Today, mechanization and automation have become mainstream in industry development. In the application process of machine equipment consisting of various parts, problems are prone to occur due to the lack of coordination or cooperation of certain parts. Raw material specifications, performance, material usage, machine vibration, clamping pressure or looseness, elastic deformation process system, worker operation, detection methods, and inspector errors all have an impact on the quality of processed products. When we talk about the quality of work prototypes, several main factors come to mind.

As CNC machining machines become more and more complex, there is a large difference in the level of programming and operating personnel skills. Combining human superior skills with computer information technology can maximize the use of the machine. Therefore, machine operators must be familiar with equipment performance. If the operator does not have enough understanding of the equipment performance, they may make mistakes, which will accelerate the wear and tear of machine components and even cause machine damage. Therefore, this will require a lot of maintenance costs and a longer maintenance time. CNC machine tool operators must understand and master the machine tool manual and its operating precautions to restore the equipment to its original accuracy and ensure civilized production and safe processing.

A complete CNC machining system is composed of machine tools, workpieces, fixtures, and cutting tools. The processing accuracy is related to the accuracy of the entire process system. Various errors in the process system will be reflected as different forms of machining tolerances under different circumstances. CNC machine accuracy is an important factor affecting the quality of prototype parts. When the machine precision is poor, and certain parts are damaged or the clearance between parts is not properly adjusted, various defects will appear in the prototype during the CNC machining process. Therefore, we not only need to choose the appropriate turning angle, cutting amount, and CNC machining method but also understand the influence of machine tool accuracy on the quality of OEM precision CNC machining. The maintenance of the machine directly affects the machining quality and production efficiency of the prototype. To ensure working accuracy and prolong its service life, all machines must be properly maintained. Usually, after the machine runs for 500 hours, first-level maintenance is required.

Service CNC has many methods of machining, and cutting processing is the most common one. During the cutting process, the workpiece undergoes force and heat changes, and the physical and mechanical properties of the metal material will also change slightly, so the choice of cutting tool is very important. Generally, the material for making the cutting tool should be selected according to the material of the machined workpiece. Otherwise, the surface of the workpiece will form burrs related to the cutting tool, which may increase the roughness of the workpiece surface and reduce the surface quality. In addition to the cutting tool factors, cutting environment and cutting processing conditions, such as cutting amount and cutting lubrication, also impact the machining quality. In the CNC machining process, the machining system is the overall commander of the entire cutting process. All CNC machining processes are executed according to the system, so the accuracy and rigidity of the machining system are also one of the main factors affecting the machining quality.

CNC machining materials are generally divided into plastics and metals. Each material has its own characteristics. It is also important to select the appropriate materials according to the requirements and applications of the workpiece during the machining process. The consistency of the material must be good; otherwise, the quality of the same part may differ. Try to keep the material from deforming as much as possible when the material hardness is appropriate. These are all important prerequisites for evaluating quality.

MIG Welding vs. TIG Welding: Choosing the Right Welding MethodSeptember 25, 2023MIG vs. TIG welding: Master the art, choose wisely. Explore techniques, applications, and trends for welding success.view

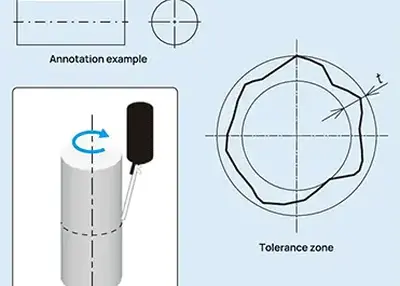

MIG Welding vs. TIG Welding: Choosing the Right Welding MethodSeptember 25, 2023MIG vs. TIG welding: Master the art, choose wisely. Explore techniques, applications, and trends for welding success.view Unveiling Precision: Exploring Roundness, GD&T, and Advanced Measurement TechniquesNovember 21, 2023Are you ready to delve into the world of precision engineering? Let's embark on a journey to unravel the intricacies of roundness, its symbiotic relationship with GD&T, and the cutting-edge techniques defining its measurement standards.view

Unveiling Precision: Exploring Roundness, GD&T, and Advanced Measurement TechniquesNovember 21, 2023Are you ready to delve into the world of precision engineering? Let's embark on a journey to unravel the intricacies of roundness, its symbiotic relationship with GD&T, and the cutting-edge techniques defining its measurement standards.view Aluminium Extrusion: A Versatile and Innovative Manufacturing ProcessNovember 30, 2023Aluminium extrusion is a process of forcing aluminium alloy material through a die to create a continuous shape or product. The material can be solid, liquid, or semi-solid, and it can be metal, plastic, ceramic, or food.view

Aluminium Extrusion: A Versatile and Innovative Manufacturing ProcessNovember 30, 2023Aluminium extrusion is a process of forcing aluminium alloy material through a die to create a continuous shape or product. The material can be solid, liquid, or semi-solid, and it can be metal, plastic, ceramic, or food.view Semiconductor Chip Carrier Manufacturing: Introduction from Materials to Finished ProductsAugust 14, 2023With the development of science and technology, semiconductor chips are being widely used in various fields. High quality chip carriers are crucial to ensure the performance of chips during semiconduc...view

Semiconductor Chip Carrier Manufacturing: Introduction from Materials to Finished ProductsAugust 14, 2023With the development of science and technology, semiconductor chips are being widely used in various fields. High quality chip carriers are crucial to ensure the performance of chips during semiconduc...view 5 Important Facts About 5 Axis Machining | Basics Information, Benefits, Limitations, Applications & TipsFebruary 20, 20245 axis CNC machining technology is important in manufacturing. Learn more about its basics, pros &cons, applications, and tips to enhance your project performance.view

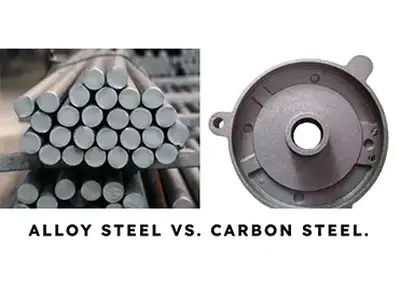

5 Important Facts About 5 Axis Machining | Basics Information, Benefits, Limitations, Applications & TipsFebruary 20, 20245 axis CNC machining technology is important in manufacturing. Learn more about its basics, pros &cons, applications, and tips to enhance your project performance.view Alloy Steel vs Carbon Steel: What are the Differences and Advantages?November 27, 2023Steel is one of the most widely used materials in various industries, such as construction, automotive, aerospace, and manufacturing. Steel is an alloy of iron and carbon, but it can also contain other elements to enhance its properties and performance.view

Alloy Steel vs Carbon Steel: What are the Differences and Advantages?November 27, 2023Steel is one of the most widely used materials in various industries, such as construction, automotive, aerospace, and manufacturing. Steel is an alloy of iron and carbon, but it can also contain other elements to enhance its properties and performance.view

EN

EN

ru

ru