CNC machining, which makes use of cutting-edge technology to precisely cut, shape, and create items, is a significant component of contemporary production. You should be well-versed in CNC machining if you wish to comprehend its significance in the manufacturing process. The fundamentals of CNC machines' operation and their use in the production of everything from car parts to electronic devices will be discussed here. We will also discuss the significance of this technology and the various sectors that depend on it. Read on!

The earliest numerically controlled (NC) machines were created in the 1940s, which is when CNC machining initially began. Older NC devices, however, still had limited functionality and required manual input. The first CNC machining tool wasn't developed until the 1970s when the industry underwent a transformation brought about by the arrival of computers. The advanced computer controls installed in it enabled the CNC operator to enter commands directly into the machine, which then carried out the necessary operations automatically. This greatly simplified the manufacturing process, in addition to processing data at high speeds and high accuracy. These devices have grown in sophistication and prevalence over time.

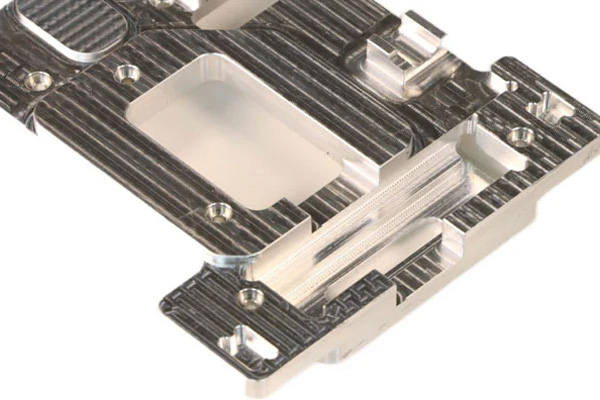

So, what does CNC stand for in machining? It stands for “computer numerical control”, which means the machine is run by a computer and it has already grown in importance within the industrial sector. This reflects the combination of ongoing advancements in technology, the creation of CNC machine tools, the creation of sophisticated software and hardware, and the introduction of new materials and equipment. It is computer-controlled; CNC software regulates the cutting tool's movement to remove material from the workpiece, enabling the production of a range of CNC machining parts, including those composed of metal, plastic, and other materials. Unlike traditional processes, this process also allows for the production of parts with complex geometries and high levels of CNC precision machining, making it popular for applications in a wide range of industries, including aerospace, automotive, medical devices, and consumer products.

With the rapid development of technology, different types of CNC machining services come to satisfy different needs. Understanding their typical types contributes to selecting the most suitable equipment for specific manufacturing requirements, whether it involves cutting, shaping, engraving, or additive manufacturing processes.

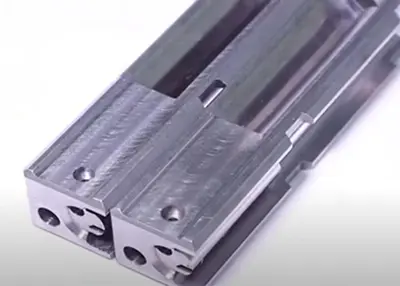

CNC Milling: Used for cutting and drilling operations, these machines can move in multiple axes to create complex shapes.

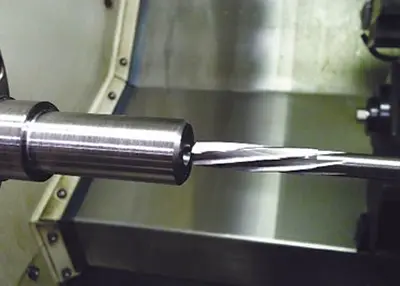

CNC Lathes: Ideal for turning and shaping cylindrical parts by rotating the workpiece while cutting tools remove material.

CNC Plasma Cutters: Employed for cutting metal sheets using a plasma torch controlled by CNC technology.

CNC Laser Cutting: Utilized for precise cutting of materials using a laser beam guided by computer control.

CNC Routers: Commonly used in woodworking and metalworking to cut, carve, and engrave materials with precision.

CNC 3D Printing: Additive manufacturing machines that build 3D objects layer by layer using various materials like plastics, metals, and ceramics.

Moreover, if you want to enhance the functionality, aesthetics, and performance of machined parts, you'd better master the common CNC materials and surface finishes, which helps in selecting the appropriate materials for machining projects.

Here’s a list of common CNC machining. materials:

Aluminum: Lightweight and versatile, commonly used in aerospace, automotive, and general engineering applications.

Steel: Durable and strong, ideal for industrial components, machine parts, and structural elements.

Titanium: Known for its high strength-to-weight ratio, used in aerospace, medical implants, and high-performance applications.

Brass and Copper: Used for decorative parts, electrical components, plumbing fittings, and precision instruments.

Plastics: Including ABS, acrylic, nylon, and polycarbonate, suitable for various consumer products, prototypes, and industrial parts.

Exotic Alloys: Such as Inconel, Hastelloy, and Monel, known for their exceptional heat resistance and corrosion properties, often used in extreme environments.

Here’s a list of common surface finishes:

Anodizing: Enhances corrosion resistance and adds color to aluminum parts through an electrolytic process.

Powder Coating: Durable finish applied electrostatically and cured under heat for a smooth, protective coating in various colors.

Polishing: Creates a smooth, reflective surface by buffing and polishing the material to remove imperfections.

Painting: Applied in various colors and finishes to provide protection, aesthetics, and branding on machined parts.

Plating: Electroplating processes like chrome, nickel, or gold plating to improve durability, corrosion resistance, and appearance.

Bead Blasting: Uses fine glass beads to achieve a uniform matte finish on metal parts for a clean and textured surface.

This part will provide a comprehensive view of its pros and cons to help you optimize production strategies and maximize the benefits of this advanced manufacturing technology. The following are the primary benefits and drawbacks of CNC machining:

Benefits | Drawbacks |

It makes it possible to precisely control the cutting tool, producing products with exceptional repeatability and tight tolerances. | The CNC machining cost is high. Furthermore, they come in a variety of forms, and the majority of their functions are not interchangeable. so for small and medium-sized enterprises, capital requirements are important. |

Its high operating rates allow parts to be produced more quickly.

| Operators must be trained: CNC operators must undergo extensive training before they can begin operating, in contrast to traditional machinery. It implies that their wage requirements are higher and they are in greater demand. |

Consistent quality is guaranteed, which is great for consumer goods or high-volume manufacturing. | Even though they are efficient, some CNC processes could waste more material than manual ones. But in many instances, the accuracy, consistency, and efficiency they provide might outweigh this drawback. |

It provides the versatility to produce a broad range of parts, from straightforward to complex designs, using efficient programming and the appropriate machining strategy. | |

Consistent quality is guaranteed, which is great for customers or high-volume production. | |

Because it uses economies of scale to reduce the cost per piece and satisfies industry demands for affordability and efficiency, it is economical for big production runs.

| |

When compared to manual procedures, it provides increased safety because operators may remotely control the devices, lowering their exposure to potential threats like heat and sharp objects. | |

Since the majority of the operations are automatic, they are designed to operate reliably on their own without human input, reducing the total amount of maintenance needed. |

Modern CNC systems aim to reduce human intervention as much as they can. This guarantees steady and uninterrupted functioning, which promotes intelligent production and yields superior outcomes.

On the other hand, CNC manufacturing necessitates meticulous thought from the first design to the last fabrication. Three distinct steps make up the complete process:

l Design

With CNC machining, using software programs like CAD, CAM, and CAE is an essential first step. These tools are used by engineers and designers to create goods and parts like CNC machining aerospace parts and then determine whether or not they can be manufactured. This evaluation, referred to as Design for Manufacturing (DFM), is essential. It guarantees that the design is tailored to work within the limitations of current technology while maximizing efficiency and minimizing expenses.

Pre-processing and programming are made easier by the internal CAM tool that is typically included with CAD solutions on the market.

The designer transfers the finished CAD design into a file format that is suitable for CNC machines, usually STEP or IGES.

Programming and Pre-processing

G-codes and M-codes are the main codes used in CNC machine programming to interface with machines. The cutting tool's path in CNC operations is guided by these codes, which are produced by CAM packages.

When a design follows DFM (Design for Manufacturing) guidelines, CNC machinists typically don't have to get involved in the pre-processing or operating stages. To ensure optimal performance, however, a certain amount of manual intervention can be necessary if the design doesn't live up to these guidelines.

In CNC machining, pre-processing is a required step whose length is determined by the caliber of the design. It only takes a few minutes to program the G-Codes or M-Codes. However, the design's adherence to DFM norms is critical to the success of CNC programming. Precise designs yield accurate codes and satisfactory results; imperfect designs result in incorrect codes and subpar results.

Machining

The machining procedure is the last phase, where extra material is removed from a block using the codes that were supplied in the preceding step.

Although perfect replicability of CAD model dimensions is generally difficult, precision is essential in machine tooling. That's why, according to industry standards, machinists usually use standard ISO 2768 tolerances. It's common knowledge that higher manufacturing costs are a result of tighter tolerances.

Machining procedures are widely used in many different fields and are renowned for their accuracy in producing CNC parts. The following sectors most greatly profit from CNC machining's capabilities:

Industry | Applicants |

Medical Devices | Surgical devices, prostheses, and implants |

Automotive | Components for the engine, transmission, and suspension |

Prototyping and R&D | For research and development, create test pieces and prototypes |

Aerospace | Ammunition and other such goods |

Consumer Products | Toys, electronics, and everyday home goods |

Jewelry Production | Exquisite jewelry demands consistency and accuracy |

Machinery and Equipment | Gears, pumps, and valves |

Models and Dies | Dies and molds required to produce metal and plastic goods |

Then, let's come to the part about the quality standards of superior CNC machining! This knowledge enables informed decisions that drive operational excellence and competitiveness in your CNC projects.

1. High precision: By guaranteeing that the components' size and shape accuracy satisfies the specifications, high precision CNC machine tools can lower the number of errors made during further processing and assembly, enhancing the quality of the final product.

2. High efficiency: CNC machine tools have the ability to execute several processing steps automatically, which significantly increases processing effectiveness and reduces the length of the production cycle.

3. High level of automation: CNC machines use automation control technology to finish the machining process automatically, minimizing the need for human intervention and enhancing both the efficiency and safety of production.

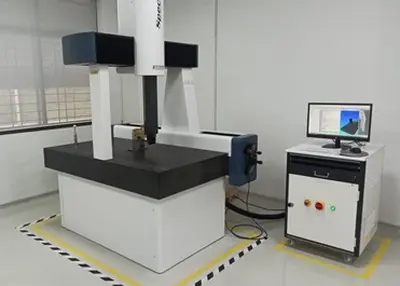

4. Intelligent control system: Typically found in high-quality CNC machine tools, intelligent control systems provide automated control, real-time monitoring, problem detection, and other features that boost stability and productivity.

5. High-efficiency cooling system: High-quality CNC machine tools typically have this feature, which can swiftly remove heat, keep the tool and machine tool operating steadily, and enhance the quality and efficiency of the machining.

6. Flexible production: CNC machine tools have a high degree of production flexibility, can be swiftly adjusted to changes in the market, and can be tailored to produce a variety of parts with different types and requirements.

7. Good machining quality: CNC machine tools provide a consistent and dependable machining quality that can guarantee that parts' dimensions, shapes, and surfaces are up to standard, enhancing the dependability and quality of the final output.

In a word, high accuracy, high efficiency, flexible production, high automation, high-efficiency cooling system, good machining quality, and intelligent control system are the hallmarks of high-quality CNC machine tool processing. These characteristics can lower production costs, increase product quality and efficiency, and boost an organization's ability to compete.

It might be resource-intensive and require CNC certification and experience in machining parts to meet the needs of small and medium-sized businesses in particular when it comes to CNC production. It is now standard procedure in the industry to collaborate with a specialist CNC machining supplier like Richconn in order to address these issues.

Are you asking yourself, "Is there any CNC machining near me?" or "custom CNC machining near me?" You should work with Richconn as your perfect manufacturing partner. In addition to prototype CNC machining, aerospace CNC machining, custom CNC machining, online CNC machining, and other CNC machining services, we can offer the best CNC machining and precision CNC machining services. The company has a track record of success and operates in China, the core of the world's manufacturing.

Furthermore, Richconn has cutting-edge quality control procedures in place in addition to its ISO 9001 certification, guaranteeing that every project satisfies the highest levels of client satisfaction. It is a dependable option for a variety of CNC machining needs because of its experience and commitment to quality control.

The foundation of contemporary industry, CNC machining has aroused interest both inside and outside of the sector. It has been a major force behind the industrial revolution and will continue to be so.

The capabilities of CNC machining are critical to the development of Industry 4.0 and the smart factory. With this technology, unmatched precision and consistency are guaranteed by bridging the gap between manual machining and digital control. Although this manufacturing process has certain drawbacks, they are greatly outweighed by the advantages. It is anticipated that the existing issues will be resolved as technology advances, hence enhancing its influence.

Would you like to witness the effects of top-notch CNC machining? Reach out to Richconn right now to discover more about the superiority of cutting-edge CNC solutions!

Unveiling the Precision World of Machined Gears: A Richconn PerspectiveNovember 10, 2023In the intricate tapestry of mechanical engineering, machined gears stand as the unsung heroes, translating rotational motion with unparalleled precision. These gears are meticulously crafted to meet the demanding requirements of various industries, ensuring seamless operation in complex machinery.view

Unveiling the Precision World of Machined Gears: A Richconn PerspectiveNovember 10, 2023In the intricate tapestry of mechanical engineering, machined gears stand as the unsung heroes, translating rotational motion with unparalleled precision. These gears are meticulously crafted to meet the demanding requirements of various industries, ensuring seamless operation in complex machinery.view Nine Methods Of Metal Surface Treatment ProcessJune 21, 2022Metal surface treatmentIn order to improve the appearance, texture, function and other properties of metal surface treatment products, it is usually necessary to treat the metal surface. The so-called...view

Nine Methods Of Metal Surface Treatment ProcessJune 21, 2022Metal surface treatmentIn order to improve the appearance, texture, function and other properties of metal surface treatment products, it is usually necessary to treat the metal surface. The so-called...view What Is Reaming & Reamer And Their DifferencesSeptember 26, 2023Reaming is an important process in CNC machining services, and its main purpose is to join parts or components so that they can rotate or oscillate relative to each other and move at a specific angle or direction.view

What Is Reaming & Reamer And Their DifferencesSeptember 26, 2023Reaming is an important process in CNC machining services, and its main purpose is to join parts or components so that they can rotate or oscillate relative to each other and move at a specific angle or direction.view What Industries Use Stainless Steel?October 27, 2023Stainless steel is the abbreviation of stainless and acid-resistant steel, air, steam, water and other weak corrosive media or with stainless steel is called stainless steel, and will be resistant to chemical corrosive media (acids, alkalis, salts and other chemical corrosion) corrosion of the steel is called acid-resistant steel.view

What Industries Use Stainless Steel?October 27, 2023Stainless steel is the abbreviation of stainless and acid-resistant steel, air, steam, water and other weak corrosive media or with stainless steel is called stainless steel, and will be resistant to chemical corrosive media (acids, alkalis, salts and other chemical corrosion) corrosion of the steel is called acid-resistant steel.view Chip Types Of Automatic Gear Production Line And Application Scope Of Chip Treatment SystemApril 12, 2022This paper studies the characteristics of different kinds of chips produced in the process of gear machining and gives the corresponding treatment scheme, which provides technical support for the auto...view

Chip Types Of Automatic Gear Production Line And Application Scope Of Chip Treatment SystemApril 12, 2022This paper studies the characteristics of different kinds of chips produced in the process of gear machining and gives the corresponding treatment scheme, which provides technical support for the auto...view What Is a CMM Machine: Components, Uses, and BenefitsMarch 15, 2024Here is a thorough introduction to CMM machines from components, uses to benefits. Let’s have a deeper look and choose the best CMM service for your projects.view

What Is a CMM Machine: Components, Uses, and BenefitsMarch 15, 2024Here is a thorough introduction to CMM machines from components, uses to benefits. Let’s have a deeper look and choose the best CMM service for your projects.view