As the proud owner of Richconn, a CNC machining service provider, I understand the importance of choosing the right manufacturing technology for your production needs. The decision between CNC machines and 3D printers can be a daunting one, and that's why I'm here to provide you with a comprehensive comparison to help you make an informed choice.

CNC (Computer Numerical Control) machines are known for their precision and versatility. These machines operate by removing material from a solid block, guided by a pre-programmed computer code. This subtractive manufacturing process allows for intricate and highly accurate part production, making CNC machines a staple in various industries.

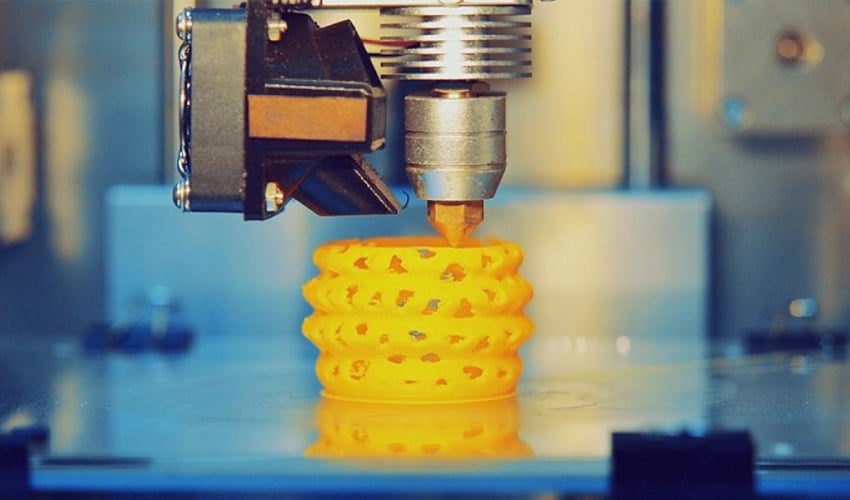

On the other hand, 3D printers, or additive manufacturing devices, create three-dimensional objects by layering material on top of each other. This additive process is known for its ability to produce complex geometries and is particularly useful for rapid prototyping and customized designs.

The choice of working principle can significantly affect the quality of your end product. CNC machines excel in achieving tight tolerances and smooth finishes, making them ideal for functional parts. 3D printers, while great for prototyping and customization, may have limitations when it comes to precision and surface finish.

To better illustrate the differences in working principles, let's break down the key characteristics in a table:

| Aspect | CNC Machine | 3D Printer |

|---|---|---|

| Operation Principle | Subtractive manufacturing | Additive manufacturing |

| Material Removal | Material is removed from a solid block | Material is added layer by layer |

| Precision | High precision, tight tolerances | Varies, may have limitations |

| Surface Finish | Smooth, high-quality finishes | Surface finish may require post-processing |

CNC machines are widely used in various industries due to their ability to create high-precision parts. Here are some key application areas:

Aerospace: CNC machining is crucial in aerospace manufacturing, producing parts with precise tolerances and reliability, such as engine components and structural elements.

Automotive: In the automotive industry, CNC machines are utilized to fabricate engine parts, transmission components, and custom automotive accessories.

Medical Devices: The medical field relies on CNC machining for creating intricate medical instruments, orthopedic implants, and prosthetic components.

Tool and Die Making: CNC machines are essential for producing molds, dies, and tooling used in various manufacturing processes.

Custom Parts: Many industries benefit from CNC machining to create bespoke parts tailored to their specific needs.

3D printing has gained popularity in industries that value customization and rapid prototyping. Here are some key application areas:

Jewelry: The jewelry industry uses 3D printing to produce intricate and unique designs that would be challenging to achieve with traditional methods.

Fashion: 3D printing allows for the creation of fashion accessories, clothing, and footwear with personalized designs.

Dental Care: In dentistry, 3D printing is employed to create custom dental implants, crowns, and orthodontic devices.

Architectural Models: Architects and designers use 3D printing to construct detailed architectural models that showcase intricate designs.

Art and Sculptures: Artists and sculptors can bring their creative visions to life through 3D printing, allowing for the production of complex and unique art pieces.

Understanding the current trends and industry demands is crucial when making a choice between CNC machines and 3D printers.

The CNC machining industry has seen continuous advancements in automation and precision, making it an attractive choice for high-volume production and applications demanding utmost accuracy.

Smart manufacturing, where CNC machines are integrated with data analytics and automation, is on the rise, enhancing efficiency and reducing production lead times.

3D Printer Trends

3D printing is gaining ground in the medical field for creating patient-specific implants and medical devices.

The fashion industry is embracing 3D printing to offer customers personalized and sustainable products.

By understanding these application areas and industry trends, you can better align your manufacturing needs with the technology that suits your specific requirements.

The initial investment in equipment is a significant consideration when choosing between CNC machines and 3D printers.

CNC machines can be costly to acquire, depending on the type and size of the machine. High-precision CNC mills and lathes, for example, often come with a higher price tag.

However, CNC machines are known for their durability and longevity, which can provide a good return on investment over time.

3D printers are available at a wide range of price points, from affordable desktop models to high-end industrial-grade machines. The cost largely depends on the printer's size, features, and printing capabilities.

Lower-end 3D printers can be relatively inexpensive, making them accessible to small businesses and hobbyists.

Maintaining your equipment is an ongoing expense that should not be overlooked.

CNC machines require regular maintenance, including routine inspections, lubrication, and the replacement of cutting tools or wear parts. These maintenance costs can add up over time.

However, proper maintenance ensures that CNC machines continue to operate at peak efficiency and produce high-quality parts.

3D printers generally have lower maintenance costs compared to CNC machines. Maintenance primarily involves cleaning, calibrating, and occasionally replacing print heads or build platforms.

The simplicity of maintenance contributes to the cost-effectiveness of 3D printing technology.

The type of materials used in your manufacturing process can have a significant impact on your overall expenses.

CNC machining often involves subtracting material from a larger block, which can result in material waste. This waste can add to the material costs, especially when working with expensive materials like metals.

Material costs are generally determined by the type of material and the quantity required for the job.

3D printing is more material-efficient, as it uses only the amount of material required to build the object. This reduces waste and can be cost-effective for certain applications.

Material costs for 3D printing vary depending on the material type, with options ranging from plastics to metals and more.

When choosing between CNC machines and 3D printers, it's essential to consider the return on investment (ROI).

The ROI of CNC machines can be high, particularly for businesses involved in high-volume production or applications that demand precision and reliability.

Over time, the initial equipment costs are often outweighed by the efficiency and quality of the produced parts.

3D printers offer excellent ROI potential for businesses focused on rapid prototyping, customization, and smaller production runs.

Lower equipment and maintenance costs, along with reduced material waste, can contribute to a quicker ROI for 3D printing technology.

Incorporating a financial analysis into your decision-making process is crucial for determining the most cost-effective manufacturing method for your specific needs. By considering equipment costs, maintenance expenses, material costs, and the potential for return on investment, you can make an informed choice that aligns with your budget and business goals.

CNC machining offers a wide range of materials that can be used to create precise and high-quality parts:

Metals: CNC machines are commonly used for machining metals such as aluminum, steel, brass, and titanium. These materials are known for their strength and durability.

Plastics: A variety of plastics, including ABS, PVC, and PEEK, can be machined with CNC technology. These materials are lightweight and offer different levels of rigidity.

Composites: CNC machining is also suitable for composites like carbon fiber reinforced polymers, which combine strength and lightness.

Ceramics: Some CNC machines can work with ceramics, which are valued for their hardness and resistance to wear.

Wood: CNC machining can craft intricate wooden components, making it useful in woodworking applications.

Foam and Compressed Foam: These materials can be machined for applications like packaging, insulation, and architectural design.

3D printing offers a variety of materials to choose from, each with unique properties and applications:

Plastics: PLA and ABS are among the most commonly used plastics for 3D printing. They are suitable for a wide range of applications, from prototypes to consumer goods.

Resins: Resin-based 3D printers can produce highly detailed and smooth-surfaced parts, making them ideal for jewelry and dental applications.

Metals: Metal 3D printing, using materials like stainless steel and titanium, is employed in aerospace, automotive, and medical industries for producing high-strength components.

Ceramics: 3D printing with ceramics is used for creating intricate and heat-resistant parts, especially in industries like aerospace and electronics.

Bio-Inks: In the medical field, bio-inks are used for 3D bioprinting, enabling the creation of tissue and organ structures for research and medical purposes.

The choice of material plays a crucial role in determining which technology is best suited for your project. Consider the characteristics of each material and its applicability:

Strength and Durability: For parts that require strength and durability, CNC machining with metals or composites may be more suitable. Metals are known for their high tensile strength and toughness.

Precision and Detail: If your project demands intricate details and smooth surfaces, 3D printing with resins can deliver exceptional results.

Customization: 3D printing excels in customization. You can easily adapt the design of a 3D-printed part to meet your specific requirements.

Heat Resistance: Materials like ceramics and certain plastics are heat-resistant and can withstand high temperatures, making them ideal for specific applications.

Material Diversity: CNC machining offers a wider range of materials, making it versatile for different industries. 3D printing is more specialized but offers unique material options.

Understanding the characteristics and applicability of materials is essential for making the right choice. Your selection should align with the requirements of your project, whether it's the strength and durability of CNC machining or the precision and customization of 3D printing.

CNC machines are known for their precision and speed, making them ideal for various industrial applications:

High Precision: CNC machines can achieve incredibly tight tolerances, ensuring the exact dimensions of the parts produced. This precision is crucial in industries where accuracy is paramount.

Rapid Production: CNC machines can produce parts at high speeds, making them suitable for large production runs. This efficiency is especially valuable in industries that require mass manufacturing.

High Material Removal Rates: CNC machines can rapidly remove material, enhancing productivity in applications like milling, drilling, and cutting.

3D printers vary in resolution and speed, depending on the type and model. Consider the following aspects:

Layer Resolution: 3D printers can achieve varying layer resolutions. Some models provide fine details with layer heights as small as 0.05 mm, while others prioritize speed over detail.

Printing Speed: The speed of 3D printing can vary significantly. Slower speeds may result in more precise prints, while faster speeds can increase production efficiency.

Quality vs. Speed: There's often a trade-off between print speed and print quality. Some applications may require sacrificing speed for better detail and vice versa.

When assessing CNC machines and 3D printers, it's crucial to look beyond the technical specifications and consider real-world performance:

Consider how CNC machines perform under actual working conditions, such as the type of material being processed, tool wear, and the complexity of the part.

CNC machines are often capable of maintaining high precision and speed over extended periods when properly maintained.

The real-world performance of a 3D printer can be influenced by factors like print settings, maintenance, and the quality of the material used.

Selecting the right 3D printer and optimizing print settings can help achieve the desired results.

By evaluating both the technical specifications and real-world performance of CNC machines and 3D printers, you can make an informed decision based on the specific requirements of your projects. Consider factors such as the need for high precision, production speed, and the trade-offs between quality and speed.

Assess the nature of your projects. Are they small-scale or large-scale? Do they require high precision or customization? Understanding your project's specifics is essential in choosing the right technology.

Consider the efficiency demands of your manufacturing process. If you need high-speed, mass production, CNC machining may be the better choice. For smaller runs and customization, 3D printing can be advantageous.

Evaluate the range of materials you require for your projects. If you need to work with various materials such as metals, plastics, or composites, CNC machining offers greater material diversity.

Understand your budget limitations and long-term investment plans. The initial equipment costs, maintenance expenses, and material costs should align with your financial goals.

Think about your future expansion plans. Ensure that the chosen technology can adapt to your growing needs and evolving market demands. Flexibility and scalability are vital considerations.

By carefully considering these factors, you can make an informed decision that aligns with your production goals, budget, and future growth plans. Whether you choose CNC machining or 3D printing, each technology has its unique strengths and capabilities that can be leveraged to meet your specific needs.

The decision between CNC machines and 3D printers is a significant one that will impact your production capabilities and costs. To make the right choice, thoroughly consider the working principles, application areas, costs, material and process factors, technical specifications, and the specific needs of your projects. By weighing these aspects, you can make an informed decision that aligns with your production goals, budget, and future growth plans.

I hope this article has provided you with valuable insights to make an informed decision. If you have any further questions or require additional information, please feel free to reach out. Thank you for choosing Richconn for your cnc machining services.

Aero-engine Why the Whole Leaf DiskOctober 23, 2023Aero-engine is the heart of the aircraft, also known as the pearl in the crown of industry, the manufacture of which integrates a lot of cutting-edge technology in modern industry, involving materials, machining, thermodynamics and other fields.view

Aero-engine Why the Whole Leaf DiskOctober 23, 2023Aero-engine is the heart of the aircraft, also known as the pearl in the crown of industry, the manufacture of which integrates a lot of cutting-edge technology in modern industry, involving materials, machining, thermodynamics and other fields.view Difference Between Hot Rolled and Cold RolledDecember 4, 2023Steel comes in a variety of grades, sizes, shapes and finishes - the World Steel Association lists more than 3,500 different grades of steel, most with unique properties. The variety of steel grades means that steel can be used in a wide range of applications for foundations, appliances, vehicles, wind turbines and many more.view

Difference Between Hot Rolled and Cold RolledDecember 4, 2023Steel comes in a variety of grades, sizes, shapes and finishes - the World Steel Association lists more than 3,500 different grades of steel, most with unique properties. The variety of steel grades means that steel can be used in a wide range of applications for foundations, appliances, vehicles, wind turbines and many more.view Powder Coating 101: What Is Powder Coating?August 14, 2023When seeking effective and durable finishing solutions for metal components, one term often comes up: "powder coating". The world of powder coating is full of mysteries. Whether you're c...view

Powder Coating 101: What Is Powder Coating?August 14, 2023When seeking effective and durable finishing solutions for metal components, one term often comes up: "powder coating". The world of powder coating is full of mysteries. Whether you're c...view What is Metal Machining?November 3, 2023When it comes to shaping the world around us, few processes play as pivotal a role as metal machining. Whether you're a curious enthusiast or an industry professional seeking deeper insights, this article is your ultimate guide to understanding the essence of metal machining.view

What is Metal Machining?November 3, 2023When it comes to shaping the world around us, few processes play as pivotal a role as metal machining. Whether you're a curious enthusiast or an industry professional seeking deeper insights, this article is your ultimate guide to understanding the essence of metal machining.view Which Is Easier to Weld, Aluminum or Stainless Steel?October 26, 2023This is because the melting point of stainless steel is higher than that of aluminum alloys, which makes it more stable during the welding process. Aluminum alloys are prone to the risk of being burned through because of their low melting point during the welding process. In addition, aluminum alloys are also susceptible to the formation of an aluminum oxide film on the surface in air, which has a much higher melting point than aluminum itself, making it more difficult to weld.view

Which Is Easier to Weld, Aluminum or Stainless Steel?October 26, 2023This is because the melting point of stainless steel is higher than that of aluminum alloys, which makes it more stable during the welding process. Aluminum alloys are prone to the risk of being burned through because of their low melting point during the welding process. In addition, aluminum alloys are also susceptible to the formation of an aluminum oxide film on the surface in air, which has a much higher melting point than aluminum itself, making it more difficult to weld.view 6 Considerations When Designing Parts For CNCOctober 11, 2023The fact is that when manufacturing parts through on-demand CNC machining, various aspects must be weighed against each other. After all, you wouldn't expect to buy a Bentley for the price of a Mini, but they both basically perform the same function and get us from point A to point B.view

6 Considerations When Designing Parts For CNCOctober 11, 2023The fact is that when manufacturing parts through on-demand CNC machining, various aspects must be weighed against each other. After all, you wouldn't expect to buy a Bentley for the price of a Mini, but they both basically perform the same function and get us from point A to point B.view