When you think of an outstanding combination of material properties for parts, light weight and strength come to mind. Of course, the same is true for aluminum and titanium. Both materials meet other important criteria, such as excellent corrosion resistance and heat tolerance. Through 3D printing or precision CNC machining, these two metals have proven incredibly versatile for parts in diverse industries.

Aluminum and titanium are both lightweight, but for different reasons. Aluminum's low specific gravity (2.7 g/cm3) means it is much lighter than steel, which is about three times heavier. Although titanium is about two-thirds heavier than aluminum, its inherent strength means you need less of it. In fact, you need only a fraction of the amount of titanium to achieve the same physical strength as with aluminum. Titanium is used in aircraft engines, for example, and also in spacecraft. Its strength and light weight reduce fuel costs.

This table provides a technical overview of the types of aluminum and titanium we offer for DMLS and machining.

| Material | Proceedings | Tensile Strenght | Strain | Hardness | |

|---|---|---|---|---|---|

Aluminium (AlSi10Mg) | Annealed | DMLS | 240 MPa | 10% | 120 HB (~70 HRB) |

Aluminium 2024 | 3.1355 | AlCu4Mg1 | T351 | CNC | 430 MPa | 13% | 120 HB (~70 HRB) |

Aluminium 5083 | 3.3547 | AlMg4.5Mn0.7 | H111 | CNC | 300 MPa | 13% | 75 HB (~37HRB) |

Aluminium 6082 | 3.2315 | AlCu4Mg1 | T651 | CNC | 40 ksi (276 MPa) | 6% | 90 HB (~52 HRB) |

Aluminium 7075 | 3.4365 | AlZn5.5MgCu | T651 | CNC | 83 ksi (572 MPa) | 3 to 9% | 150 HB (~80 HRB) |

Aluminium 7075 | 3.4365 | AlZn5.5MgCu | T7351* | CNC | 500 MPa | 6 to 7% | 140 HB (~78 HRB) |

Titan (Ti 6Al-4V) | Annealed | DMLS | 1180 MPa | 10% | 33 HRC (~107 HRB) |

Titan (Grad 5 Ti 6Al-4V) | Annealed | CNC | 920 MPa | 15% | 35 HRC (~108 HRB) |

The big difference between your two options for machining aluminum has to do with the amount of copper in the alloy. If you need something with impressive strength that can handle high friction, 7075 makes the most sense. 6082 is better for welding, is easier to machine, and costs less. The most important thing when machining aluminum: When low weight, high heat tolerance and high strength are important, 7075 is the right choice.

Since both materials have high strength and low weight, it's important to consider other distinguishing characteristics when deciding which alloy to use for your parts.

Strength/Weight: In critical situations where every gram counts, but you still need strong parts, titanium is the first choice. Titanium medical components, complex satellite components, fixtures and brackets are so successful for this very reason.

Cost: Aluminum is the most cost-effective metal for machining or 3d printing prototype. While titanium adds cost, it can also add value. Lighter parts lead to fuel savings in transportation, and secondly, parts made from titanium simply last longer.

Thermal properties: Applications that require high thermal conductivity, such as a heat sink, benefit from aluminum. In high-temperature applications, titanium's high melting point benefits applications where heat resistance is a high priority, such as aerospace engine components.

Corrosion resistance: Both aluminum and titanium offer excellent corrosion resistance.

Due to its corrosion resistance and lack of reactivity, titanium is the most biocompatible metal, making it ideal for medical applications, such as surgical instruments. Ti 6-4 can also withstand salty environments and is often used in marine applications.

Aluminum is everywhere - it is the most common metal on our planet. The thin layer of aluminum oxide that forms when exposed to air makes it essentially corrosion-free, and its light weight helps keep your parts from acting like a ship's anchor. Although aluminum generally does not react to acids, it does tend to corrode in alkaline (basic) environments.

Generally, aluminum is used for aircraft and building materials, such as non-load-bearing frame structures. In particular, 6082 is the first choice for bicycle frames, SCUBA tanks, fishing reels, small boats and vehicle frames. The stronger properties of 7075 make it ideal for molds for plastics and tools, as well as aircraft frames. And if you're looking for a good electrical conductor, aluminum is the way to go. It can transfer heat optimally, making it an excellent material for heat sinks.

The aluminum alloy used in our DMLS (direct metal laser sintering) process, AlSi10Mg, also contains silicon and magnesium. It is commonly used for castings and most closely resembles a 3000 series alloy because it contains magnesium as the main alloying element. The properties of 3D-printed aluminum exceed those of its die-cast counterpart, except for lower elongation at break.

Titanium is also one of the most common metals on Earth, but its melting point is so high that it is difficult to process into a usable product. This is a key reason why it is more expensive than other metals. Parts made from titanium add cost because they are difficult to machine. Titanium is known for its strength and has a good strength-to-weight ratio. It also offers excellent corrosion resistance and is an equally poor electrical conductor.

One of the advantages of titanium is its low thermal expansion. With a melting point of about 1,660 degrees Celsius, it retains its shape better when exposed to heat. In addition, titanium does not absorb heat, but reflects it. Thus, you'll find it in low-E windows that bounce the sun's warming infrared rays.

As for appearance, the color of titanium varies depending on how much it has been altered. It can range from dull gray in raw form to shiny silver in smooth form. The titanium used in our DMLS process is Ti 6Al4V, better known as Ti 6-4. It has similar mechanical properties to Ti Grade 23 in the annealed condition and has exceptional tensile strength.

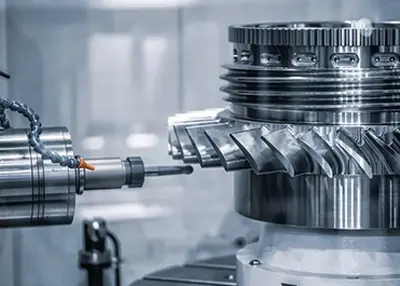

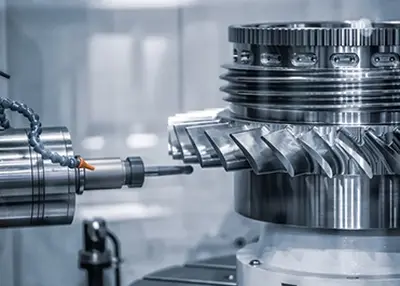

CNC milling and CNC turning are proven processes for producing aluminum and titanium parts. The processes are fast - often producing parts in less than a day - and they maintain tolerances of +/-0.1 mm. If you need a Manufacturing Rapid Prototyping Parts , aluminum stands out for its low cost and high quality. However, machining is somewhat limited in terms of geometries, so extremely complex designs require a different solution, such as DMLS, no matter what material you choose.

One factor you may not think about when selecting materials is machining waste. While milling off excess material is fine for inexpensive aluminum, it's not the ideal solution for expensive titanium. For this reason, engineers often choose to prototype aluminum and then switch to titanium for production parts. Machining aluminum is popular in the automotive industry, where lightweighting is key to improving fuel economy and minimizing performance impacts.

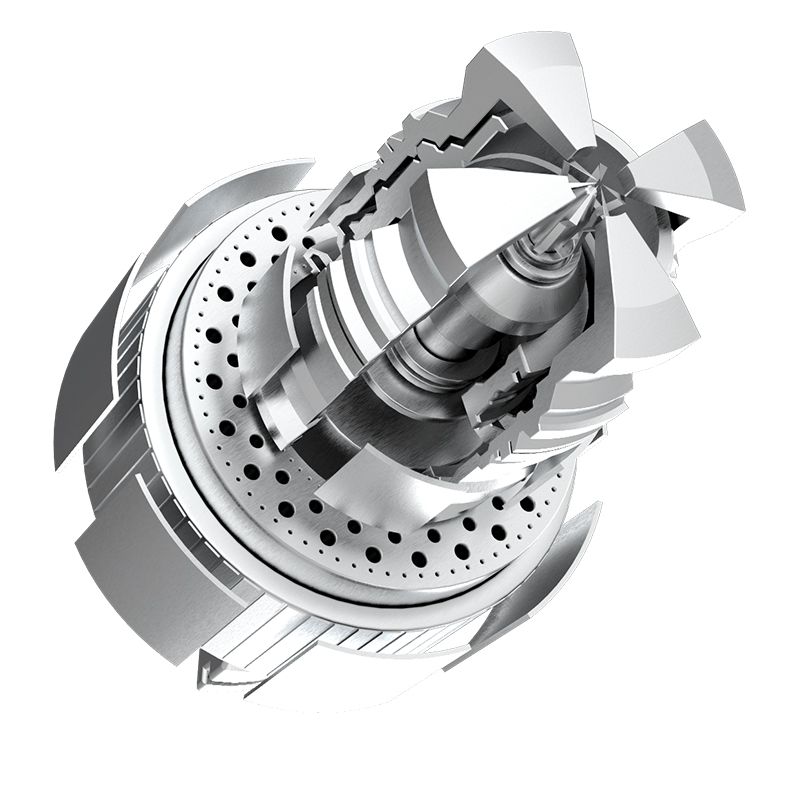

DMLS is an additive manufacturing process. A fusion laser is used to weld powdered metal and form it into parts layer by layer. The main advantage of DMLS is that you can create parts with incredibly complex geometries, such as honeycombs and mesh-like structures. Machining simply can't match the design flexibility of DMLS - regardless of the metal you choose.

If you need parts made from titanium, the cost of that material is a benefit you may not have thought of. Using powder means you have virtually no metal waste. In addition, while manufacturing costs are a bit higher with DMLS, the parts offer added value with the combination of strength and weight reduction. And an added bonus? With DMLS, you can combine separate parts of assemblies into a single, strong part. This saves time during assembly and reduces your bill of materials (BOM).

If you need further assistance, please contact a Richconn application engineer at +86-0755-28025755 or sales@richconn.com.cn. To get started on your next design project today, simply upload a 3D CAD model and receive an interactive quote within hours.

The Purpose and Importance of Metal Surface FinishApril 4, 2023Nowadays, metal surface finish technology is applied in many fields, which brings about innovation in metal surface finish and oil stain cleaning technology. Metal surface finish pretreatment is an in...view

The Purpose and Importance of Metal Surface FinishApril 4, 2023Nowadays, metal surface finish technology is applied in many fields, which brings about innovation in metal surface finish and oil stain cleaning technology. Metal surface finish pretreatment is an in...view 3-Axis Vs 4-Axis Vs 5-Axis CNCJuly 21, 20233-axis machiningThree axis CNC machining is the most basic, commonly used in the machinery manufacturing industry is one of the most important processing methods. Common understanding is: accurate lin...view

3-Axis Vs 4-Axis Vs 5-Axis CNCJuly 21, 20233-axis machiningThree axis CNC machining is the most basic, commonly used in the machinery manufacturing industry is one of the most important processing methods. Common understanding is: accurate lin...view 6 Considerations When Designing Parts For CNCOctober 11, 2023The fact is that when manufacturing parts through on-demand CNC machining, various aspects must be weighed against each other. After all, you wouldn't expect to buy a Bentley for the price of a Mini, but they both basically perform the same function and get us from point A to point B.view

6 Considerations When Designing Parts For CNCOctober 11, 2023The fact is that when manufacturing parts through on-demand CNC machining, various aspects must be weighed against each other. After all, you wouldn't expect to buy a Bentley for the price of a Mini, but they both basically perform the same function and get us from point A to point B.view Importance Of CNC Machining In Manufacturing Different PartsOctober 24, 2023CNC machining services help you to manufacture and fabricate different parts of metal as per the requirements. This process also helps in creating tolerances for various materials and metal parts. This process is usually a subtractive method of producing metal parts.view

Importance Of CNC Machining In Manufacturing Different PartsOctober 24, 2023CNC machining services help you to manufacture and fabricate different parts of metal as per the requirements. This process also helps in creating tolerances for various materials and metal parts. This process is usually a subtractive method of producing metal parts.view Cast Aluminum vs Machined Aluminum: Unveiling the Crafting MarvelsNovember 13, 2023In the realm of metal fabrication, the choice between cast aluminum and machined aluminum holds the key to unlocking a world of possibilities. As a CNC machining service provider, we, at Richconn, understand the importance of making informed decisions in the manufacturing process. Let's embark on a journey to explore the nuances of these two techniques, dissecting their processes, comparing their performance, and uncovering their diverse applications.view

Cast Aluminum vs Machined Aluminum: Unveiling the Crafting MarvelsNovember 13, 2023In the realm of metal fabrication, the choice between cast aluminum and machined aluminum holds the key to unlocking a world of possibilities. As a CNC machining service provider, we, at Richconn, understand the importance of making informed decisions in the manufacturing process. Let's embark on a journey to explore the nuances of these two techniques, dissecting their processes, comparing their performance, and uncovering their diverse applications.view Metal Gears vs Plastic Gears: Which Is the Better Option for Your Project?June 28, 2024What are the differences between metal gears and plastic gears? Which is the better option for your project? Let’s find the answers with the help of this article!view

Metal Gears vs Plastic Gears: Which Is the Better Option for Your Project?June 28, 2024What are the differences between metal gears and plastic gears? Which is the better option for your project? Let’s find the answers with the help of this article!view

EN

EN

ru

ru