Plastics are widely used materials in various industries, such as packaging, automotive, medical, and consumer products. Plastics are synthetic or semi-synthetic polymers that can be molded or shaped into different forms and products. There are many types and grades of plastics, each with different chemical compositions and physical properties. Among them, ABS (acrylonitrile butadiene styrene) and PP (polypropylene) are two common plastics that have similar characteristics, but also have some differences that affect their applications and performance.

The main difference between ABS and PP is the type and arrangement of the monomers that make up their polymer chains. Monomers are the basic units that are linked together to form polymers. ABS is a copolymer, which means it is made of three different monomers: acrylonitrile, butadiene, and styrene. PP is a homopolymer, which means it is made of only one type of monomer: propylene.

| Plastic | Monomer(s) | Composition (%) |

|---|---|---|

| ABS | Acrylonitrile, Butadiene, Styrene | 15-35, 5-30, 40-60 |

| PP | Propylene | 100 |

The different monomers give ABS and PP different properties and characteristics. Acrylonitrile gives ABS strength, stiffness, and chemical resistance. Butadiene gives ABS toughness, impact resistance, and flexibility. Styrene gives ABS gloss, rigidity, and processability. Propylene gives PP high crystallinity, low density, and high melting point.

The properties of ABS and PP depend on their composition, molecular structure, and processing methods. Different additives, fillers, reinforcements, or blends can also modify the properties of ABS and PP. The table below shows some typical physical and mechanical properties of ABS and PP:

| Property | Unit | ABS | PP |

|---|---|---|---|

| Density | g/cm³ | 1.04-1.10 | 0.90-0.91 |

| Melting Point | °C | 200-250 | 160-170 |

| Glass Transition Temperature | °C | 105 | -10 |

| Tensile Strength | MPa | 40-50 | 30-40 |

| Flexural Strength | MPa | 60-70 | 40-50 |

| Elongation at Break | % | 15-25 | 100-600 |

| Impact Strength | kJ/m² | 15-20 | 3-5 |

| Hardness | Shore D | 75-85 | 60-70 |

| Thermal Expansion Coefficient | 10^-6/°C | 70-80 | 100-150 |

| Thermal Conductivity | W/mK | 0.17-0.19 | 0.10-0.22 |

| Electrical Resistivity | Ωm | 10^14-10^16 | 10^16-10^18 |

From the table, we can see that ABS has higher density, melting point, glass transition temperature, tensile strength, flexural strength, impact strength, and hardness than PP, but lower elongation at break, thermal expansion coefficient, and electrical resistivity than PP. This indicates that ABS is more suitable for applications that require high strength, stiffness, and heat resistance, while PP is more suitable for applications that require high flexibility, low weight, and electrical insulation.

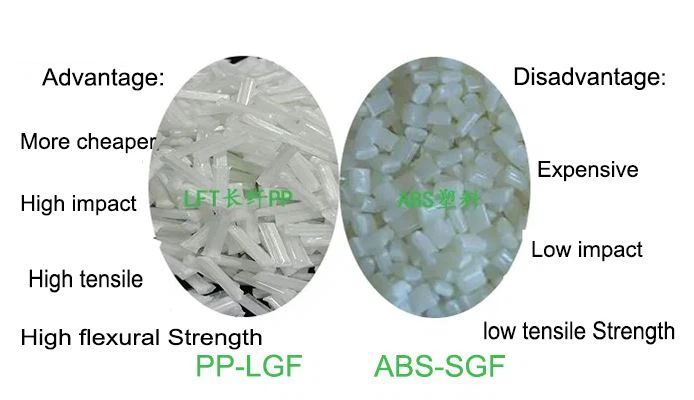

Both ABS and PP have their own advantages and disadvantages, depending on their properties and applications. Here are some of the main advantages and disadvantages of ABS and PP:

• ABS: ABS is a low-cost plastic that has good mechanical properties, such as durability, rigidity, and impact resistance. ABS also has good chemical resistance, electrical insulation, and dimensional stability. ABS is easy to process, mold, and fabricate, and can be modified with additives, fillers, reinforcements, or blends to enhance its properties. However, ABS also has some disadvantages, such as low heat resistance, poor weatherability, high flammability, and high shrinkage. ABS is also prone to warping, cracking, and stress whitening during processing or use.

• PP: PP is a low-cost plastic that has good mechanical properties, such as flexibility, toughness, and fatigue resistance. PP also has good chemical resistance, electrical insulation, and moisture resistance. PP is easy to process, mold, and fabricate, and can be modified with additives, fillers, reinforcements, or blends to enhance its properties. However, PP also has some disadvantages, such as low strength, stiffness, and heat resistance, poor UV resistance, high flammability, and low surface hardness. PP is also prone to oxidation, degradation, and creep during processing or use.

The uses of ABS and PP depend on their properties and prices. Different plastics are suitable for different fields and industries. Here are some examples of the uses of ABS and PP:

• ABS: Due to its good mechanical properties, chemical resistance, and electrical insulation, ABS is mainly used for applications that require high performance and durability, such as automotive, electronics, medical, and consumer products. Some examples of ABS products are bumpers, dashboards, keyboards, monitors, housings, cases, helmets, toys, etc.

• PP: Due to its good mechanical properties, chemical resistance, and moisture resistance, PP is mainly used for applications that require high flexibility and low weight, such as packaging, textiles, furniture, and household products. Some examples of PP products are bottles, containers, bags, films, fibers, carpets, chairs, plates, etc.

ABS and PP are two different plastics, they have the following main differences and advantages:

• ABS is a copolymer made of three different monomers, while PP is a homopolymer made of only one type of monomer.

• ABS has higher density, melting point, glass transition temperature, tensile strength, flexural strength, impact strength, and hardness than PP, but lower elongation at break, thermal expansion coefficient, and electrical resistivity than PP.

• ABS is more suitable for applications that require high strength, stiffness, and heat resistance, while PP is more suitable for applications that require high flexibility, low weight, and electrical insulation.

• ABS and PP both have advantages and disadvantages, such as low cost, good chemical resistance, easy processing, low heat resistance, poor weatherability, high flammability, etc.

• ABS and PP are widely used for various applications, such as automotive, electronics, medical, consumer, packaging, textiles, furniture, household, etc.

If you are looking for a reliable and professional plastic CNC machining service, I recommend you to check out Richconn, a leading custom precision machining factory that can provide you with high-quality ABS and PP machining service, as well as other plastics and metals. Richconn has rich experience and advanced equipment to meet your design requirements and application needs. You can visit our website or contact their online customer service for a free quote and consultation. I hope you can find the best solution for your plastic products. blush

Better CNC Parts Through Fine tuning of TolerancesOctober 13, 2023Tolerances that are too tight can require rework, which in turn drives up costs. If tolerances are too loose, the part may not fit with the mating part. So to optimize your designs, know what tolerances are needed and when: Standard tolerances can improve quality, ensure fast repeatability and reduce manufacturing costs.view

Better CNC Parts Through Fine tuning of TolerancesOctober 13, 2023Tolerances that are too tight can require rework, which in turn drives up costs. If tolerances are too loose, the part may not fit with the mating part. So to optimize your designs, know what tolerances are needed and when: Standard tolerances can improve quality, ensure fast repeatability and reduce manufacturing costs.view Machined Washers: Everything You Need to Know About CNC-Engineered FastenersNovember 8, 2023Welcome to the world of machined washers! If you're reading this, you're about to embark on a journey to discover the fundamental building blocks of precision engineering. Whether you're an engineer, a DIY enthusiast, or a professional seeking the perfect fastener for your project, this comprehensive guide will equip you with the knowledge to make informed decisions and take your projects to the next level.view

Machined Washers: Everything You Need to Know About CNC-Engineered FastenersNovember 8, 2023Welcome to the world of machined washers! If you're reading this, you're about to embark on a journey to discover the fundamental building blocks of precision engineering. Whether you're an engineer, a DIY enthusiast, or a professional seeking the perfect fastener for your project, this comprehensive guide will equip you with the knowledge to make informed decisions and take your projects to the next level.view Rapid Prototyping for Every Phase of Product DevelopmentOctober 11, 2023Time to market is critical to your competitive advantage. However, forgoing prototyping is a big risk that can cost you production costs, lost revenue, and your reputation if your product doesn't...view

Rapid Prototyping for Every Phase of Product DevelopmentOctober 11, 2023Time to market is critical to your competitive advantage. However, forgoing prototyping is a big risk that can cost you production costs, lost revenue, and your reputation if your product doesn't...view Electrophoretic Coating Process Details and Electrophoretic Paint Selection GuideJune 17, 2024Electrophoretic Coating is a cutting-edge technology that has revolutionized the manufacturing landscape. By offering consistent, uniform surface coverage along with unmatched durability and corrosion...view

Electrophoretic Coating Process Details and Electrophoretic Paint Selection GuideJune 17, 2024Electrophoretic Coating is a cutting-edge technology that has revolutionized the manufacturing landscape. By offering consistent, uniform surface coverage along with unmatched durability and corrosion...view Unlocking the Secrets of Spline Machining: A Comprehensive GuideNovember 15, 2023In the intricate world of manufacturing, the precision required for creating components like splines demands a deep understanding of machining processes. In this comprehensive guide, we embark on a detailed exploration of the art and science behind spline machining, unraveling its complexities and unveiling the techniques that shape these vital engineering elements.view

Unlocking the Secrets of Spline Machining: A Comprehensive GuideNovember 15, 2023In the intricate world of manufacturing, the precision required for creating components like splines demands a deep understanding of machining processes. In this comprehensive guide, we embark on a detailed exploration of the art and science behind spline machining, unraveling its complexities and unveiling the techniques that shape these vital engineering elements.view Difference Between Hot Rolled and Cold RolledDecember 4, 2023Steel comes in a variety of grades, sizes, shapes and finishes - the World Steel Association lists more than 3,500 different grades of steel, most with unique properties. The variety of steel grades means that steel can be used in a wide range of applications for foundations, appliances, vehicles, wind turbines and many more.view

Difference Between Hot Rolled and Cold RolledDecember 4, 2023Steel comes in a variety of grades, sizes, shapes and finishes - the World Steel Association lists more than 3,500 different grades of steel, most with unique properties. The variety of steel grades means that steel can be used in a wide range of applications for foundations, appliances, vehicles, wind turbines and many more.view

EN

EN

ru

ru