Black as a color has always captivated and fascinated humans. It is mysterious, elegant, and striking, making it a popular choice for various applications. From fashion and design to technology and engineering, black is a timeless shade that symbolizes sophistication and exclusivity. But have you ever wondered how black is created on different surfaces? Enter the world of surface treatments, specifically blackening surface treatment, where chemistry plays a crucial role in achieving that perfect black finish. In this blog, we will explore the science behind black and various surface treatments that produce this coveted color.

Black has always been associated with sophistication, style, and elegance. Its timeless appeal transcends industries, making it a sought-after color for a wide range of products. In fashion and design, black is known for its ability to create a slimming effect and convey a sense of power and authority. But what makes black so captivating? It is all about light absorption. Unlike other colors that reflect light, black absorbs nearly all wavelengths of light, creating an illusion of depth and intensity. This unique property makes black visually striking and appealing to the human eye.

Surface treatments are an essential part of manufacturing processes across various industries. Not only do they enhance the aesthetics of a product, but they also improve its functionality, durability, and resistance to wear and corrosion. Surface treatments like blackening help protect metals from oxidation, increasing their lifespan and maintaining their appearance. Black finishes not only offer an appealing and elegant appearance, but they also provide excellent camouflage for specific applications, such as military equipment or theatrical props. Additionally, surface treatments can also improve a material's ability to absorb or reflect heat, making them suitable for industries like aerospace and automotive.

Blackening surface treatment, also known as black oxide coating, is a chemical process that involves converting the top layer of metal into a stable black oxide. This process not only enhances the aesthetics of the material but also improves its corrosion resistance. The black oxide layer is formed through a controlled chemical reaction between the metal surface and a hot alkaline or acidic solution. This reaction results in the formation of a black iron oxide or magnetite layer that adheres tightly to the metal. The thickness and quality of the black oxide coating can be controlled by adjusting the temperature, time, and concentration of the solution.

The blackening process offers several advantages over other surface treatment methods. Unlike paint or other coatings, blackening doesn't add any significant thickness or alter the dimensions of the metal. It forms a chemical bond with the metal surface, providing excellent adhesion and preserving the material's original properties. Furthermore, blackening enhances the hardness, lubricity, and electrical conductivity of the metal, making it suitable for a wide range of applications and industries.

Black is a captivating color that symbolizes sophistication and exclusivity. Surface treatments, particularly blackening surface treatment, allow us to achieve that perfect black finish on various materials. Understanding the chemistry behind blackening helps us appreciate the complex processes involved in creating this striking color. Whether it's for aesthetics or functionality, blackening surface treatment offers a durable and visually pleasing solution across different industries. So, the next time you see a perfectly blackened surface, remember the intricate chemistry that brings it to life.

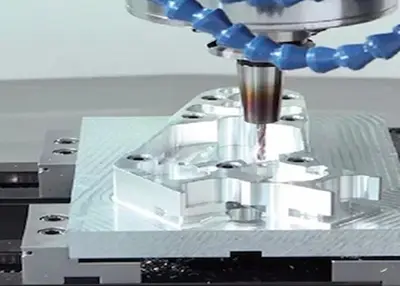

CNC Machine Cost - Your Comprehensive Guide to Understanding and Navigating CostsNovember 2, 2023In today's fast-paced manufacturing world, the utilization of CNC (Computer Numerical Control) machines has become pivotal for businesses and hobbyists alike. These automated tools offer unparalleled precision and efficiency in various industries, from automotive to aerospace, and even the creation of intricate custom components. However, one question looms large for anyone considering CNC machining: What are the costs involved?view

CNC Machine Cost - Your Comprehensive Guide to Understanding and Navigating CostsNovember 2, 2023In today's fast-paced manufacturing world, the utilization of CNC (Computer Numerical Control) machines has become pivotal for businesses and hobbyists alike. These automated tools offer unparalleled precision and efficiency in various industries, from automotive to aerospace, and even the creation of intricate custom components. However, one question looms large for anyone considering CNC machining: What are the costs involved?view The Role of CNC Machining in the Automotive IndustryApril 25, 2023CNC machining is commonly used for complex designs, small products, and parts. Through CNC machine tools, a variety of parts can be machined more accurately.With the rapid development of the automotiv...view

The Role of CNC Machining in the Automotive IndustryApril 25, 2023CNC machining is commonly used for complex designs, small products, and parts. Through CNC machine tools, a variety of parts can be machined more accurately.With the rapid development of the automotiv...view Find the Right Corrosion Resistant MetalsOctober 16, 2023Without oxygen, no living thing could exist on Earth. Yet it is indeed a toxic, highly corrosive gas that can even be used to propel rockets into space. Our bodies make use of oxygen in impressive ways. The fact that the air we breathe contains only a relatively small proportion of the gas - about 21 percent oxygen compared with 78 percent nitrogen - also helps keep us alive.view

Find the Right Corrosion Resistant MetalsOctober 16, 2023Without oxygen, no living thing could exist on Earth. Yet it is indeed a toxic, highly corrosive gas that can even be used to propel rockets into space. Our bodies make use of oxygen in impressive ways. The fact that the air we breathe contains only a relatively small proportion of the gas - about 21 percent oxygen compared with 78 percent nitrogen - also helps keep us alive.view In-depth Understanding of Five-axis CNC Service ProcessingOctober 24, 2022When it comes to cnc machining services, you will definitely think of 5-axis CNC machining. Choosing the right machining solution will lead to a successful production. CNC machining is a procedure use...view

In-depth Understanding of Five-axis CNC Service ProcessingOctober 24, 2022When it comes to cnc machining services, you will definitely think of 5-axis CNC machining. Choosing the right machining solution will lead to a successful production. CNC machining is a procedure use...view The Complete Guide to CNC Machining Parts: Types, Advantages & DesignApril 3, 2024The following is a thorough introduction to CNC machining parts, which is of great importance for your project. Let’s have a deeper look at these machined parts!view

The Complete Guide to CNC Machining Parts: Types, Advantages & DesignApril 3, 2024The following is a thorough introduction to CNC machining parts, which is of great importance for your project. Let’s have a deeper look at these machined parts!view Anodized Aluminum: A Durable and Versatile MaterialJuly 27, 2023Anodized aluminum is a metal with widespread use and advantages. It is a process of treating metal with electricity to create an oxide protective layer on the surface. This layer helps to protect alum...view

Anodized Aluminum: A Durable and Versatile MaterialJuly 27, 2023Anodized aluminum is a metal with widespread use and advantages. It is a process of treating metal with electricity to create an oxide protective layer on the surface. This layer helps to protect alum...view

EN

EN

ru

ru