ABS (Acrylonitrile Butadiene Styrene Copolymer) is a common general-purpose thermoplastic 3D printing plastic, characterized by high strength, good toughness, excellent impact resistance, a certain degree of temperature resistance (around 80-90 ℃), it also has high dimensional stability and a certain degree of chemical resistance, it is one of the engineering plastics with more industrial applications.

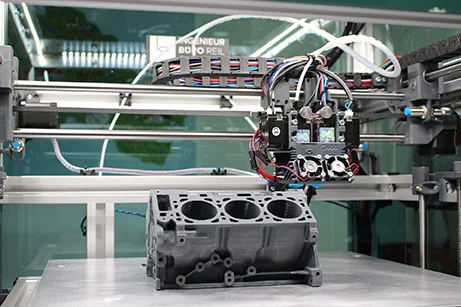

Applications: engineering design, prototyping, functional testing, parts assembly, product shells, toys, car bodies, etc.

EN

EN

ru

ru