Even a perfectly designed injection molded part can potentially disappoint if it is made from the wrong material. It is often difficult to select the right materials from hundreds of thermoplastics and elastomers to meet the requirements of the application. A variety of factors, such as mechanical strength, UV resistance, lubricity, wear resistance, and chemical and UV resistance should be carefully considered when selecting materials for injection molding.

In 2K injection molding, there are additional challenges, as designers must not only adhere to standard injection molding design principles, but also pay attention to the strength and durability of the chemical and physical bonds between the chosen materials. This design tip highlights three important aspects designers should be familiar with when designing injection molded parts - material compatibility, adhesion and tribology.

Let's start with a term you don't hear too often in manufacturing. Tribology deals with friction and wear between two surfaces that move against each other. An example is the clip and tongue of a snap-top container. An engineer concerned with the tribology of parts would likely be less concerned with the chemical and mechanical bonds required to overmold a handle for a power tool (since these components do not move against each other when validly designed) and more concerned with the feel and grip of the overmold material itself.

In the snap-on fastener example, a wear-resistant polymer such as HDPE would be a good choice, although a relatively slippery material such as acetal could also be considered here. Both materials have their own merits, which should be carefully weighed against each other in the early stages of the development process. The product design itself can be an important factor in tribological behavior. Surfaces that interact with each other should be as smooth as possible, because small bumps and dimples on rough surfaces can catch on each other, causing breakage with repeated use.

The manufacturing method also plays a role. In the example of the clip, which can be easily transferred to other plastic parts with mating or interlocking surfaces, a machined surface is different from a fast 3D prints. An injection-molded surface, in turn, has different properties (and is probably smoother than the other two). If part interaction is a design concern, part properties should be analyzed and tested as early as possible.

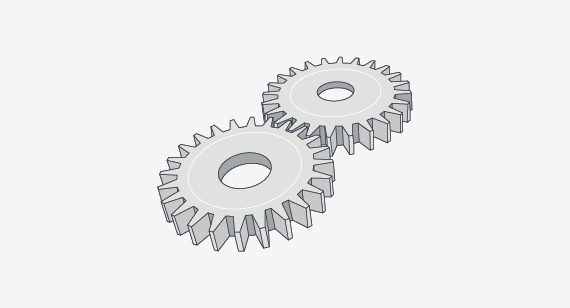

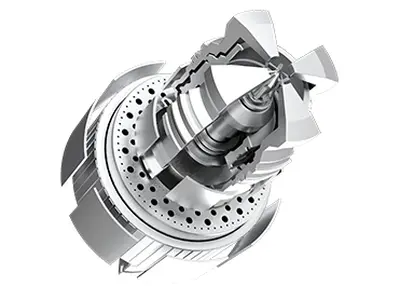

These intermeshing plastic gears are intended to illustrate how part design, through friction and wear between two interacting surfaces, can be affected. This is an important aspect to consider when selecting materials for your injection molded parts.

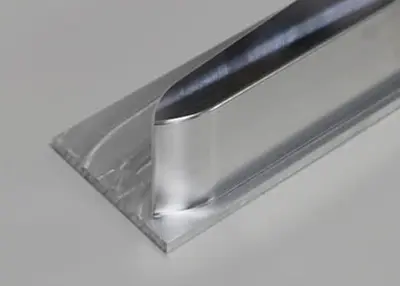

Another example: metal inserts are a popular option at Richconn. Whether it's a bronze bushing in an injection-molded fan blade, a stainless steel sleeve in a plastic pulley, or a threaded brass nut in an appliance knob, such inserts can be easily incorporated into injection-molded parts. Material compatibility plays a subordinate role here. The biggest hurdle for the designer is to ensure that a strong mechanical bond is created when the insert is overmolded and overmolded with plastic. In this regard, bronze and brass make good, low-cost bearing surfaces, but are more prone to wear than ball bearings. Ask yourself this question: will your design meet the long-term requirements of the product? A good understanding of friction characteristics will help answer this and other important questions.

Few would dispute that 2K injection molding is one of the most useful developments in plastics manufacturing since rapid injection molds. It is a great option when a soft or user-friendly material is needed on a structural core - as in the handle of an instrument or the housing of a portable electronic device - or where multiple colors are desired for aesthetic reasons. You can find a lot of information on the Internet about designing for 2K injection molding that addresses both the need for a durable mechanical bond and the chemical compatibility between two materials in contact.

Fortunately, the selection of chemically compatible materials is wide. For example, Richconn offers TPV Sarlink 3170, a thermoplastic elastomer that forms a strong chemical bond with polypropylene. Another option is TPC Hytrel 4068, also a thermoplastic elastomer that is very compatible with ABS, polycarbonate and other materials. In contrast, nylon is one of the more difficult substrates for 2K injection molding because it tends to absorb moisture. Nevertheless, it is used for a variety of applications.

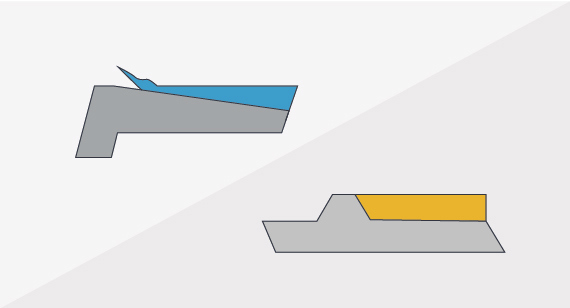

However, there are other aspects that must be considered. Part design can have significant impact on the strength of adhesion for 2K injection molded parts. The transition between substrate and coating must be abrupt to prevent leakage or thinning. A groove or shoulder can be used here to provide a clear demarcation. Curling and potential tearing can be avoided by placing the form-fit at a point that provides a hard stop for soft, pliable and very flowable TPE. If the overlay is too thin - say, less than 1/16 inch (1.59 mm) thick - the material could cool too quickly, affecting adhesion. If the length-to-thickness ratio is high, similar problems can occur.

With 2K injection molding, you also need to consider the specific thermal properties of both materials. You may choose silicone (LSR) for its excellent heat and chemical resistance, low-temperature pliability and inherent lubricity. However, it is important to note that LSR requires temperatures of 150 to 200 degrees Celsius to cure, which ABS, polyethylene, polypropylene and other materials cannot withstand. Venting is also important because burners, insufficient adhesion and incomplete mold filling - known as "short shots" - can occur in inadequately vented molds.

Chemical adhesion in 2K injection molding has its pitfalls. The transition between substrate and coating must be abrupt to prevent leakage or thinning. Create a clear boundary by using a groove or shoulder. Curling and tearing can be avoided by placing the form-fit at a point that creates a hard stop for soft flowable TPE. The figure on the left shows the substrate in gray and the TPE and potential curl in blue. On the right, the substrate is shown in gray and the TPE in yellow. Here, the TPE is held in place by the form fit.

The compatibility chart available online is very clear, but if you want to provide your own material, it is best to consult your plastics supplier for moldability and application. This is especially true if you are using an application-specific polymer blend, as more and more Richconn customers are doing. Colorants can affect adhesion, as can high levels of additives such as metal or glass. Therefore, we always advise to make a few sample parts first and test them thoroughly before commissioning whole series.

There are countless examples and endless polymer combinations. That's why it's important to get expert advice on the pitfalls of adhesion and chemical compatibility of polymers at the beginning of the design process. This is the only way to ensure that a) the chosen materials will get along well, b) the part or 2K combination is feasible according to the design, and c) the tribological properties are right, meaning that the chosen materials are slippery, wear-resistant, or adhesive enough for the product's purpose.

Here it is particularly important to follow Richconn' recommendations. A plastic with a high additive content may meet the requirements for your product, but on the other hand, the time required for product design may be greater. Moldability decreases as additive content increases, and complex parts present additional challenges.

Not to worry. All of these challenges can be overcome with focused attention on the design process and a review of material selection. When in doubt, let Richconn advise you - even if you are still at the beginning of your design phase. With the help of our expert staff, automated quoting process, and free formability analysis, even chemically challenging materials can be handled with ease.

As always, if you have any questions or comments, please feel free to contact our application engineers at +86-0755-28025755 or send an email to sales@richconn.com.cn to get in touch with one of our Customer Service representatives.

How to remove chrome plating from sheet metal?November 24, 2023Chrome plating is a common metal finish that improves the wear resistance, corrosion resistance, aesthetics and hardness of the metal.view

How to remove chrome plating from sheet metal?November 24, 2023Chrome plating is a common metal finish that improves the wear resistance, corrosion resistance, aesthetics and hardness of the metal.view What Is Galvanized Sheet Metal? The Complete Basics to Get StartedOctober 12, 2023Galvanized sheet metal is one of the most cost-effective and popular types of metal in the market. Here are the complete basics about it for you to get started.view

What Is Galvanized Sheet Metal? The Complete Basics to Get StartedOctober 12, 2023Galvanized sheet metal is one of the most cost-effective and popular types of metal in the market. Here are the complete basics about it for you to get started.view What Industries Use Stainless Steel?October 27, 2023Stainless steel is the abbreviation of stainless and acid-resistant steel, air, steam, water and other weak corrosive media or with stainless steel is called stainless steel, and will be resistant to chemical corrosive media (acids, alkalis, salts and other chemical corrosion) corrosion of the steel is called acid-resistant steel.view

What Industries Use Stainless Steel?October 27, 2023Stainless steel is the abbreviation of stainless and acid-resistant steel, air, steam, water and other weak corrosive media or with stainless steel is called stainless steel, and will be resistant to chemical corrosive media (acids, alkalis, salts and other chemical corrosion) corrosion of the steel is called acid-resistant steel.view CNC Machined Bottle Openers: Elevating Craftsmanship with Richconn PrecisionNovember 14, 2023Welcome to the realm where precision meets innovation – Richconn's CNC machined bottle openers redefine the art of craftsmanship. As a leading CNC machining service provider, Richconn is committed to delivering not just bottle openers, but a symphony of precision, design excellence, and user satisfaction.view

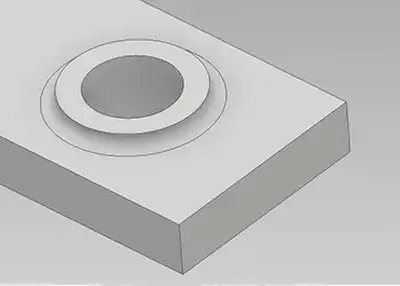

CNC Machined Bottle Openers: Elevating Craftsmanship with Richconn PrecisionNovember 14, 2023Welcome to the realm where precision meets innovation – Richconn's CNC machined bottle openers redefine the art of craftsmanship. As a leading CNC machining service provider, Richconn is committed to delivering not just bottle openers, but a symphony of precision, design excellence, and user satisfaction.view What is a Machined Boss: A Comprehensive GuideNovember 8, 2023In the world of precision engineering, the term machined boss may not be a household name, but it is undoubtedly a crucial element that underpins countless industries. Whether you're a novice looking to expand your knowledge or a seasoned professional seeking in-depth insights, this article will serve as your comprehensive guide to understanding what a machined boss is, how it works, and why it matters.view

What is a Machined Boss: A Comprehensive GuideNovember 8, 2023In the world of precision engineering, the term machined boss may not be a household name, but it is undoubtedly a crucial element that underpins countless industries. Whether you're a novice looking to expand your knowledge or a seasoned professional seeking in-depth insights, this article will serve as your comprehensive guide to understanding what a machined boss is, how it works, and why it matters.view Unlocking Precision: Exploring the Parts of a CNC MachineSeptember 22, 2023Are you ready to dive into the world of CNC (Computer Numerical Control) machines? If you're fascinated by precision engineering and the wonders it can achieve, you've come to the right place.view

Unlocking Precision: Exploring the Parts of a CNC MachineSeptember 22, 2023Are you ready to dive into the world of CNC (Computer Numerical Control) machines? If you're fascinated by precision engineering and the wonders it can achieve, you've come to the right place.view

EN

EN

ru

ru