heated nozzle to build layers on a platform. It's suitable for basic models and simple prototyping. However, it has low resolution and accuracy, and chemical and mechanical polishing is needed for a higher-quality finish. Industrial FDM printers use soluble supports and offer more thermoplastics but at a high price. It's ideal for basic models and simple prototyping.

As you can see, 3D printing serves as the optimal solution for product developers to produce multiple design iterations within a short period. Richconn presents swift manufacturing processes for 3D prints, enabling the efficient and cost-effective creation of prototypes. The rapid prototyping accelerates the product development cycle. The high precision and consistency of 3D printed components make it the finest means to craft intricate production parts without expensive tooling.

As one of the best 3D printing manufacturers, Richconn stands out by offering a broad array of materials and approaches for 3D printing. You can select appropriate types of filament for 3D printing for your particular application, irrespective of whether it is for prototyping, functional parts, or end-use products.

Complete List of Machined Hardware Product TypesOctober 19, 2023Hardware: traditional hardware products, also known as "small hardware". Refers to gold, silver, copper, iron, tin five kinds of metal. Artificial processing can be made into knives, swords and other works of art or metal devices. In modern society, hardware is more extensive, such as hardware tools, hardware parts, daily-use hardware, construction hardware and security products. Most of the small hardware products are not final consumer goods.view

Complete List of Machined Hardware Product TypesOctober 19, 2023Hardware: traditional hardware products, also known as "small hardware". Refers to gold, silver, copper, iron, tin five kinds of metal. Artificial processing can be made into knives, swords and other works of art or metal devices. In modern society, hardware is more extensive, such as hardware tools, hardware parts, daily-use hardware, construction hardware and security products. Most of the small hardware products are not final consumer goods.view Five Axis CNC Machine Tool: Precision Machining of Carbon Fiber Composite MaterialsMay 22, 2023Further CNC cutting and drilling of raw carbon fiber parts is necessary to meet the precision requirements or assembly needs. According to new material introductions, carbon fiber reinforced composite...view

Five Axis CNC Machine Tool: Precision Machining of Carbon Fiber Composite MaterialsMay 22, 2023Further CNC cutting and drilling of raw carbon fiber parts is necessary to meet the precision requirements or assembly needs. According to new material introductions, carbon fiber reinforced composite...view The Functional Advantages of Custom PVD Coating in Automotive DesignJanuary 5, 2024When it comes to automotive design, every detail matters. From the sleek lines of the exterior to the carefully crafted interior, each element plays a crucial role in creating a unique and memorable d...view

The Functional Advantages of Custom PVD Coating in Automotive DesignJanuary 5, 2024When it comes to automotive design, every detail matters. From the sleek lines of the exterior to the carefully crafted interior, each element plays a crucial role in creating a unique and memorable d...view DESIGN TIP: Thermoplastics and Thermosets in ComparisonOctober 18, 2023There are two main categories of plastic materials: thermoplastics and thermosets, which differ in their behavior under heat. In this design tip, we present a few considerations to keep in mind when using these materials.view

DESIGN TIP: Thermoplastics and Thermosets in ComparisonOctober 18, 2023There are two main categories of plastic materials: thermoplastics and thermosets, which differ in their behavior under heat. In this design tip, we present a few considerations to keep in mind when using these materials.view Engineers Must Read: The Art of Wire Cutting and Complementary ProcessingAugust 24, 2023Introduction:In the world of engineers, the collision of creativity and technology is always fascinating. This article will explore an intriguing topic that is a must-read for engineers: the art of wi...view

Engineers Must Read: The Art of Wire Cutting and Complementary ProcessingAugust 24, 2023Introduction:In the world of engineers, the collision of creativity and technology is always fascinating. This article will explore an intriguing topic that is a must-read for engineers: the art of wi...view What is CNC Milling Machine: Definition, Uses, Types & PricesMarch 29, 2024Let's delve deeper into CNC milling machine, which holds significant importance for your project, and explore the mill machine in detail.view

What is CNC Milling Machine: Definition, Uses, Types & PricesMarch 29, 2024Let's delve deeper into CNC milling machine, which holds significant importance for your project, and explore the mill machine in detail.view