Chrome plating must be familiar to you. A tiny layer of chromium applied to a metal surface will make the object sparkle and shine. However, applying a chrome finish to surfaces isn't always the solution. It is occasionally necessary to know how to remove chrome plate. It's not a stroll in the park, we must admit. But Here are some methods for removing chrome plating that you might try out.

Let's take a quick look at electroplating before we respond. The process of electroplating involves covering another type of metal with a layer of metal on the surface. In order to provide corrosion protection, extend the life of the product, and even enhance the aesthetics of metal surfaces, a less corrosive or noncorrosive metal is utilized to coat a more corrosive metal.

Let's return to the matter at hand: what is chrome plating? Now that we have cleared things up. The process of electroplating a thin layer of chromium onto a metal object is known as "chrome electroplating." Chromium plating is another term for this type of plating. Chrome is the end result of chrome plating.

It gives things the appearance of a silvery, glossy covering. Many substances can produce dazzling finishes that are comparable to polished aluminum, but chrome plating typically takes on a brighter, more mirror-like appearance that results in reflections that are more accurate.

Chrome plating mainly comes in two varieties: ornamental and hard. Let’s have a deep look!

Hard Chrome

Another name for this is industrial chrome. For materials that must be extremely strong and practical, this type of plating—which is thicker than decorative plating—is applied. Hard chrome coating's high lubricity and hardness make it beneficial for lowering friction. This kind of coating makes materials more resilient to abrasion from wear and tear in addition to reducing friction due to its lubricity and hardness. Hard chrome typically has a thickness of 0.02 to 0.04 mm. Expanding chemical inertness, particularly oxidation resistance, is another amazing feature of hard chrome plating.

Decorative Chrome

Bright plating is another term for this kind of chrome plating. To be honest, the name alone probably gives a lot away! The normal chrome coat in decorative chrome plating is much thinner. Usually, it is only used for materials with a high potential for aesthetics.

That being said, strong chrome plating is a better option for protecting the material from corrosion and abrasion than this type of coating. The thickness of the chrome coat, incidentally, is the main distinction between them. 0.002 mm to 0.02 mm is the typical thickness range for decorative chrome plating.

Depending on the kind of material and its intended use, chrome coating has a variety of uses. A decorative chrome coating is required for materials that have a great potential for visual appeal. Thick materials, such as those with a strong chromium finish, are needed for more technical and functional applications. The different real-world uses for chrome plating in the modern industry are listed below.

In the automotive sector, chromium which is both attractive and hard is useful. You may ask “Is there any hard chrome plating near me?” Definitely yes! Hard chrome is ideal for some engineering components, such as shock absorbers, which require strength and longevity due to the prolonged hard work they undergo.

Chromium coatings are starting to be employed extensively in the car industry. Automotive parts with chromium coatings have better resistance to corrosion and wear, a longer service life, and lower maintenance costs. For example, chrome plating rims have won the favor of the market with their unique charm because of chrome plating for wheels

However, decorative chrome can be used for sections like exhaust pipes, body parts, rims, and other pieces where aesthetics are important.

One effective filler material to guarantee that some worn-out materials regain their original proportions is hard chrome plating.

Kitchen faucets and kitchenware are frequently plated with decorative chrome.

An essential coating for parts of aircraft, jets, and other flying bodies is hard chrome plating. It keeps the different parts resistant to deterioration and makes sure they don't weigh too much while extending their lifespan.

As previously mentioned, electroplating is the process of electrically depositing a layer of metal on another metal surface. Chrome plating is one type of electroplating. This procedure requires an electrical charge since it uses an electroplating approach.

In essence, a chromium anhydride container is charged electrically by the manufacturer. The chemical reactions required to deposit the chromium metal on the surface of the substance the producer wishes to plate with chrome are brought about by this charge. Clearly, this oversimplifies the actual procedures required for chrome plating.

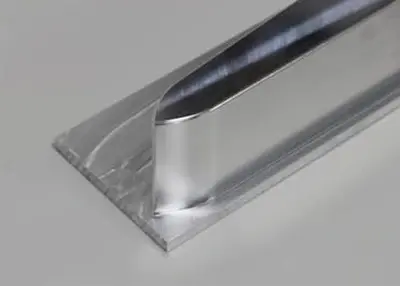

Furthermore, by creating a multi-layer structure on the metal surface, triple chrome plating, an advanced chrome plating technique, greatly increases the hardness and wear resistance of the chrome layer. Applying a coating of chromium metal to the substrate's surface creates a dense layer of chrome; heat treatment is necessary to enhance the plated layer's characteristics once chrome plating is finished. To further increase the plated layer's resistance to wear and corrosion, the crystal structure and microhardness can be changed with the right heat treatment. To guarantee the integrity and quality of the plated layer, cleaning and inspection are the last steps in the post-treatment stage.

In general, chromium plating prevents corrosion and increases the durability of metals that are coated with it. Nevertheless, prolonged use-related wear and tear could harm the chromium coat, just like it would most other surface treatments. It is therefore crucial to think about how to remove chrome plating from plastics and how to remove the chrome coat from metals.

1. Specialized Machinery

Certain materials can be stripped of their chrome with the aid of specialist machinery. The fact that these machines may be used for both metal and plastic is one of its benefits. a feature that is not available when chemical solutions are used by the manufacturer.

Using an Abrasive Blaster

Abrasive blasting, also referred to as sandblasting, is a process that uses a fine-powder spray to abrade chrome materials. An abrasive blaster is a tool used in abrasive blasting. Due to their ability to totally remove chrome plating of a wide variety of metal components used in autos, these blasters are typically a mainstay in many auto shops.

Using the appropriate protective gear, such as masks and goggles, is one safeguard in this process. This is due to the possibility of tiny particles and debris being released into the air, which can irritate and poison the eyes and lungs.

Using an Ultrasonic Cleaner

Jewelry has long been cleaned with these cleaners. They can probably remove damage from very sensitive materials that would otherwise be irreparable using other removal methods. This is perhaps the primary explanation for this.

Using this specific cleaner makes it simple to remove chrome. Sound waves are used by ultrasonic cleaners to strip metal of their chrome plating. Using a cleaner solution, the chrome-plated materials are placed in the ultrasonic cleaner basket for this process. It's well known that ultrasonic cleaners work well on small materials that are resistant to conventional chrome removal methods.

2. Chemical Solutions

In order to develop chrome plating, one must use an electric current to start chemical reactions. Conversely, certain chemicals can be used to remove chrome plating. A word of warning though: attempting to remove chrome from plastics with chemicals may result in the decomposition of the plastic itself. Furthermore, wearing protective clothing—especially gloves—is always a must.

3. Hydrochloric Acid

A powerful mineral acid with equally potent corrosive qualities is hydrochloric acid. Nonetheless, this corrosive quality is helpful when removing chrome from metals. Usually, high quantities of hydrochloric acid—roughly 30–40%—are utilized.

The chrome-plated item must be immersed in the acid solution and let to act by the acid in order to remove the coat. After some time, the chromium coating will fall off, and the acid solution should be properly disposed away. It may become damaged if the material is left in the concentrated hydrochloric acid solution longer than is necessary. Rinse and give the material a good wash with soap and water after removing the chrome. Allow to air dry.

Chemicals cannot be used to remove chromium from plastic materials. This is a result of many chemicals' extremely corrosive qualities, especially when applied in high concentrations to plastic materials. When making the hydrochloric acid solution, the same idea holds true. When making the acid solution, only use metal buckets or containers that can withstand the effects of the acid.

4. Sodium Hydroxide

Sodium hydroxide is the poster child for bases, just as hydrochloric acid is for acid solutions. It is possible to remove chrome plating off some metals by using a highly basic solution of sodium hydroxide.

Removing chrome-plated materials involves submerging them in the solution and letting it work, just like when employing acid solutions. As a result, the materials submerged in the solution likewise lose their chrome. The material then needs to be cleaned with soap and water, rinsed, and allowed to dry.

5. Reverse Electroplating

Yes, that is exactly what it sounds like: the electroplating process is reversed. But don't be duped—it's not nearly as simple as it seems! Additionally, this procedure should only be performed by experts due to its high level of danger and multiple poisonous and carcinogenic compounds.

Usually, a 100:1 acid to water mixture is used for reverse electroplating. Chromic and sulfuric acid are combined to get the final acid that is used. The temperature range for this procedure is 120–150F. The handler exposes the negative charge using a DC power source after temperature optimization. All of this is based on the idea of removing positive ions of chrome from the substance.

Rinse the material well under running water after removing the chrome, then let it dry.

It is recommended to leave the full chrome plating process to the pros for reasons of quality and safety. For these pros, Richconn is the ideal location!

We have been the top brand in the sector for 15 years and are experts in plating. Our skilled artisans and state-of-the-art processes ensure that every project receives the utmost care and precision, resulting in stunning, durable chrome finishes that exceed expectations. Compared to conventional plating, our plating is several times more resistant to rust. We always work to satisfy clients who seek out premium goods and have an impeccable methodology and quality control system.

Can only professionals perform chrome plating?

Although non-professionals can perform chrome plating at home, professionals like Richconn offer significantly higher quality than the amateurs do.

Is there any small parts chrome plating near me?

Yes, in our common electronic devices, such as mobile phones, computers, hard drives, etc., we may use small parts chrome plating. For example, connectors, interfaces, and various electronic components on circuit boards. These small parts can be effectively prevented from corrosion and wear and tear by chrome plating, thus extending the service life of the equipment and improving its performance.

Is it okay to remove chrome plating by sanding off the chrome?

This is totally dependent on the type of sandpaper used and the manner in which the handler sands the material. For sanding, 400-grit sandpaper works great. Experts should also sand metal surfaces. By doing this, the material's surface won't be defaced once the chrome coat is removed. Regarding product damage, there is not much to be concerned about if safeguards are taken correctly.

CNC Machining and 3D Printing - Friends or Foes?October 13, 2023The two technologies CNC machining and 3D printing have a major impact on many industries. But do they compete or complement each other?

Simply put, CNC machining is the inverse of 3D printing.view

CNC Machining and 3D Printing - Friends or Foes?October 13, 2023The two technologies CNC machining and 3D printing have a major impact on many industries. But do they compete or complement each other?

Simply put, CNC machining is the inverse of 3D printing.view CNC Machining Services and Engineered Machined Products: Meeting Manufacturing NeedsNovember 7, 2023Are you looking to understand the world of CNC machining and engineered machined products better? You're in the right place! I'm here to guide you through the intricate world of CNC machining, engineered machined products, and how Richconn can be your trusted partner in this journey.view

CNC Machining Services and Engineered Machined Products: Meeting Manufacturing NeedsNovember 7, 2023Are you looking to understand the world of CNC machining and engineered machined products better? You're in the right place! I'm here to guide you through the intricate world of CNC machining, engineered machined products, and how Richconn can be your trusted partner in this journey.view From Blueprint to Reality: The Role of 3D Printing in ArchitectureOctober 10, 2023The architecture industry is undergoing profound change thanks to 3D printing. Architects are harnessing this technology to revolutionize the way they design, construct and experience buildings. With 3D printing, architects can transform digital designs into tangible objects, opening up endless possibilities.view

From Blueprint to Reality: The Role of 3D Printing in ArchitectureOctober 10, 2023The architecture industry is undergoing profound change thanks to 3D printing. Architects are harnessing this technology to revolutionize the way they design, construct and experience buildings. With 3D printing, architects can transform digital designs into tangible objects, opening up endless possibilities.view Super-material carbon fiber: raw material production and its application and processingDecember 20, 2023Carbon fiber materials are used more and more widely, and their manufacturing is correspondingly accepted by more people. Price, capability and quality are all our advantages.view

Super-material carbon fiber: raw material production and its application and processingDecember 20, 2023Carbon fiber materials are used more and more widely, and their manufacturing is correspondingly accepted by more people. Price, capability and quality are all our advantages.view Welding Sheet Metal: How to Weld Sheet Metal? (Techniques & Tips)August 24, 2023Sheet metal welding is the process of using heat and electricity to join thin pieces of metal together. This process is essential for many applications, such as making custom products, repairing damag...view

Welding Sheet Metal: How to Weld Sheet Metal? (Techniques & Tips)August 24, 2023Sheet metal welding is the process of using heat and electricity to join thin pieces of metal together. This process is essential for many applications, such as making custom products, repairing damag...view What is a CNC machine? The Precision Way to Modern ManufacturingSeptember 21, 2023CNC machine stands for Computer Numerical Control, which is a manufacturing process that controls the movement of a tool or machine through a computer program.view

What is a CNC machine? The Precision Way to Modern ManufacturingSeptember 21, 2023CNC machine stands for Computer Numerical Control, which is a manufacturing process that controls the movement of a tool or machine through a computer program.view